Difference between revisions of "PCB Prototyping"

| Line 11: | Line 11: | ||

</gallery> | </gallery> | ||

| − | Below is the result after etching and removing the toner. Evidently, | + | Below is the result after etching and removing the toner. Evidently, the circuit was etched for too long and the masked areas over expanded to remove some of the finer detail. Despite this the process worked surprisingly well for a first attempt. It is thought that better results could be achieved with finer tuning of the technique. |

Revision as of 10:31, 22 July 2020

Here we will document various ways of prototyping PCB's

22 June 2020

A common PCB manufacturing method of toner transfer was tested. Here a laser printer is used to place toner on photo-paper of the PCB. This is then ironed to a cleaned copper PCB blank. In water, the photo-paper can be removed leaving only the toner which can act as an etching mask.

A copy of the Velocity PCB was transferred to a copper PCB blank using this method. The result is shown in the image below. As can be seen the transfer process was not perfect, (and the masked area is the negative of what it should be) however the areas which did stick stuck quite well. Scratching with a fingernail does not remove the coating.

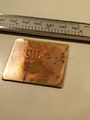

Below is the result after etching and removing the toner. Evidently, the circuit was etched for too long and the masked areas over expanded to remove some of the finer detail. Despite this the process worked surprisingly well for a first attempt. It is thought that better results could be achieved with finer tuning of the technique.