Difference between revisions of "FlowMeter v1"

| Line 1: | Line 1: | ||

A flowmeter is required to find the volume flowrate of water travelling through a thin hose. The application requires a very small flowrate to be precisely monitored over an extended period. To ensure that a commercially available flowmeter will satisfy these criteria, two different flowmeters were experimented with, and calibration curves were attempted to be found. | A flowmeter is required to find the volume flowrate of water travelling through a thin hose. The application requires a very small flowrate to be precisely monitored over an extended period. To ensure that a commercially available flowmeter will satisfy these criteria, two different flowmeters were experimented with, and calibration curves were attempted to be found. | ||

| − | A sample code can be downloaded from here: [[File:Flowmeter.ino|thumb|Sample code of uploading flow readings to a web cloud]] | + | A sample code can be downloaded from here: [[File:Flowmeter.ino|thumb|Sample code of uploading flow readings to a web cloud]] (Notes: compatible with BoSL version 0.4 and above only) |

Revision as of 23:51, 3 January 2021

A flowmeter is required to find the volume flowrate of water travelling through a thin hose. The application requires a very small flowrate to be precisely monitored over an extended period. To ensure that a commercially available flowmeter will satisfy these criteria, two different flowmeters were experimented with, and calibration curves were attempted to be found.

A sample code can be downloaded from here: File:Flowmeter.ino (Notes: compatible with BoSL version 0.4 and above only)

The Initial Setup

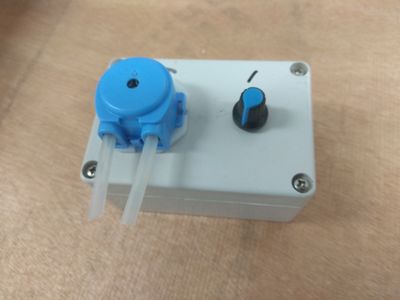

The first setup involved the pump and flowmeter pictured below.

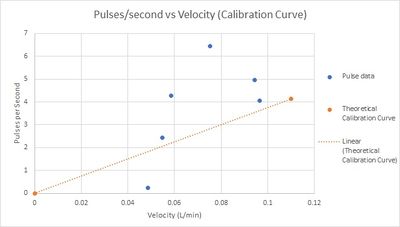

The pump fed water through the flowmeter into a measuring cylinder over some time, and the final volume in the measuring cylinder was used to find the volume flowrate. The knob on the pump varies its velocity, so this procedure was repeated for a range of pump flowrates. According to its datasheet, the flowmeter outputs pulses with a frequency that directly correlate with the volume flowrate. The minimum rating for the flowmeter is 0.3L/min for the calibration curve to be a straight line, but it was hoped that the required range of flowrates (0.01L/min to 0.15L/min) could be extrapolated through a non-linear calibration curve for lower frequency pulses. Unfortunately, the flowmeter proved to be quite unreliable for low flowrates. For particular flowrates, the flowmeter consistently output a larger frequency for a lower flowrate.

As can be seen, the calibration curve is not strictly increasing, and therefore this flowmeter is not ideal for this application.

An Alternative Setup

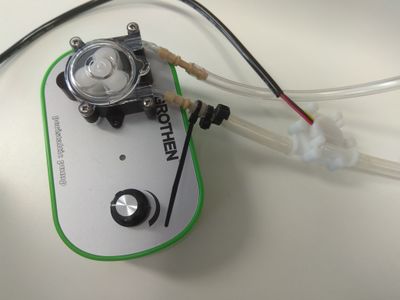

A different flowmeter and pump were used for another trial. These are pictured below.

The new flowmeter is rated for a minimum flowrate of 0.15L/min. Above this flowrate, the frequency of pulses should linearly correlate with the volume flowrate. Again, it is hoped that the calibration curve for flowrates lower than 0.15L/min will produce some kind of calibration curve which allows the volume flowrate to be found. The new pump also has a wider range of speeds, which will allow for better testing of the flowmeter.

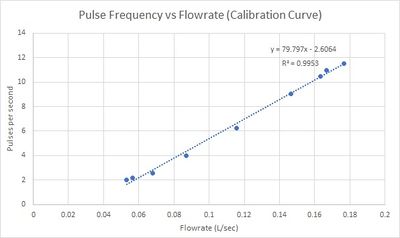

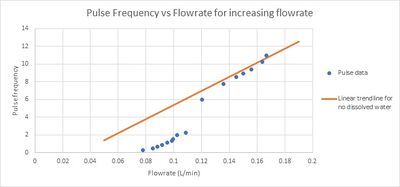

After a series of tests, a calibration curve was found for the flowmeter.

The line of best fit shows that there is a good linear relationship between pulse frequency and flowrate. The uncertainty in the trendline appears to be quite small. This calibration curve, however, relies on there being no air trapped inside the flowmeter. During testing, air trapped inside the flowmeter gave fluctuating and unpredictable results; the more air is trapped in the flowmeter the lower the output pulse frequency. This effect is quite significant for small flowrates (~0.08L/min), but increasing the flowrate past around 0.15L/min appears to force most of the air trapped in the flowmeter out (this may be the reason that the flowmeter has a minimum flowrate rating of 0.15L/min). To ensure that all the air was removed, rotating the flowmeter and tapping it also helped force air out. In the following ‘calibration curve’, the water velocity was initially set to a very low value, and then slowly increased. This slowly forced out air that had been trapped inside the flowmeter. As expected, the pulse frequency is much too low to begin with as there is a lot of air trapped inside the flowmeter, and as air is forced out, the data approaches the linear trendline for no air trapped inside flowmeter

As such, these results indicate that if there is no air bubbles in the water being pumped through the flowmeter, then the flowmeter can work reliably for small flowrates and should therefore be ideal for this application. Caution must however be taken to flush all air out of the flowmeter during installation. To ensure that this flowmeter is appropriate, trials of the flowmeter’s reliability may need to be taken for the actual conditions that the flowmeter will be operating in, to ensure that air does not get trapped in the flowmeter over time, and no other similar issues occur.