Rain gauge

This section shows the journey for making our 3D print rain gauge!

Contents

Design journey

We didn't start from scratch - we work on Suromark's version (referred as original design in the following) and we did some changes to that:

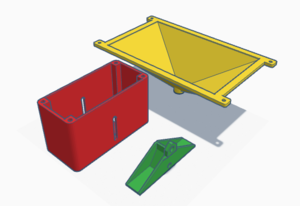

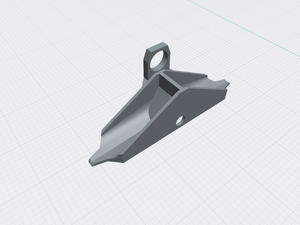

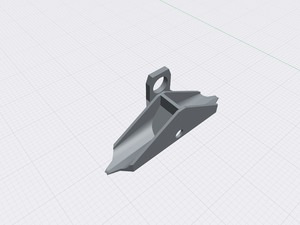

First, we noticed that the tipping bucket can get stuck to the pivot if operated overnight, so we changed the flipper with 0.6 mm clearance. Secondly, we noticed that not all of the water in the bucket can escape when tipping. We compared with the standard tipping bucket rain gauge design, and we added a sharp edge and made some "swale" in the bucket to help divert water when tipping:

Thirdly, we found water can be soaked into the tipping bucket during long-time operation so we changed the 3D print from 30% infill to 100% infill;

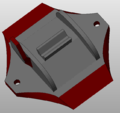

In the end, we found that the tipping volume can change from time to time. We found during the overnight operation, a small amount of water from splashing or dripping can stay on the rain gauge base, which probably increases the friction between the base and bucket, therefore influencing the tipping volume. In that case, we changed the base design - to make water can easily escape so the tipping volume is consistent.

3D print files

Thanks Stephen for designing and editing the files!

Nano Board code

Thanks Luke(Baiqian) Shi for the coding :)

File:Nano Rainguage Sender.ino

Assembly instructions

The following video outlines the process required to assemble the gauge and to connect it to a logging system.

Application

We have used these rain gauges in Xixi Shi's lab-wetlands to monitor the outflow rate. There are 6 wetlands in total, and we have equipped each wetland outlet with a rain gauge to monitor the outflow rate.

This is the calibration for each rain gauge tipping bucket:

| Rain gauge tipping volume(ml) | Feb 16 3pm | Feb 17 11am | overnight difference (%) |

|---|---|---|---|

| R1 | 2.8 | 2.8 | 2 |

| R2 | 2.9 | 2.9 | 2 |

| R3 | 2.8 | 3.1 | 9 |

| R4 | 2.9 | 3.1 | 7 |

| R5 | 3 | 3 | -1 |

| R6 | 3 | 2.9 | 2 |

New Design journey

Our design is based on the Giovanni Aggiustatutto's version. We made some changes to it:

Firstly, we noticed that this tipping bucket had the same issue as Xixi's design, which was that water could not escape when tipping. To address this, we added a sharp edge and slope trench to help the water escape while tipping.

Secondly, based on Xixi Shi's experience, we found that the PLA filament absorbs water in a humid environment, which can alter the flipper's weight and tipping value. Therefore, we decided to use other waterproof materials such as PETG and PP filament to print the flipper.

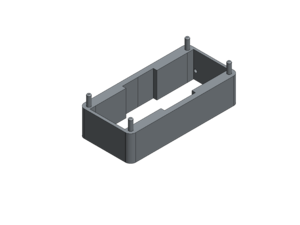

Thirdly, we added a base at the bottom of the rain gauge container to ensure that rainwater can escape better after tipping.

Flipper (tipping bucket)

We made several versions of changes to the sharp edges and slopes to improve water drainage.

Stand

We added an stand under the base container to raise the height without using threaded rod.

Additionally, we removed the flat aluminum profile that Giovanni used under the container and added four arms to the stand, which connect the funnel and rain gauge box using M5 stainless steel stranded rods.

Testing

Printing material

We used PLA and PETG to print the flipper and test its waterproof effect. First, we measured thier dry weight and put them in the water overnight and then measured the wet weight separately.

Coding

As the Arduino only allows one program running at a time, in the case of flip happened during the uploading process, an additional MicroBoard is used as an counter to help solve this issue. The connection is shown as follow:

The code is attached here:

File:Newdesign Rainguage Sender.txt