Difference between revisions of "Air Sensor"

| Line 37: | Line 37: | ||

==12 July 2021== | ==12 July 2021== | ||

Initial testing with the sensor started, The sensor are exposed to ambient air for the initial test.. From the data the reading from the T6713 sensor is a bit higher compared to the k30 which might suggest it need some calibration done. | Initial testing with the sensor started, The sensor are exposed to ambient air for the initial test.. From the data the reading from the T6713 sensor is a bit higher compared to the k30 which might suggest it need some calibration done. | ||

| − | [[File:CO2 Sensor result 12072021.png| | + | |

| + | [[File:CO2 Sensor result 12072021.png|400px|CO2 Sensor result]] | ||

==17 October 2022== | ==17 October 2022== | ||

Revision as of 03:35, 18 November 2022

Contents

16th September 2020

This series of ongoing updates pertains information regarding the development of a low-cost real-time air quality sensor (AQS).

At the beginning of this project, we utilized various low-cost sensors to measure the concentration of contaminants present in the air. This included carbon monoxide (CO), nitrogen dioxide (NO2), ozone (O3) and sulfur dioxide (SO2), concentration of particulates below 2.5μm (PM2.5) and particulates below 10μm (PM10) as well as the temperature, pressure and humidity of the air.

Plantower PMS5003

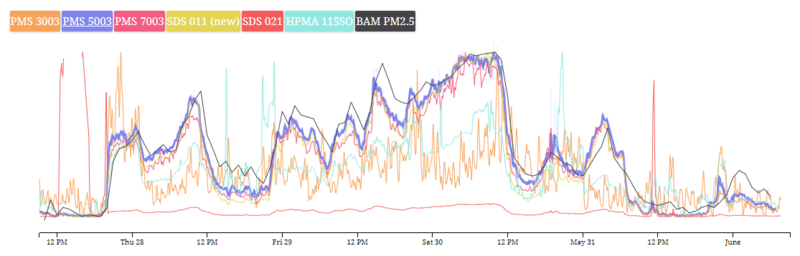

The sensor is a 5th generation of PMS sensors developed by Plantower of whom are a leading manufacturer in the development of low-cost particulate sensors. They operate via the laser scattering principle, which has been proven to be the most robust technique for an accurate and precise particulate concentration reading. A test from The World Air Quality Project team demonstrated that the PMS5003 was one of the best sensors for measuring particulate concentration, with readings closely resembling that of the industry standard BAM PM2.5 measurements.

During one of our own tests conducted is proximity to the an air quality sensing station at Box Hill, Victoria demonstrated that the readings were reasonably precise, with the PM2.5 recording between zero and two, and the PM10 recording between zero and three. At these times, the Box Hill monitoring station recorded readings of nine for the PM2.5 and five for the PM10. The difference in the data obtained will most likely be due to the different sensing locations, that is, the AQI sensor is installed in a more populated area with a greater number of vehicles in close proximity, whereas the BoSL sensor was in a more suburban area with less pollution sources nearby.

I'll add info for the rest of the sensors soon!

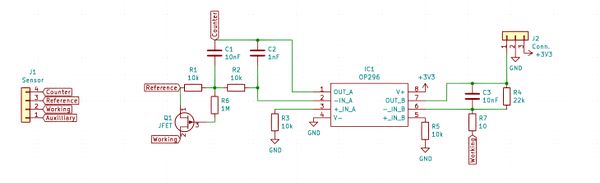

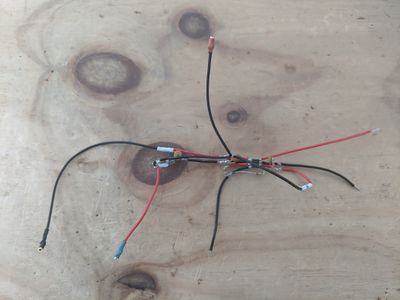

BoSL team decided it best to experiment with some industry grade gas sensors. The chosen sensors were the alphasense B series sensors for CO, NO2, O3 and SO2. The following potentiostatic circuit was constructed to test the sensors. The design was based off a style of circuit recommended by alphasense in their application notes and implemented with a OP296 dual operational amplifier. This circuit was then constructed to test before being manufactured.

The CO electrochemical gas sensor was then tested. From start up, the sensor begun measuring the analog reading from the CO sensor, registering an analog reading of ~80 that oscillated in the shape of a sin wave. After about a minute, the readings began to fall dramatically until the reading was ~10, then the fall slowed and after a few more minutes the readings reached zero and did not rise again. As a second test, the SO2 sensor was tested and stayed at a constant analog reading of ~60 for numerous minutes. As another test the SO2 sensor was placed behind a car exhaust as it started (highest concentration of SO2 during the startup of the engine, otherwise a negligible proportion of SO2 in the exhaust), this prompted a rise in the readings to ~90 for a period of ~ 10 seconds before the readings read normal again. Upon starting the engine again, the readings did not rise, however this may be due to the engine already being warm. Thus, it cannot be said for certain that the readings rose out of coincidence or actually from the readings, and unfortunately there are not a surplus of safe methods to produce a known amount of SO2 through a chemical reaction of otherwise.

Carbon Dioxide Sensor

This part of the page will focus on the testing of carbon dioxide gas sensor. There are two types of sensors that being tested which are : - Telaire T6713 - Senseair K30

The K30 model is the more popular model that are already used in multiple field deployment while the T6713 are chosen due to its miniature size and smaller power requirement compared to the K30.

12 July 2021

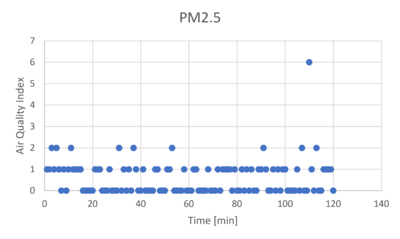

Initial testing with the sensor started, The sensor are exposed to ambient air for the initial test.. From the data the reading from the T6713 sensor is a bit higher compared to the k30 which might suggest it need some calibration done.

17 October 2022

For testing the sensors, we need to create a gas chamber to contain the type of gas that are detected by the sensor and at a certain ppm value. We use a 1 liter lunch box as our container and attached connector to it.

10 November 2022

Turns out the connector that we use is not ideal for the testing as the tubing that the lab used are not ideal for the chamber design as it does not have any method to close the connector when it is not connected to any tubing. To troubleshoot this problem, we used an existing gas bag connector and replaced it in our mini chamber which composed of a push/pull valve and a septum fitting.

15 November 2022

Just found the correct method to force the T6713 into calibration mode, from the manual there's a need to calculate the CRC value. The CRC method that the sensor accepted is the modbus CRC-16 or (Serial 8E1). As it turns out if the sensors just returning 0 after we sending the command, most likely its just didnt recognise the CRC as the correct value.

17 November 2022

We do a testing on two standard level of gas 600 ppm and 2000 ppm. The method that we used is by putting the gas into the chamber while leaving the outlet valve open for a few seconds. and then we closed the chamber while leaving the sensor to log for a view minutes. The data from this two initial value returns us that the T6713 sensors always overshoot the actual ppm value of the gas. This might due to placement issues of the sensor which is quite close to the inlet and may have all of the CO2 gas entrapped inside the sensor causing a bias in reading or the sensor is just not as accurate as the K30. Further testing are required to determine whether the T6713 are usable. Start testing with standard gas to the chamber