Turbidity Sensor

12th November 2019

So we finally made some nice progress with the Turbidity Sensor design.

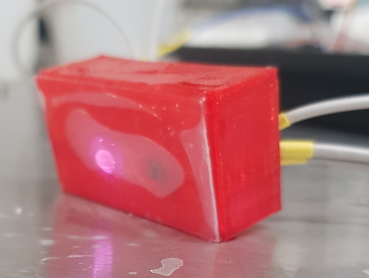

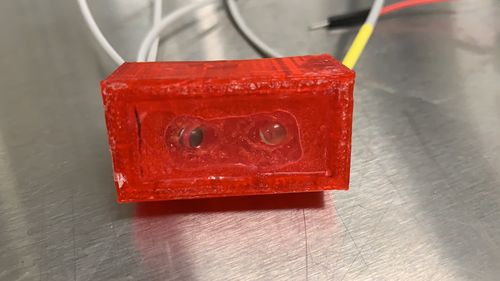

First step was to print our case using our 3D printer. Here it is:

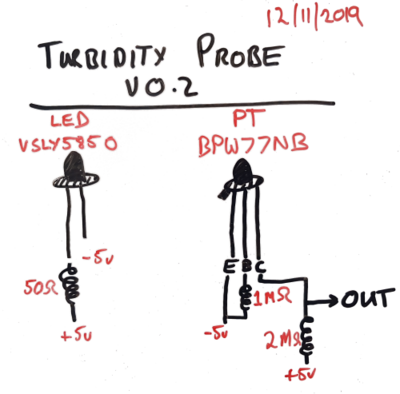

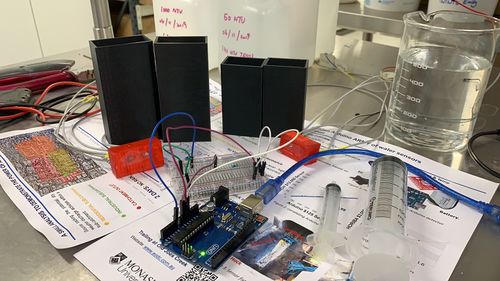

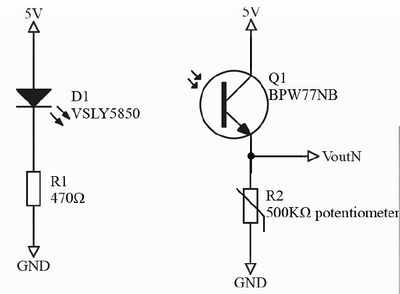

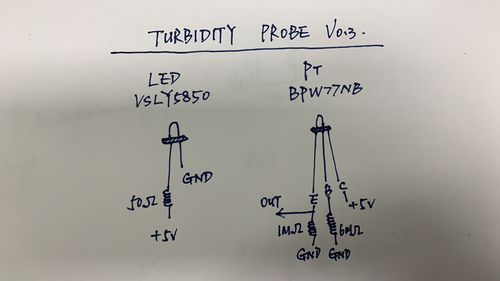

Next step was to test out some hardware for the little guy. We bought two main things: (1) a LED that puts out 850nm wavelength and (2) a phototransistor. The details of the connection we used is here:

We also needed some resistors in the circuit, a 5v power supply and something to read the output (obviously, we used an Arduino)

Next step, put it all together and see if it works! So, we used some epoxy and wired this all up to make this sensor:

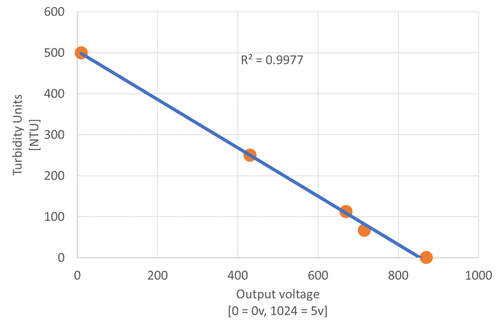

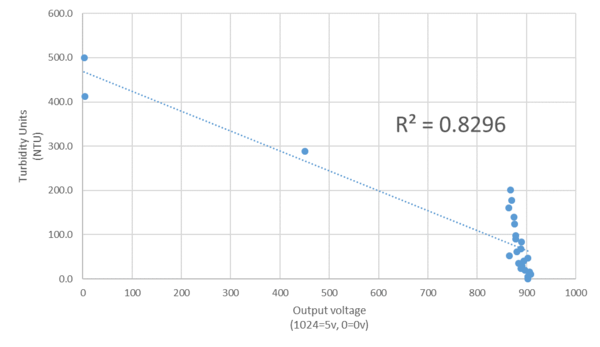

Next step, test the little bugger. We did this using turbidity solutions and a deep cylinder (at least 100mm deep). We tested five turbidity solutions ranging from 500 NTU to 1NTU (tap water). Here are the results we got:

So, in conclusion, we are rather happy with the workings of this cheap turbidity sensor. It costs less than $5 AUD in components, and a little time to put together. The only issue is that the range of the sensor is really limited to just 0 to 500NTU; anything higher and we think we will need to include a photo-diode alongside the phototransistor to get those big NTU values. Also, we are concerned with the energy use that this little puppy dog may take up - the resistors are even heating up (NOT A GOOD SIGN!). The last thing we want to fix is to make this all run on 3.3v instead of 5v...our BoSL board is a 3.3 volt machine, so we want to keep that consistent. Finally (I know, I said the last thing was the final, but this will be) we need to continue to develop our turbidity wiping mechanism...turbidity probes need to be cleaned a lot, so a good wiper is essential or readings are lets just say poor...

Over and out for today.

13th November 2019

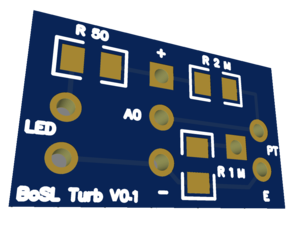

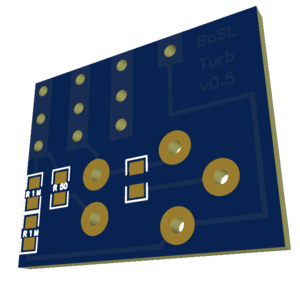

So, today we began making our circuitry for the new turbidity sensor. It is looking good, but when we tried to print the board on our new PCB printer, the ink was all dried up! Come on Voltera, please send us the new ink so we can start printing our boards again! Here is an image of the circuit we made today in an easy to use program called EasyEDA.

17th November 2019

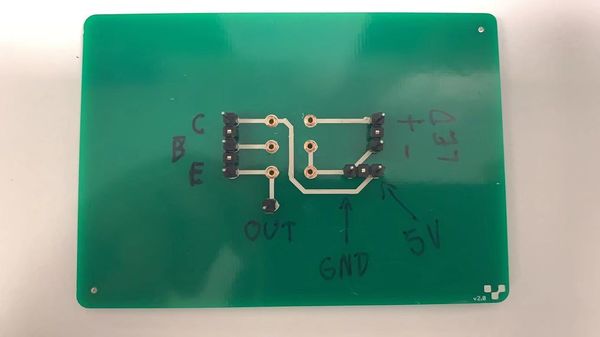

We have begun designing our wiping device, but to do so we needed to revamp our circuit to allow for some motors to drive the wiping action. We began printing many different versions of the above board on our Voltera printer (thanks Voltera for finally giving us our consumables), but there were a hole bunch of issues...including that the holes and pads were not optimised for our Voltera. So, we spent the day designing a new circuit that now looks like...

More to come from Miao in the next few days...

19th November 2019

This is Miao's turn for updating the process.

Based on Dave's experience, we started to do the calibration of the sensor.

Now we don't want to use a deep cylinder for testing, as the glass cylinder is transparent, we designed a black box and printed it by our 3D printer. The box is designed to fit our sensor and it is 100% infill.

Also, Dave printed another sensor case, which is smaller than the previous one and it has bulgy edges, so it is easier to glue epoxy on the surface of the LED and PT.

So now we have two sensors, the big one which Dave used for testing and a small one with bulgy edges.

After we wired the LED and PT for the small sensor, we tested that, it works and the analog read is more than 400 in air. However, when we cover the epoxy piece on the surface, the reading number became 0 or a quite small number(less than 10). That's weird. We need to wait until the glue drys and then we will test it in water to see if it has any difference.

To be continued……

20th Novermber 2019

The glue of the sensors is dry and we put the sensor in water in the black box, the reading number changed to around 920, and when we get it out in the air, the number changed to 12.

Anyway, as it can be used for testing in water, we started dosing the solution for testing.

We use DI water(0.18NTU) and another lab solution(807NTU) to make the solution, we change the testing solution's turbidity by adding more 807NTU solution into DI water and then record the analog reading.

Solution with different turbidity was tested, the range is between 0.18 and 807, from 0.18 to 50 NTU, the step is 5NTU, and the step changes to 10NTU for solution between 50-100NTU, from 100-200NTU, the step is 20 NTU, and from 200-1000NTU solution, the step is 100. Both the big sensor and small sensor are tested.

The results can be seen in the following diagram.

From the data, it can be seen the results is different from Dave's result. From 0.17 to 50NTU, the analog readings are floating and do not have too much change, and from 60 to 300NTU, the outputs decrease in a narrow range, after that the reading number suddenly changed to a very small number. We also found, for both sensors, the output fits a straight line most between 60 to 200NTU.

The difference between my results and Dave's maybe the container of the solution is the black box.

To be continued……

21th Novermber 2019

As the results of the small sensor and the large sensor are different, we tested the two sensors to compare them.

We put both sensors in air, the analog reading of both sensors is about 12. However, when we put the small sensor in a black box(just in the air without touching water), the reading is also around 12, and after touching water, the number changed to around 926. For the big sensor, when put it in the black box without touching water, the reading is around 800, and if it touches water, it becomes 926.

I think the large sensor's results are more make sense, as the results in air and in DI water do not have a large difference.

But, why the two sensors perform so different when staying in the black box without water? Another question is why readings become different after touching water?

For the first question, we guess the reason may be the distance between the epoxy and the LED and PT, or maybe the bulgy edges? Now we know that base on our setting, LED and PT are very sensitive about the distance between the epoxy cover and their surface. More work needs to do to figure out these problems.

To be continued……

23th Novermber 2019

Today we did two things:

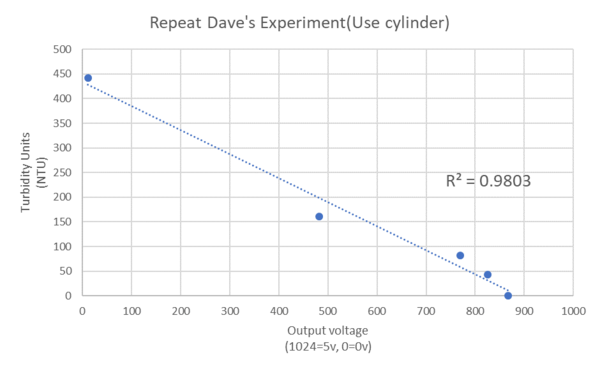

1. We repeated Dave's experiment(use the big sensor to do the experiment in a cylinder), 2. Recalibration(use the big sensor for testing, more accurate as we use the real sensor to test the turbidity of each solution)

For the first experiment, we got a similar trend but a different result.

I think the reason we got a different result is that we cannot make all the configuration of the environment exactly as same as before, and the sensor is very sensitive to the configuration(the distance between the epoxy and PT) and the surrounding environment, as the epoxy we glued to the sensor case has changed, so it has a different result.

For the second experiment, we use the big sensor for recalibration, and all the solution are tested to double-check their turbidity before testing.

The results are different from the previous experiments.

The output results are between 860 to 900 for the solution between 0 to 200NTU, and the analog output keeps floating, it does not have a specific trend. Therefore, it is not easy to calibrate the result with an equation.

Another problem is when we get the analog reading for each solution, the reading numbers always have a floating vibration, I think it is a problem of the circuit.

Now the setting of our sensor reports different results in the same configuration, so it is difficult to duplicate the past experiment. We are thinking to change the setting of our sensor(change the resistor or change the sensor case or add some parts)…………

Need to search for more information for our development……

27th November 2019

As we still cannot get satisfactory results, we want to start to repeat the experiment on the paper, and see if we can get the similar result, then we will find the difference between their settings and our design, then figure out the problem.

We did not get the exact same Acrylic tube, so we use the Vinyl tube with inner diameter 19mm to instead, and then we use our 3D printer to print a house of the sensor. The house can hold the tube in the center, and set LED on the top of the house and the PT on the side, LED and the PT is perpendicular to each other.

After that, we use the Clear Liquid Epoxy to glue the tube, LED and the phototransistor to the case, the Liquid Epoxy is fully waterproofed and 100% transparent. Now waiting for it dry and test it tomorrow……

28th November 2019

We do use the new sensor box for testing, the circuit is showed as following:

However, the resistor we use has changed, R1 is changed to 500ohm and R2 is 330k ohm. The results do not change too much as the solution changes. We have to change the circuit.

The first thing we want to change is connecting the base to the ground. We think the base may perform as an amplifier, and it may affect the analogue reading of our sensor. To compare with the previous test, we increase the resistance of the base, so the resistor is changed to 6M ohm. Another thing is that we want to make the LED brighter, so we change the resistor connecting to the LED as 50ohm. Therefore, the circuit is like:

We put the new black sensor in the glass cylinder for testing, for accuracy, we test the turbidity of each solution before the test.

Then we got the result, it looks pretty much better than before:

Now we sure that the resistor on the base has the critical effects, and we changed the resistor even larger(10M ohm), but the result is not as good as 6M ohm, as the reading in 1000NTU solution is about 1000, that's good, but the reading in air and in DI water is not 0, that's not what we want, so we need to try to find an optimal resistor later.

As we think we have found the critical factor, we just use the 6M ohm resistor on the base and then use the circuit to test the previous sensor(red one with a piece of epoxy on the surface), we still put the red sensor in the black box, just as same as before, see the result:

Although the result is better than before, some results are still unreasonable, this means we still got some problem with our design, now we are thinking about how to change our sensor case and design. Also, the floating vibration problem still exists, we are planning to use our PCB printer to get a better board to get rid of this problem.

To be continued……

29th November 2019

As we still want to use the wiper, so the black sensor case we used yesterday should be changed. We are wondering if half of the case can still work. Therefore, we use our 3D printer to print half of our case which is a triangular case. We also use the Liquid Epoxy to glue tube on the case, both the whole tube and half tube are used for testing. The settings are shown as below:

Just waiting for the Epoxy dry.

Also, our new board is printed out by our PCB printer, just waiting for the sensor ready and then test them.