Difference between revisions of "PCB Prototyping"

(Created page with "Here we will document various ways of prototyping PCB's == 22 June 2020 == A common PCB manufacturing method of toner transfer was tested. Here a laser printer is used to pl...") |

|||

| Line 9: | Line 9: | ||

<gallery> | <gallery> | ||

File:PCB mask.jpg|Copper PCB blank with toner solder mask | File:PCB mask.jpg|Copper PCB blank with toner solder mask | ||

| + | </gallery> | ||

| + | |||

| + | Below is the result after etching and removing the toner. Evidently, | ||

| + | |||

| + | |||

| + | <gallery> | ||

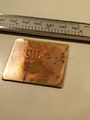

| + | File:PCB etch.jpg |Copper PCB after etching | ||

</gallery> | </gallery> | ||

Revision as of 10:28, 22 July 2020

Here we will document various ways of prototyping PCB's

22 June 2020

A common PCB manufacturing method of toner transfer was tested. Here a laser printer is used to place toner on photo-paper of the PCB. This is then ironed to a cleaned copper PCB blank. In water, the photo-paper can be removed leaving only the toner which can act as an etching mask.

A copy of the Velocity PCB was transferred to a copper PCB blank using this method. The result is shown in the image below. As can be seen the transfer process was not perfect, (and the masked area is the negative of what it should be) however the areas which did stick stuck quite well. Scratching with a fingernail does not remove the coating.

Below is the result after etching and removing the toner. Evidently,