Connect Commercial Sensor to BoSL

Introduction

While our self-developed BoSL low-cost sensors offer versatile, flexible, and affordable solutions to the highly spatially distributed real-time water monitoring campaigns, the high-end commercial sensors are sometimes still needed in accordance with the special requirements of these monitoring campaigns. Usually, a data logger is required to couple with these sensors at a monitoring location to collect and store the sensor data. However, these expensive data loggers are not able to directly transmit sensor data to the internet in real time but rely on manual download on the site.

This problem can be solved by our BoSL microcontrollers. BoSL microcontrollers is capable of controlling and reading the high-end commercial sensors, as well as sending the data to the internet after each sensor reading, without the need of a separate data logger.

This wiki page introduces how BoSL microcontroller functions as an IoT-enabled data logger for the high-end commercial sensors, using BoSL Board, and Greenspan Water Depth Sensor (PS-7000A) and Turbidity Sensor (TS-1000A) as an example.

Hardware

Both PS-7000A and TS-1000A are analogue sensors with 4-20mA signal current output, but the PS-7000A is a 2-Wire Loop Powered sensor while TS-1000A is a 4-Wire Fully Isolated sensor. This section aims to provide instructions on how to wire up these two kinds of sensors.

In addition to the BoSL Board, signal relays (with low coil voltage) and resistors are required to control both sensors and help to read the sensor measurement. One BoSL Board can be used to connect to both sensors if they are installed at the same location.

TS-1000A Turbidity Sensor (4-Wire Fully Isolated)

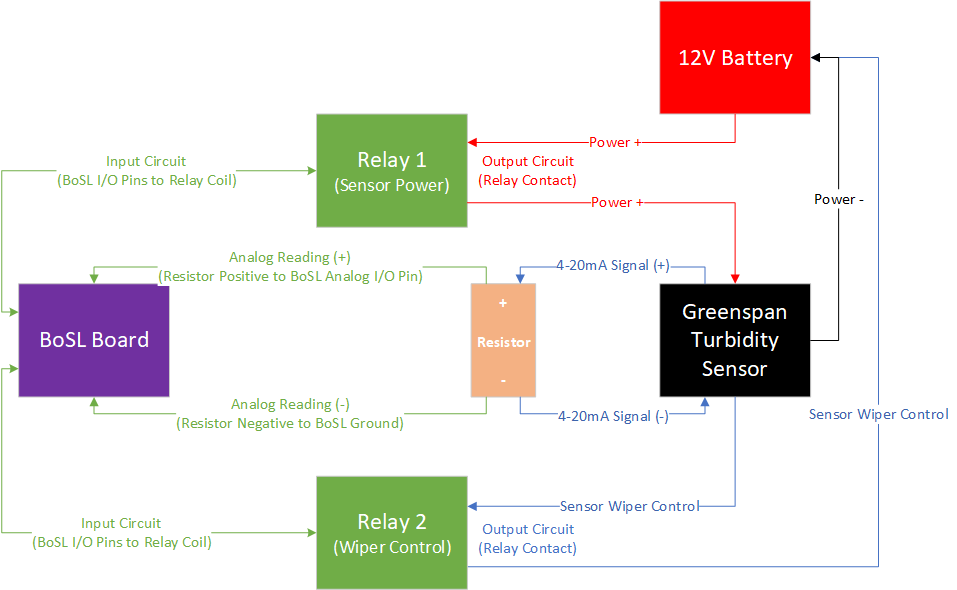

4-Wire Fully Isolated sensor use independent 4-20mA signal cables (+ive and -ive) and power cables (+ive and -ive). The following figure shows the relationships between each component.

In this case of turbidity sensor, two relays are used as the switches. One relay is used to switch on/off the power for the commercial sensor, and the other replay is used to trigger the wiper to clean the sensor lens. The output circuits are open by default, and they can be opened/closed by the sending input signals from the BoSL I/O pins. Two I/O pins on the BoSL Board are needed to control one relay. Since the relays are low-voltage latching relays, they require no continuous power consumption but a signal pulse.

To read the sensor measurement after switching on the sensor, a resistor is connected to the positive and negative 4-20mA signal cables in series. A 100-ohm resistor would convert the signal to 0.4-2 volts of voltage across its two terminals, which can be read by BoSL Board using the analog reading function.

The following tables and figure show how exactly everything is wired up in the hardware setup. In application, a PCB breadboard is used with relays, resistor, and screw terminals soldered on it. We call it interface board and it makes the installation and maintenance work in the field easier.