Difference between revisions of "In Water Vel Sensor"

| (85 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

<b> This section documented our journey to develop a low-cost water velocity sensor based on doppler effect!</b> | <b> This section documented our journey to develop a low-cost water velocity sensor based on doppler effect!</b> | ||

| + | |||

| + | Check out the full paper!: [https://doi.org/10.3390/s22197451 https://doi.org/10.3390/s22197451] | ||

For information on specific velocity sensors see: [[BoSL Velocity Database]] | For information on specific velocity sensors see: [[BoSL Velocity Database]] | ||

| Line 1,144: | Line 1,146: | ||

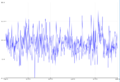

File:Velocity 8 plot.png|Week 4 velocity data velocity vs time plot, y-axis velocity (mm/s), orange hach, blue bosl, colour of bosl indicates signal strength of point (blue strong- white weak) | File:Velocity 8 plot.png|Week 4 velocity data velocity vs time plot, y-axis velocity (mm/s), orange hach, blue bosl, colour of bosl indicates signal strength of point (blue strong- white weak) | ||

</gallery> | </gallery> | ||

| + | |||

| + | The plots show that this algorithm can be used quite effectively to measure the flow velocity. Particularity also useful is that the sporadically high measurements appear as having a much lower signal strength, meaning that they can be effectively filtered out. | ||

| + | |||

| + | == 27th August 2020 == | ||

| + | |||

| + | The refinement of the 3d printed case from 8th August was tested. The initial indications were positive. Much less leakage of the Gell-Gum occurred as had with previous designs. The design looks water tight, however particularly with the lack of cable grommet, this needs to be tested further, and for a longer duration. | ||

| + | |||

| + | == 8th September 2020 == | ||

| + | |||

| + | New data was received from the velocity sensor. This was compared against the hach probe. The data was less robust than usual, as the velocities which are greater than 200 mm/s generally had given stronger readings, however this was not the case for this data set for some of the rainfall events. | ||

| + | |||

| + | The below plots are the week 4 and 5 data with the algorithm tweaked slightly to increase threshold and introduced a filtering on low amplitude data. | ||

| + | <gallery> | ||

| + | File:Vel filt algo 1.png | Week 4 velocity data velocity vs time plot, y-axis velocity (mm/s), orange hach, blue bosl, colour of bosl indicates signal strength of point (blue strong- white weak) | ||

| + | File:Vel filt algo 2.png | Week 5 velocity data velocity vs time plot, y-axis velocity (mm/s), orange hach, blue bosl, colour of bosl indicates signal strength of point (blue strong- white weak) | ||

| + | File:Vel filt algo corr.png|Week 5 velocity data calibraiton, y axis hach (mm/s), x axis bosl (mm/s) red line 1:1, colour of indicates signal strength of point (blue strong- white weak) | ||

| + | </gallery> | ||

| + | The changes can be seen to minimally impact the data from week 4 while addressing some issues with the week 5 data. The main issue seen to be caused by the algorithm changes are the of the minimum measurement velocity of about 150 mm/s. This change was not unintentional as it was found by looking at the FFT of the data that below this noise was seen in very great amounts and made it so that no real velocity data was present here. | ||

| + | |||

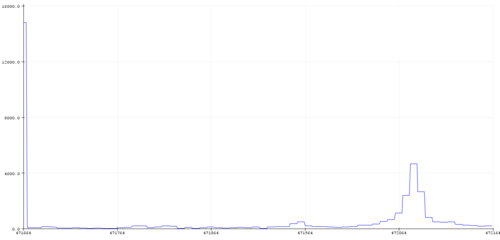

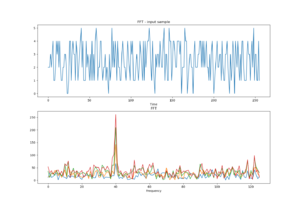

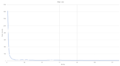

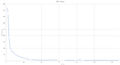

| + | This is shown below, with the old algorithm the peak at the low velocities would have been taken as the predominant peak for the velocity. This low velocity peak however is commonly seen in some FFT's regardless of the water velocity, so it was assumed that this should be not taken as part of the water velocity calculation. | ||

| + | This was especially problematic as if the low bin peak dropped below the threshold before the the true peak then the true peak would have been excluded from the velocity calulation. | ||

| + | |||

| + | To combat this three changes were made, the first was to check that if the peak was detected in the low velocity bins if there was another and perhaps slightly smaller peak at a higher velocity. If so this high velocity peak was chosen instead. This worked to alleviate most of the problem. However the minimum bin to check was also changed from bin 2 to bin 4 (causing the minimum measurable velocity to jump to 150 mm/s). Finally, the threshold was adjusted and optimized in light of these changes. | ||

| + | |||

| + | <gallery> | ||

| + | File:3384.0.png|FFT with noise in low velocity bins (black: hach) (red: new algorithm) | ||

| + | </gallery> | ||

| + | |||

| + | |||

| + | == 9th September 2020 == | ||

| + | |||

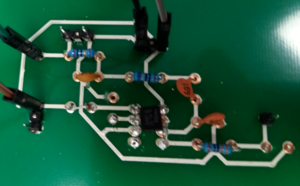

| + | 7 velocity sensors were build up. 6 of them had no issues however one of them presented a constant spike at about 3.5 m/s. This is similar to the issue seen in the field, however it is present without any transducers connecting. The issue look like a hardware/construction issue, as the PCB looks identical to all the others which did not have this issue. I think it would be good to write some testing code to screen for this at the manufacturing. | ||

| + | |||

| + | The velocity database has been updated [[BoSL_Velocity_Database]]. 2 PCB remain however I have run out of cable to make these into sensors. | ||

| + | |||

| + | == 10th September 2020 == | ||

| + | |||

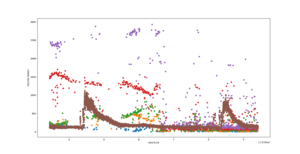

| + | Week 6 data was analysed today, the usual plots are shown below. The sensor is showing worse performance with the than in previous weeks. Notably many more points where spontaneous high readings are measured. This can be seen from about after August 31. It could be possible that something happened to the sensor at this time to change its characteristics or it could be that after this date new flow regimes were encountered that were not before. | ||

| + | |||

| + | <gallery> | ||

| + | File:Wk6 corr.png|Week 6 velocity data calibraiton, y axis hach (mm/s), x axis bosl (mm/s) red line 1:1, colour of indicates signal strength of point (blue strong- white weak) | ||

| + | File:Wk6 plt.png|Week 6 velocity data velocity vs time plot, y-axis velocity (mm/s), orange hach, blue bosl, colour of bosl indicates signal strength of point (blue strong- white weak) | ||

| + | </gallery> | ||

| + | |||

| + | == 11th September 2020 == | ||

| + | |||

| + | A production versions of the velocity sensor code with the above algorithm for detecting velocity was made. | ||

| + | |||

| + | It is a available here: [[File:Velocity Firmware rev 0.1.3.zip]] | ||

| + | |||

| + | == 16th September 2020== | ||

| + | |||

| + | The code on the velocity sensor here [[In_Water_Vel_Sensor_FFT_SD_Logging_Test]] was updated to [[File:Velocity Firmware rev 0.1.3.zip]] so the velocity reading could be taken directly from the automatic logging. | ||

| + | |||

| + | The data from the past week of logging was processed and the standard graphs are shown below: | ||

| + | |||

| + | <gallery> | ||

| + | File:Wk7 corr.png|Week 7 velocity data calibraiton, y axis hach (mm/s), x axis bosl (mm/s) red line 1:1, colour of indicates signal strength of point (blue strong- white weak) | ||

| + | File:Wk7 plt.png|Week 7 velocity data velocity vs time plot, y-axis velocity (mm/s), orange hach, blue bosl, colour of bosl indicates signal strength of point (blue strong- white weak) | ||

| + | File:Wk7 corr alt.png|Week 7 velocity data calibraiton, y axis hach (mm/s), x axis bosl (mm/s) red line 1:1, colour of indicates signal strength of point (blue strong- white weak) however the threshold for blue saturation is higher | ||

| + | </gallery> | ||

| + | |||

| + | As can be seen the plot shows a similar trend to the past weeks, the sensor performs well at high velocities, and less low at lower velocities generally tracking similarly to the hach probe. Notice that on the late end of the 2020-09-13 velocity event the BoSL probe declines in velocity measurement much faster than the hach. The hach always seems to have a similar smooth trailing off from rainfall events so perhaps this is an artifact of the some internal averaging method used. | ||

| + | |||

| + | The correlation plots show now much more data in the 500mm/s range. This data follows the linear trend-line indicating that the two sensors are measuring similar values. There is more data which occurs at low hach velocity but registers a high BoSL velocity. This appears to have a strong intensity (deep blue). The third plot plots the correlation again but with a higher threshold that is that points need a stronger intensity to be coloured deep blue. Here we see that these points at low hach velocity become much more lightly coloured that is that they can be distinguished from the points on the 1:1 line. This higher threshold does make the points at lower velocity very faint so this calls for a intensity threshold dependent measured velocity for effective filtering without throwing out good data unnecessarily. | ||

| + | |||

| + | == 17th September 2020 == | ||

| + | |||

| + | A seperate PSD was measured for each velocity sensor. This was done to assess the variance in the PSD's between the sensors. | ||

| + | |||

| + | To evaluate the PSD the velocity sensor was placed in a bucket of still water. The depth of the water was about 20 cm the sensor was placed facing downwards at a 5 cm depth. | ||

| + | The sensor was then set to print its RAW fft output to serial. This was recorded for about 250 samples and then the RMS of each bin was taken to find the PSD. | ||

| + | |||

| + | It was found that the positioning of the sensor in the bucket did not play a large role in determining the shape of the PSD for a particular sensor. | ||

| + | The sensors did vary quite considerably in their PSD, so it seem that getting a PSD for each individual sensor is necessary. I am thinking of uploading the PSD into the velocity sensor database so that it can be easily retried whenever needed. | ||

| + | |||

| + | == 4th October 2020 == | ||

| + | |||

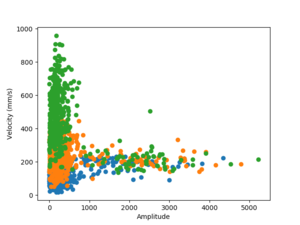

| + | A new velocity FFT analysis algorithm was tested. The method used in https://ieeexplore.ieee.org/document/9013073 was used, both uses boxcar averaging on the initial velocity spectrum and estimates the spectrum by find the FWHM. | ||

| + | A plot of the data under this algorithm is shown below. | ||

| + | <gallery> | ||

| + | File:Roman.png| Implementation of the algorithm as in described in the paper | ||

| + | File:Current.png| Current algorithm | ||

| + | File:Currentmaxamp.png|Current algorithm with new signal strength algorithm | ||

| + | File:Currentboxcar.png|Current algorithm with new signal strength algorithm and boxcar averaging | ||

| + | </gallery> | ||

| + | It is seen that the algorithm described in the paper produces worse velocity readings with higher deviation from the 1:1 correlation line when compared to the current algorithm. | ||

| + | 3rd image displays the current algorithm where the signal strength is taken as the the highest single bin. It is seen that this performs better is distinguishing the velocity points close to the 1:1 correlation line with a higher signal strength then those far away when compared to the current algorithm. The 4th images takes the algorithm and adds boxcar averaging as described in the paper. This performs similarly to the 3rd image however does have more high intensity points at 0 velocity and fewer near the 1:1 correlation. | ||

| + | It is hence chosen that the new signal strength algorithm will be incorporated into new version of the velocity sensor firmware. | ||

| + | |||

| + | |||

| + | For the velocity paper some statistical analysis is needed to determine the accuracy of the sensor. I think it makes most sense to do this analysis not over the entire range of the sensor but calculate an error for the ranges of the sensors operation, perhaps 20 mm/s intervals. | ||

| + | |||

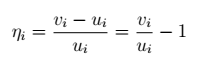

| + | The fractional error of the i-th velocity measurement is given by,<br> | ||

| + | [[File:Math.png|frameless]]<br> | ||

| + | Where v is the velocity as measured by the BoSL, and u the actual velocity. | ||

| + | The actual velocity determined by measurement of the flow with a hach probe. This comes with its own uncertainty Δu. | ||

| + | Thus, the uncertainty in η is,<br> | ||

| + | [[File:Math1.png|frameless]]<br> | ||

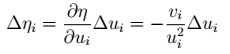

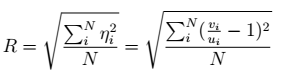

| + | We want to find the RMS fractional error over a number of points at similar velocities, hence taking the RMS of the fractional errors,<br> | ||

| + | [[File:Math2.png|frameless]]<br> | ||

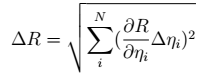

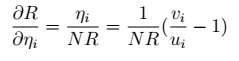

| + | To find the uncertainty in the RMS fractional error we have that $R$ is a function of η<sub>i</sub>, so the uncertainty is,<br> | ||

| + | [[File:Math3.png|frameless]]<br> | ||

| + | Note, <br> | ||

| + | [[File:Math4.png|frameless]]<br> | ||

| + | Thus substituting, <br> | ||

| + | [[File:Math8.jpg|frameless]]<br> | ||

| + | An expression for the uncertainty in the error. | ||

| + | |||

| + | For the Δu, the uncertainty in the hach velocity I have had some difficulty coming up with a reliable figure. The only source so far is [https://static1.squarespace.com/static/56fb56208a65e2ecc1316d3b/t/570f0e7fb6aa60320a39d6d1/1460604554173/AV9000ds.pdf Hach datasheet] which quotes a 1% error for the spectrum analyser and 2% for the doppler sensor. This is almost certainly a underestimate of the actual uncertainty as the figure is quoted for a uniform flow field. In the mean time the figure of a 3% uncertainty will be used until a better one can be found. | ||

| + | Running the above uncertainty calculation for the velocity data set of [[In_Water_Vel_Sensor_FFT_SD_Logging_Test]] from week 3 to week 8, with 200 mm/s bin sizes for the steps in hach velocity we get that | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! RMS (%) !! Mean erro (%) !! N !! u (mm/s) | ||

| + | |- | ||

| + | | 420 || 268 || 21973|| 0 - 200 | ||

| + | |- | ||

| + | | 141|| 40 || 4591 || 200 - 400 | ||

| + | |- | ||

| + | | 51 || -3 || 1758 || 400 - 600 | ||

| + | |- | ||

| + | | 34 || -14 || 1596 || 600 - 800 | ||

| + | |- | ||

| + | | 34 || -21 || 710 || 800 - 1000 | ||

| + | |- | ||

| + | | 37 || -29 || 48 || 1000 - 1200 | ||

| + | |- | ||

| + | | 69|| -62 || 12 || 1200 - 1400 | ||

| + | |- | ||

| + | | 62 || -55 || 6 || 1400 - 1600 | ||

| + | |- | ||

| + | | 81|| -79 || 7 || 1600 - 1800 | ||

| + | |- | ||

| + | | 73 || -69 || 6 || 1800 - 2000 | ||

| + | |} | ||

| + | The mean error was calculated by finding averaging the difference between the sensor measurement and the HACH measurement, then dividing the average by the center of the velocity range to get a relative figure. | ||

| + | |||

| + | |||

| + | It should be noted that the sensor is not designed to perform below 200 mm/s hence the high error, in practice these results could be filtered out using the point signal strength or the depth of the water. Above 1200 mm/s the error increases substantially again, however making definite conclusions about the error is difficulty as there are fewer than 10 data points. Additionally the hach probe occasionally read sporadically high, hence this may also be contributing to the high uncertainty. | ||

| + | |||

| + | == 10th October 2020 == | ||

| + | |||

| + | This weeks data is plot below: | ||

| + | |||

| + | <gallery> | ||

| + | File:Plotoct5.png | note hach velocity is now blue an the bosl organge, the darker the point the higher the amplitude | ||

| + | </gallery> | ||

| + | The sensor was cleaned during the battery replacement on the 29th of September | ||

| + | It is see that cleaning the sensor did not seem to help with the noise issues present, as erroneous high velocities are still being measured when water depths are low. Also at high velocities the sensor appears to consistently measure below the hach value. Other hypothesis include that the sensor's casing is not entirely waterproof and so there is some internal damage to the sensor. This would be easiest to test by destructively investigating the sensor. | ||

| + | |||

| + | We can also now plot the data for the ID008 sensor. | ||

| + | <gallery> | ||

| + | File:Plotoct5008.png|Plot of velocity readings for ID008 sensor | ||

| + | </gallery> | ||

| + | This seemed to have an issue of cutting out occasionally for multiple hours. The data however looks much cleaner than the other sensor, with many fewer sporadically high readings and greater similarity with the hach at higher lower velocities. | ||

| + | |||

| + | Deterioration of the sensor is seeming to play a significant role on the error of the sensor. If the RMS error calculation is run only on the week 3 data then, the results below are obtained, significantly less error than the entire dataset | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! RMS (%) !! ΔR (%) !! N !! u (mm/s) | ||

| + | |- | ||

| + | | 166 || || 4756 || 0 - 200 | ||

| + | |- | ||

| + | | 23 || || 235 || 200 - 400 | ||

| + | |- | ||

| + | | 29 || || 44 || 400 - 600 | ||

| + | |- | ||

| + | | 16 || || 394|| 600 - 800 | ||

| + | |- | ||

| + | | 17 || || 194|| 800 - 1000 | ||

| + | |- | ||

| + | | 34 || || 14 || 1000 - 1200 | ||

| + | |- | ||

| + | | || || 0 || 1200 - 1400 | ||

| + | |- | ||

| + | | || || 0 || 1400 - 1600 | ||

| + | |- | ||

| + | | || || 0 || 1600 - 1800 | ||

| + | |- | ||

| + | | || || 0 || 1800 - 2000 | ||

| + | |} | ||

| + | |||

| + | == 11th October 2020 == | ||

| + | |||

| + | Some issues were being had with the ID008 sensor in the field. It was not logging every minute and sometimes would go hours between logs. The SD card would not log either. I have reduced the BAUD rate on the BoSL- velocity line as hopefully this help in making this transmission more reliable. | ||

| + | |||

| + | Another idea has to see if the poor velocity readings of the sensor in field was to see if a re calibration could be conducted with the received data. To do this the PSD was taken from the FFT's September 16 to September 21. Here the velocity was low, the closest condition to still water in the data. This PSD was then used to rerun the velocity detection algorithm. | ||

| + | The results are below: | ||

| + | |||

| + | <gallery> | ||

| + | File:Sept recal.png | ||

| + | </gallery> | ||

| + | The sensor now appears to track the peaks better and generally perform better during flow events. The number of sporadically high velocity readings has decreased slightly however they still are common in the data. Additionally the sensor seems to not detect low flow events anymore that is that it rarely detects a point at low velocity. This is to be expected in hindsight as when we calibrate at this velocity, it causes the signal at that velocity to be interpreted as a null signal. This test does suggest that some re-calibration of the sensor would be useful. | ||

| + | |||

| + | == 18th October 2020 == | ||

| + | |||

| + | It was investigated to see whether the dirtiness of the sensor had anything to do with the the poor performance of the velocity sensor. Starting week 9 of [[In_Water_Vel_Sensor_FFT_SD_Logging_Test]] the 5K6 velocity sensor was cleaned and then placed back in the water. | ||

| + | |||

| + | The below are the usual time series graphs for before and after cleaning. | ||

| + | |||

| + | <gallery> | ||

| + | File:Old.png|before cleaning | ||

| + | File:Clean.png|after cleaning | ||

| + | </gallery> | ||

| + | The graphs do not tell have many significant differences. And it is difficult to tell if there has been an change in the quality of the sensor readings. This likely shows that the affect of the dirtiness of the sensor is a small factor in its overall performance. | ||

| + | |||

| + | For reference a photo of the sensor is provided below (its the 10K sensor but these were installed side by side for the same period of time): | ||

| + | |||

| + | <gallery> | ||

| + | File:Sensor clean.jpg | ||

| + | </gallery> | ||

| + | |||

| + | |||

| + | A test was going to be conducted on weather the sporadically high points were consecutive or sparely and uniformly distributed. As this would inform whether running measurement a couple of times until one of suitable amplitude was received is an effective technique to reduce this. | ||

| + | However current all the data is sporadically high, so this test will not tell much. However it can be said that the same sporadically high value is not achieved every measurement and this figure jumps around a lot. | ||

| + | |||

| + | Another issue diagnosed today was the velocity meters in the field logging only intermittently. | ||

| + | This seems to be an issue isolated to the hardware rev: 0.1.3. Whilst the exact issue was not able to be replicated, one which behaved similarly was. | ||

| + | The suspected cause was that the hardware rev 0.1.3 turns on a number of analog components when it takes a measurement. This causes a large current draw and over a long cable with considerable resistance, a voltage drop. This caused the velocity sensor to reset. | ||

| + | The issue was solved by modifying the firmware. Instead of turning on all components at once each component is turned on with a 20 ms delay. This spreads out the peak of the voltage drop and causes the velocity sensor to reset less. | ||

| + | It was also found that a large (470 μF) electrolytic capacitor place at the 3V3 - 5V converter help fix this problem. | ||

| + | |||

| + | |||

| + | == 29th October 2020 == | ||

| + | |||

| + | The 5K6 sensor used in the velocity testing is now back in the lab. It is currently undergoing tests, before a final deconstruction and investigation. The first test will be a PSD calibration in air, when the sensor is still dry. | ||

| + | The PSD which this resulted in did not show significant improvement when it was used to analyse the data. That is that many sporadic points still existed in it. | ||

| + | The sensor was then placed in water and the PSD calibration was done again. | ||

| + | When this PSD data was used, it was seen that the data did change, most of the sporadic points moved to higher velocitites | ||

| + | |||

| + | == 20th November 2020 == | ||

| + | |||

| + | Some changes were made the velocity algorithm and now it is working quite well. The falling edge detection algorithm was decided to be used as it produced the cleanest results. In addition this method was improved significantly by running the calculation on the natural log of the data. Some other smaller changes were made. The first was that the amplitude was calculated based on the height difference between the top and bottom of the peaks. The second was a method of reducing spontaneously high points. It was noticed that the edge detection algorithm would latch on to any edge of sufficient height even if it was more a 'bump' than a true edge of the transition between the high and low velocities. To attempt to filter these out, the regions before and after the 'bump' were compared in height if the height difference was not great enough then that edge would be ignored. The actual calculation of this was more technicality involved as it needed to be optimized to run on an ATmega328p. | ||

| + | This algorithm was seen to work well with the velocity distinguished and erroneous points having a small amplitude so they can effectively be filtered out. The algorithm did not work as well for smaller velocities below about 200 - 250 mm/s however it proved challenging to find a good way to extract this data, as it was often drowned in the 1/f noise of the of the low velocity bins. It was found the velocity measured by the falling edge algorithm was about 1.5 times higher than the HACH velocity however, it is hypothesized that this is due to the difference between the mean flow and the maximum speed of dispersed particles in the flow. | ||

| + | |||

| + | |||

| + | <gallery> | ||

| + | File:Velocity Edge Time.png|Velocity Edge Time plot, dark points have high amplitudes | ||

| + | File:Velocity Edge Correlation.png|Velocity Edge Correlation plot, dark points have high amplitude | ||

| + | </gallery> | ||

| + | |||

| + | Below is the data again with a crude filter in place. The filter is set to only filter the data with a low amplitude when the velocity is above 300 mm/s. This is because at velocities below 300 mm/s some of the data with a low amplitude is not noise but the actual flow measurement. | ||

| + | <gallery> | ||

| + | File:Velocity Edge Filter.png|Velocity Edge Filter, darker points have higher velocity | ||

| + | </gallery> | ||

| + | |||

| + | === Velocity Algorithm Description === | ||

| + | Below is a python psudo-code implementation of the velocity algorithm used for the results above | ||

| + | |||

| + | indx_low = 3 #start of fft bin range used | ||

| + | indx_high = 64 #end of fft bin range used<br> | ||

| + | max_bin = 0 #stores velocity bin of interest<br> | ||

| + | #whiten noise | ||

| + | fftpsd = [binn/weight for binn,weight in zip(fft, PSD)]<br> | ||

| + | #take natural log | ||

| + | fftpsd = [math.log(x) for x in fftpsd]<br> | ||

| + | #gausian blur velocity bins | ||

| + | fftpsd = gf(fftpsd, sigma = 2)<br> | ||

| + | #sobel derivative | ||

| + | sob = [-1, 0 ,1] | ||

| + | dfft = [] #array to store the derivative of the FFT array <br> | ||

| + | #calculate derivative of array | ||

| + | for i in range(len(fftpsd)): | ||

| + | try: | ||

| + | val = sum([x*y for x,y in zip(sob,fftpsd[i-1:i+2])]) | ||

| + | except IndexError: | ||

| + | val = 0 | ||

| + | dfft.append(val)<br> | ||

| + | ctlow = -0.35 #threshold for edge gradient | ||

| + | ctinc = -1 #threshold for edge height | ||

| + | peak_can = False #peak candidate flag | ||

| + | first_zero = True #peak candidate zero cross flag | ||

| + | lst_zero = indx_high #bin index of last zero positive zero crossing | ||

| + | peak_int = 0 #integral of peak ie edge height<br> | ||

| + | #the following code find the bin with the sharpest edge based on two criterion. | ||

| + | #the first is that the edge should have a minimum gradient of ctlow | ||

| + | #the second this that the edge height should be at least 1 (arb). Note that the height of the edge is calculated as the height difference between the first point where the edge the bottom of the edge defined (where the gradient is zero, to the top of the edge where the gradient again crosses zero for the third time. | ||

| + | for i,val in reversed(list(enumerate(dfft))[indx_low:indx_high]): | ||

| + | if peak_can == False: | ||

| + | if val > 0: | ||

| + | lst_zero = i | ||

| + | peak_int = 0 | ||

| + | else: | ||

| + | peak_int += val | ||

| + | if val > ctlow: | ||

| + | max_bin = i | ||

| + | elif val < dfft[i-1]: | ||

| + | max_bin = i | ||

| + | peak_can = True | ||

| + | else: | ||

| + | pass | ||

| + | else: | ||

| + | peak_int += val | ||

| + | if first_zero: | ||

| + | if val > 0: | ||

| + | first_zero = False | ||

| + | else: | ||

| + | if val < 0: | ||

| + | if peak_int < ctinc: | ||

| + | break | ||

| + | else: | ||

| + | peak_can = False | ||

| + | first_zero = True | ||

| + | lst_zero = i | ||

| + | peak_int = 0<br> | ||

| + | max_val = dfft[max_bin] #set threshold parameter as the edge bin of interest found above | ||

| + | mean_indx = 0 #variable to store index of velocity <br> | ||

| + | #remove values greater than 0.2 of the peak of the edge, this allows us to isolate the edge | ||

| + | dfft = [(0 if (x > 0.2*max_val) else x) for x in dfft] | ||

| + | def getelt(i): | ||

| + | try: | ||

| + | return dfft[i] | ||

| + | except IndexError: | ||

| + | return 0 | ||

| + | #isolate peak on the right and left sides by setting everything after the first zero to zero | ||

| + | is_peak = True | ||

| + | for i,x in enumerate(dfft): | ||

| + | if i < max_bin: | ||

| + | pass | ||

| + | else: | ||

| + | if (is_peak and dfft[i] < 0): | ||

| + | pass | ||

| + | else: | ||

| + | is_peak = False | ||

| + | dfft[i] = 0 | ||

| + | is_peak = True | ||

| + | for i,x in reversed(list(enumerate(dfft))): | ||

| + | if i > max_bin: | ||

| + | pass | ||

| + | else: | ||

| + | if (is_peak and dfft[i] < 0): | ||

| + | pass | ||

| + | else: | ||

| + | is_peak = False | ||

| + | dfft[i] = 0<br> | ||

| + | #calculate the amplitude as the height difference of the edge | ||

| + | amp = -sum(dfft[indx_low:indx_high]) | ||

| + | #find the center of the edge as an estimate to the velocity | ||

| + | try: | ||

| + | mean_indx = np.average(list(range(indx_low,indx_high)), weights = dfft[indx_low:indx_high]) | ||

| + | except ZeroDivisionError: | ||

| + | mean_indx = 0<br> | ||

| + | #multiply found index by factor to convert to mm/s | ||

| + | mean_indx *= SdPoint.binconv * 0.6#0.6 falling edge mean velocity fudge factor <br> | ||

| + | #return velocity and amplitude | ||

| + | return mean_indx, amp | ||

| + | |||

| + | The flowing is a natural language description/explanation of the algorithm:<br> | ||

| + | |||

| + | The raw data received from the sensor is a time series of samples from the ADC which is connected to the mixer circuit. The FFT of the data is then taken. This FFT is then RMS averaged with 7 others. The algorithm described operates on this RMS averaged FFT. | ||

| + | |||

| + | 1. The FFT is first whitened against the relevant PSD for the sensor by dividing each bin with the corresponding PSD entry.<br> | ||

| + | 2. The log of the whitened FFT is taken.<br> | ||

| + | 3. A convolution is applied to the log of the FFT, this convolution filter applies a Gaussian blue of σ = 2, and a derivative operator. Thus the output is an array corresponding to the smoothed derivative of the data.<br> | ||

| + | 4. A peak detection algorithm is run. To find prominent edges in the FFT. To do this a threshold is set (see above for specifics) and the derivative array is scanned from highest bin to lowest bin until a bin with at least this derivative is found. The array is scanned from highest bin to lowest bin because all the FFT tend to have a very large spike at the low bins which throws off measurements.<br> | ||

| + | 5. Now the 'bump' detection is applied. To do this, starting from the smallest bin above the bin found in 4. which is negative, and descending, the derivative values are summed until the just before the bin where the derivative becomes negative again. This is approximately the next height change over the edge or 'bump', if the net height change is greater than a threshold it is determined that the bin from 4. does indeed correspond to and edge rather than a 'bump' which would return to the same height. If a 'bump' is detected 4. is repeated starting from the bin below the found 'bump'.<br> | ||

| + | 6. Now that a bin in the edge of interest is found it needs to be isolated from the data, to do this any bins after the first zero on the right and left of the edge are set to zero. This creates an array where the only data is the derivatives at the edge of interest.<br> | ||

| + | 7. The amplitude of the point is now calculated as the area under the derivative peak, or the height of the edge.<br> | ||

| + | 8. The velocity is calculated as the weighted mean bin of the derivative peak. This is then multiplied by a conversion factor of get to mm/s, a factor of 0.6 is also included in this which is thought to represent the difference between the mean flow and the fastest moving particles in the flow. | ||

| + | |||

| + | == 23rd November 2020 == | ||

| + | |||

| + | The RMS error can be recomputed using the new algorithm. The results are below, the errors are all less than the previous algorithm. | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! RMS (%) !! Mean error (%) !! N !! u (mm/s) | ||

| + | |- | ||

| + | | 53 || -11 || 26275|| 0 - 250 | ||

| + | |- | ||

| + | | 44 || -22 || 4966 || 250 - 500 | ||

| + | |- | ||

| + | | 26 || 4 || 3059 || 500 - 750 | ||

| + | |- | ||

| + | | 18 || 0 || 1764 || 750 - 1000 | ||

| + | |- | ||

| + | | 42 || -27 || 83 || 1000 - 1250 | ||

| + | |- | ||

| + | | 84 || -82 || 5 || 1250 - 1500 | ||

| + | |- | ||

| + | | 93 || -93 || 10 || 1500 - 1750 | ||

| + | |} | ||

| + | |||

| + | == 5th April 2021 == | ||

| + | |||

| + | An explanation was found for the factor of 0.6 in the velocity algorithm first discussed [[In_Water_Vel_Sensor#Velocity_Algorithm_Description | here]]. This was not in-fact a constant of proportionality between mean flows and fastest moving flows or anything like that but rather just a calibration error. The calibration in the velocity code the 69.7 hertz per bin corresponds to a sample rate of 17.8 kHz. The real sample rate of the sensor was measured to be closer to 11.1 kHz. Taking their ratio we get 0.62, the factor which was multiplied for in the code. | ||

| + | |||

| + | == 16 April 2021 == | ||

| + | |||

| + | Some testing was done to measure the current of the sensor. Sensor ID015 was used. At first the sensors couldn't be communicated with. It was found that the cable was too long for the serial connection so the cable was shortened a bit. The firmware revision used was 0.1.4. | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! Power State !! current (mA) | ||

| + | |- | ||

| + | | Measurement || 27.0 | ||

| + | |- | ||

| + | | Active|| 12.8 | ||

| + | |- | ||

| + | | Sleep|| 0.109 | ||

| + | |} | ||

Latest revision as of 00:08, 22 December 2024

This section documented our journey to develop a low-cost water velocity sensor based on doppler effect!

Check out the full paper!: https://doi.org/10.3390/s22197451

For information on specific velocity sensors see: BoSL Velocity Database

Contents

- 1 20th November 2019

- 2 21th November 2019

- 3 25th November 2019

- 4 26th November 2019

- 5 27th November 2019

- 6 28th November 2019

- 7 29th November 2019

- 8 3rd December 2019

- 9 4th December 2019

- 10 5th December 2019

- 11 9th December 2019

- 12 12th December 2019

- 13 16th December 2019

- 14 19th December 2019

- 15 22nd January 2020

- 16 3rd February 2020

- 17 4th February 2020

- 18 7th February 2020

- 19 10th February 2020

- 20 11th February 2020

- 21 12th February 2020

- 22 13th February 2020

- 23 14th February 2020

- 24 28th February 2020

- 25 6th March 2020

- 26 9th March 2020

- 27 16th March 2020

- 28 24th March 2020

- 29 5th April 2020

- 30 9th April 2020

- 31 11th April 2020

- 32 12th April 2020

- 33 13th April 2020

- 34 14th April 2020

- 35 17th April 2020

- 36 22nd April 2020

- 37 24th April 2020

- 38 27th April 2020

- 39 9th May 2020

- 40 11th May 2020

- 41 12th May 2020

- 42 16th May 2020

- 43 25th May 2020

- 44 26th May 2020

- 45 27th May 2020

- 46 1 June 2020

- 47 2 June 2020

- 48 3 June 2020

- 49 7 June 2020

- 50 26 June 2020

- 51 29 June 2020

- 52 2 July 2020

- 53 3 July 2020

- 54 6 July 2020

- 55 8 July 2020

- 56 12th July 2020

- 57 15th July 2020

- 58 16th July 2020

- 59 17th July 2020

- 60 20th July 2020

- 61 25th July 2020

- 62 27th July 2020

- 63 31st July 2020

- 64 4th August 2020

- 65 6th August 2020

- 66 8th August 2020

- 67 27th August 2020

- 68 8th September 2020

- 69 9th September 2020

- 70 10th September 2020

- 71 11th September 2020

- 72 16th September 2020

- 73 17th September 2020

- 74 4th October 2020

- 75 10th October 2020

- 76 11th October 2020

- 77 18th October 2020

- 78 29th October 2020

- 79 20th November 2020

- 80 23rd November 2020

- 81 5th April 2021

- 82 16 April 2021

20th November 2019

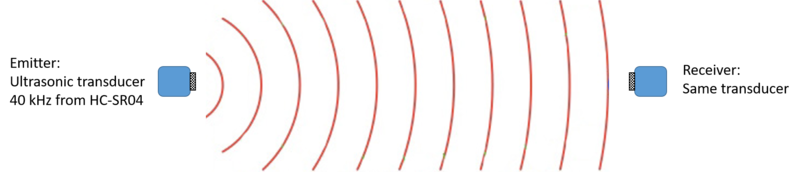

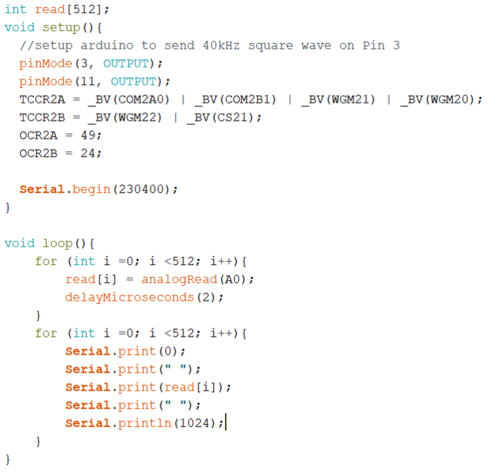

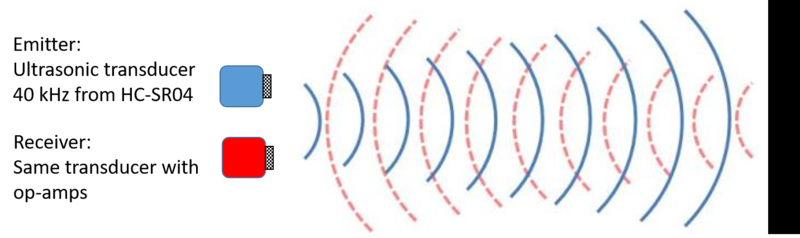

So the first task we are going to try is to use Arduino to generate 40 kHz square wave and emit that signal by using a ultrasonic transducer.

By facing another same transducer to the one emitting the ultrasonic signal, we can successfully detect that signal.

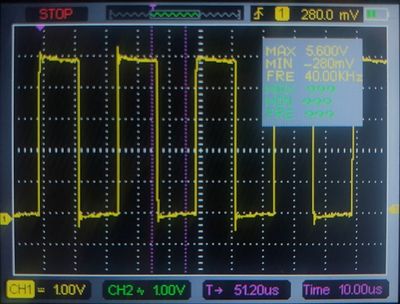

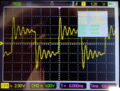

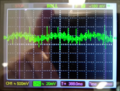

Figures below show the generated square wave from the emitting transducer (measured by an oscilloscope), and the detected wave signal from the receiver transducer (by using AnalogRead).

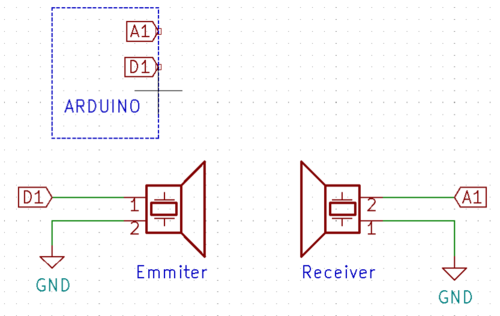

The figure here shows how we wire up the transducers with Arduino to conduct this quick test. The code we used is also attached here to show you how to use Arduino to generate a certain frequency.

21th November 2019

What are we going to try today is to place the two transducers next to each other and facing the same direction.

One emit the signal to a metal wall, and the receiver to detect the signal bounce back.

Multiple op-amps will be used to strength the signal to make it strong enough for Arduino to detect.

25th November 2019

For the arduino to effectively read the low amplitude high frequency signals it is going to need some assistance via external circuitry.

We tested an non-inverting op-amp design based on the LM324. This proved to have challenges reproducing the high frequency signals and after some diagnosis, we determined that the slew rate of the LM324 was too low.

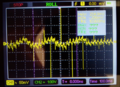

The image above shows the limited slew rate experienced from the LM324N. In this domain the waveform appear as linear as the OpAmp attempts to match the proper signal. It demonstrated a slew rate of about 0.5 V / μS. To overcome this we will need to replace the LM324N with a better OpAmp.

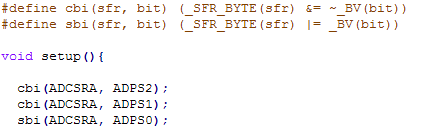

By default the Arduino ADC sample frequency is rather slow at 45 kHz. For our application we will need much faster sampling rates. Fortunately, the clock divider which the ADC runs on (default 32x) is user settable. In testing various values for this, a sample rate of 615 kHz was able to be achieved. <1>

This was accomplished via the following code:

26th November 2019

We tested out some LM883N and NE5532AP OpAmps to see if they performed better than the LM324 (they have a slew rating of ~5 V / μS so they should). Both worked much better than the LM324 being able to reproduce the waveform however, we found that the NE5532AP was better at higher gains.

It was found that the circuit below performed well at amplifying the AC signal of the receiver resonator.

The gain can be adjusted through resistors Ra and Rb via the formula: Gain = 1 + Ra/Rb

Issues were faced where very high noise was present on the output of the op-amp. Some investigation revealed that this was due to the same Arduino driving the 40 kHz squarewave as powering the op-amp. This limited the ability to receive low amplitude signals and made it difficult to detect the reflected ultrasonic waves. A temporary solution to this was to use separate Arduinos for the transmitted and receiver.

A noise profile was obtained by having the ultrasonic receiver covered and placed such that no ultrasonic frequencies would be measured by it. The op-amp output was then measured. Below are the measurements for the two-Arduino setup vs the one-Arduino setup.

The noise is improved in the two-Arduino setup however there is still a significant ammount, it may be necessary to make a PCB with better noise isolation for test which require higher sensitivity.

Arduino Sample Frequency

<1> From doing more test it appears that not all Arduinos are able to sample at the 615 kHz rate, a more reliable max appears to be 215 kHz.

Testing the values of the clock divider registers ADPS2, ADPS1, ADPS0, the following table was made indicating about the various sample frequency on a 16 MHz 5 V ATmega382P (Arduino Uno).

| ADPS2 | ADPS1 | ADPS0 | Sample Frequency (kHz) | Working |

|---|---|---|---|---|

| 0 | 0 | 0 | 325 | No |

| 0 | 0 | 1 | 325 | No |

| 0 | 1 | 0 | 215 | Yes |

| 0 | 1 | 1 | 125 | Yes |

| 1 | 0 | 0 | 66 | Yes |

| 1 | 0 | 1 | 35.6 | Yes |

| 1 | 1 | 0 | 17.6 | Yes |

| 1 | 1 | 1 | 8.9 | Yes |

Arduino Frequency Measurement

To measure frequency an DFT was performed on a 128 size sample at 215 kHz of the amplified ultrasonic receiver signal.The sample frequency was chosen as it was the highest stable, and the sample size as this was the limit of the ATmega382p's memory.

The y-axis height represents strength of that component frequency, and the x-axis the frequency bins, where eight bins corresponds to 1.7 kHz

Concerningly the peak height is at about 90 kHz, and the predominant frequency when measured with an oscilloscope is 40 kHz.

27th November 2019

Some thought was conducted into the feasibility of direct frequency measurement using the ATmega328p and extracting the Doppler shift digitally.

The velocity is given by the equation: v = c/2 (fd/f) cos(θ), where c is the speed of sound, fd is the Doppler shift, f is the emitted frequency, and θ is the angle between the flow and sensor.

Let us assume that the sensor is parallel to the flow (θ = 0). By Nyquist-Shannon sampling theory, to detect a frequency at f we need the ATmega328p to sample at 2f. Applying a DFT to this sample gives a frequency resolution Δf of 2f/N, where N is the number of samples. Therefore, making the substitutions fd = 2f/N, θ = 0, we get: Δv = c/2 (2f/(f*N)) = c/N

For water (c = 1500 m/s) and a velocity resolution of Δv = 0.1 m/s this implies that 15 000 samples would need to be taken. This would require an amount of memory well beyond the 2 kB of the Arduino (which can realistically only store 128 samples).

This implies that direct measurement of the Doppler shift is not feasible and that some signal pre-processing is necessary. The idea is to extract the Doppler shift so that we can have a easier time sampling the lower frequency Doppler shift signal.

There are two approaches which we are going to trial, amplitude demodulation, and a heterodyne converter.

Amplitude Demodulation

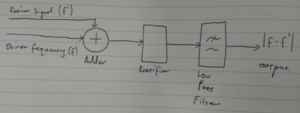

The premise of the AM demodulator is that the sum of the two signals produces a beating frequency (f' - f) which is conveniently also the Doppler shift fd. The rectifier eliminates the negative peaks of the resultant sum, and the low pass filter blocks the high frequency carrier wave of the signal, leaving only the low frequency Doppler shift.

The draw back of this method is that the signal is very weak, and it is difficult to scale to higher frequencies.

A pathfinder version of this circuit was constructed as indicated in the diagram. The inputs were provided by two Arduino Unos with one generating a 40 kHz 5Vpp Square wave, and the other a 43.4 kHz square wave. The output as measured by an oscilloscope was good, displaying an about 3.4 kHz wave which was the difference in the two frequencies. The output was however, a bit noisy, and low in amplitude (~500 mV). Building this on a proper PCB should help eliminate some of the noise and allow the output to be amplified.

The 43.3 kHz Arduino was then disconnected from the circuit and the ultrasonic transducers were wired into the circuit, (with some appropriate changes to the resistor values). The transducers were then placed so that they were facing each other and then the receiver was moved back and forward at a steady rate. The output of the demodulator was able to detect the Doppler shift and thus this motion, however much noise was present and the signal was weak.

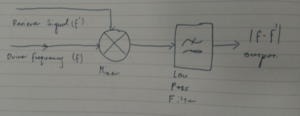

Heterodyne Pre-Processing

The Heterodyne is more standard for high frequency Doppler shift applications, the mixer multiplies the two signals. For two sine waves with frequencies fa and fb, their product will be the sum of cosines with frequencies |fa-fb| and |fa + fb|. For fa = f', and fb = f, the lower frequency signal is the Doppler frequency, which can then be isolated from the higher frequency using a low pass filter. This method provides the advantage of it being proven to work at a wide range of frequencies, in excess of 500 MHz.

28th November 2019

Following on from yesterday, I tested to see if the Arduino could analyse the output of the AM demodulator circuit. The output of the circuit was connected analog pin A1, and the below code was run.

The code, generates a 40 kHz 5 Vpp square wave on pin 3, then samples at 100 Hz on pin A1 for 128 samples. This data is then passed on the arduinoFFT library when does a DFT on the data to convert it into the frequency domain. The frequency domain data is then plotted to serial.

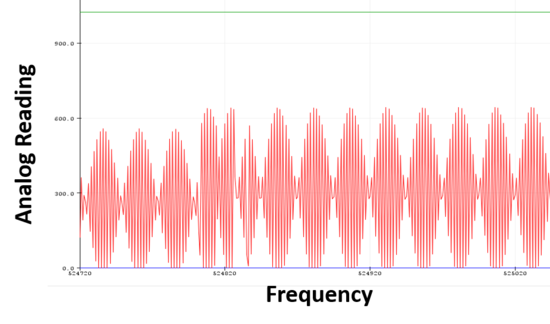

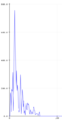

Running this code while moving the ultrasonic sensor at about 4 cm/s. The FFT in the gallery was the output.

The peak is seen at about bin 10. The bin frequency is given by fb = fs/N, where fs is the sampling rate (100 Hz in this case) and N the number of samples (128). This gives a bin frequency in our case of 0.78 Hz. As we are interested in bin 10, our Doppler frequency is 7.8 Hz.

Using the formula: v = c/2 (fd/f) => v = 340/2 (7.8/40 000) => v = 3.3 cm/s

Which is within our margin of error for the velocity, and indicates that the principle behind the sensor is as observed.

AM Demodulator PCB

PCB drawn up to take the AM demodulator off the breadboard and hopefully reduce some noise. Off to the Voltera!

Note: C1 was changed to from 1 μF to 100 nF as it had better performance.

The circuit works well, much the much better noise floor creates greatly improves the signal to noise ratio. The signal is still a bit weak however some more amplification may help this out. An oscilloscope is able to detect the Doppler shift when the transducers are facing each other and one is moved from about 1 meters distance, and from about half a meter when the signal is bounced off a wall. It is hoped that optimization of the values of the components can improve on this.

Additionally, it still needs to be tested if the Arduino can detect the signal from this.

When the traducers are facing each other, the Arduino is able to read the voltage and perform the analysis on it. Below is an FFT plot from the Arduino in this arrangement.

Wrote some code to use the frequency data to determine the speed. Initial tests indicate its working well, although a proper trial with calibrated speed references will be necessary to be sure if its working properly.

29th November 2019

Some tuning was done to the AM demodulator circuit to improve performance. One issue found when probing with the oscilloscope is that the output of the opamp was being clipped as the amplification was too large, and so the resistor R6 was changed to 5 kΩ to prevent this.

3rd December 2019

Some testing was done into if it would be possible for an Arduino to produce a 1 MHz frequency, which will be needed if we want to switch to a 1 MHz transducer. It was able to generate the waveform, however, significant ringing did occur on the rising and falling edge. This may be able to be alleviated with a capacitor if it becomes an issue.

Heterodyne Circuit

In order to switch to using higher frequencies the heterodyne circuit topology is going to be needed. A circuit based on the SA612AD is going to be build according to this schematic.

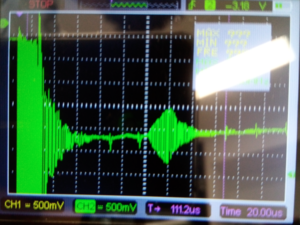

Building this circuit, it seems to perform effectively, and with a output signal much cleaner and stronger than the AM demodulator. The waveform in the gallery was taken with the two 40 KHz ultrasonic sensors pointing towards a wall about 30-50 cm away. The amplitude of the signal being about 80 mV should be able to be detected by the Arduino, however if not the output signal is SNR is low enough that amplification could be done. Furthermore, it seems as though the low pass filter has a much easier time of isolating the low frequency component of interest when compared to the AM modulator, another benefit of this design.

For two 40 KHz ultrasonic sensors facing each other at about a half a meters distance, the Arduino was used to record the output of the Heterodyne Circuit. The FFT of the signal is shown below. It is seen that the signal produces a much more distinct peak at the Doppler frequency, which will help the extraction of the velocity from this output.

In investigating the SA612AD, the two RF inputs IN_A and IN_B can be used to form a ballanced line. Connecting either side of the Ultrasonic transducer to a these pins through a 100 nF series capacitor, reduces the noise which is introduced into the amplifier, and so improves the sensitivity of the circuit.

1.7 MHz Tranducers

Having success in measuring the Doppler shift at the lower frequencies, it is time to test out the higher frequency ultrasonic transducers.

The specific piezoelectric disk which we going to be testing is: https://au.mouser.com/ProductDetail/PUI-Audio/UB161M7?qs=pFWzdYhrkoc8QGl1JZ231g%3D%3D

It has a rated resonant frequency of 1.7 MHz, however the Arduino is only able to produce frequencies an integer division of its clock frequency (16 MHz). It was found that out of the frequencies which the Arduino could generate (16 MHz / 9 = 1.78 MHz) produced the largest resonance in the ultrasonic transducers.

These disk do not come with any wires soldered to them and so this needed to be done manually. Something which was quite difficult as the solder contacts ideally should be quite small.

In modifying the above Heterodyne circuit for use with the 1.7 MHz tranducers, I found that the grounding on the breadboard is not good enough for a low noise output. I might have to make a PCB for it, or add better grounding.

The noise was not able to be solved easily, and so a PCB is going to be made.

4th December 2019

Little success was had with the PCB, the higher frequencies of the 1.7 MHz tranducers results in many more complications in the circuit design. Additionally, with the multiple problems present it is difficult to isolate and diagnose how each part of the circuit affects the overall performance.

In testing the circuit works well at 40 KHz, better heterodyne circuit built on the breadboard. As the IC is rated for operations up to hundreds of MHz, this narrows down the source of the issue to be either, the ultrasonic tranducers, the signal integrity, or the values of some of the components being unsuitable for MHz work.

Transducer Resonant Frequency

I measured the resonant frequency of the two 1.7 MHz traducers using the oscilloscope. The values were quite a bit off from 1.7 MHz with one being 1.64 MHz and the other 1.63 MHz. It is likely that this shift is because of the wires which needed to be soldered on to the traducers. This shift could also be one of the reasons that the circuit is working.

In re-reading the datasheet and conducting some testing on the tranducers, they are a type of transducer known as a bender. This type is more suited towards high voltage application 10s of Volts, and is not suited to detecting small pressures as are those found in ultrasonic air waves. These tranducers do not have the characteristics necessary for our application, and so hopefully the ones in the post are better.

1 MHz Transducer

I had a bit of a test with the 1 MHz ultrasonic tranducer: https://www.digikey.com/product-detail/en/unictron-technologies-corporation/H2KLPY11000600/2047-H2KLPY11000600-ND/9921487, to see if it was able to detect a reflected signal.

The setup was to send 20 1 MHz pulses to the transducer and then use an oscilloscope to monitor if any reflected signal was present.

In air this was not able to be done. Varying the distance didn't seem to help either no reflected signal ever being detected in the osciloscope.

In water however, the results were quite successful. The waveform attached is of the transducer facing down into a cylinder of water about 15 cm high, the surface of the transducer was touching the water. As can be seen the reflected waveform produces a distinct peak, some time after the driving pulse is stopped.

The reason that the trial in water worked, whereas the one in air didn't is probably to do with impedance matching. That is at higher frequencies, much less of the vibrational energy gets transferred from the tranducer to the low density and slow speed of sound air than compared to the more dense and higher speed of sound water. This is something which we will need to pay close attention to as we wish to maximize the amount of energy that gets transferred into the medium, so we can have an easier time detecting the reflections.

5th December 2019

We found some new 1 MHz ultrasonic transducers, and they seems to be more suited towards transducer application: (https://www.steminc.com/PZT/en/piezo-ceramic-disc-10x2mm-r-215-khz-wire-leads-smd10t2r111wl).

I tested the resonant frequency and found it to be the quoted 1 MHz.

Good news! The transducers are transduceing, that is to say, using the oscilloscope you can detect the oscillation of the driven transducer with the receiver transducer. It is important to note here that these tests were done in water as in air the coupling is too weak.

The tranducers also seem to have a resonant frequency at just undre 250 kHz, about 243 kHz. This one actually seems to be stronger, with more signal being transduced at this frequency.

The reflected pulse off the bottom of a cylinder of water was not able to be measured by this transducer, as with the previous 1 MHz transducer.

In doing some preliminary testing, it is looking like all of the MHz tests are going to need to be conducted in water. Additionally, it appears as though the container shape matter as the ultrasonic waves tend to reflect off the walls and create resonances in the cylinder, this interferes with the signal.

With some adjustment to the capacitor C? from 68 pF to 170 pF, I was able to get a signal out of the Heterodyne circuit when both of the transducers were facing each other. The signal was weak and still had a significant 250 kHz component, but it was able to be measured with an oscilloscope.

9th December 2019

Some new ultrasonic transducers arrived. They are already enclosed and wired up so they look more promising than the other ones.

I used the function gen and oscilloscope to get a precise reading on the resonant frequency in air and it is about 1.018 MHz. This value was obtained by finding the local minimum in amplitude across the traducer, with a series 330 Ω resistor, when sweeping through the frequencies using a function gen.

In water the resonant frequency was 0.999 MHz, which is within the measurement error for the manufacturers quoted 1 MHz

I conducted another test in which I applied a 1 MHz frequency to one transducer in water and measured the voltage across another transducer with an oscilloscope. A few good things to note from this was that more voltage across the input transducer produces a stronger signal on the output transducer. The relationship is not exactly linear but it is fairly proportional, with diminishing returns occurring at larger voltages. Also, the arrangement of the transducers is very important, they need to be facing each other or have a good path through a reflection off a wall. Otherwise the signal is almost undetectable.

I hooked up the transducers to the Heterodyne circuit with the Signal Gen providing the 1 MHz input wave. Using an oscilloscope I am able to detect the motion of the transducers. The signal is very weak and still superimposed with the 1 MHz input wave so I am unable to upload a meaningful image of it yet.

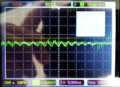

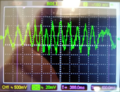

Passing the signal through a low pass filter (f = 4.5 kHz), the doppler shift becomes much more visible on the oscilloscope. In this setup the transducers were placed such that the wave reflected off the bottom of a cylinder of water. The input wave did have to be increase to 9 Vpp, however this can be reduced later once the circuit is tuned correctly. Attached are two images one of the output when the receiver is still and one when it is being moved very slowly, (> 1 cm/s). The Doppler frequency is clearly visible when comparing these two, I suspect that the low frequency wave in the no motion waveform is an artifact of the oscilloscope.

At this point, the circuit-transducer combo is quite well tested, and it is time to look at getting a proper PCB manufactured and encasing the transducers.

12th December 2019

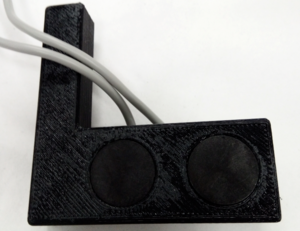

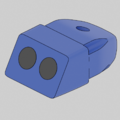

A housing was printed for the ultrasonic sensors to keep them well aligned and as a prototype for the final packaging of the sensor.

16th December 2019

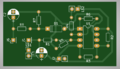

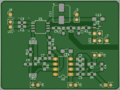

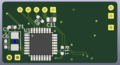

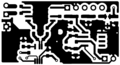

A schematic for the PCB was drawn up. It features an onboard 1 MHz clock generator to provide the stable 1 MHz signal needed for the Tranducers, and it outputs the low frequency Doppler shift.

A rendering of the PCB is also shown in the gallery.

19th December 2019

The heterodyne circuit and the 1 MHz tranducers were tested in the 3D printed casing in a water sink. The output was very good for movement of the sensor, (photo in gallery), with the signal being many times the noise level. Granted, this was with a input voltage of 9 V, but this would be able to be reduced in the future.

Motion of the water, however, proved to be more difficult, it was generally undetectable, expect for very fast velocities. The signal to noise amplitude ratio never exceeded one. This domain is the one we are interested in to measure the fluid velocity, so much more optimisation of the design will be needed if the signal is to become Arduino readable. It is noted that tap water was used to fill the sink, which lacks the particles necessary to get a good reflected ultrasonic signal. It is presumed that in storm-water their will be more particles present so this will help in making the signal stronger.

The water velocity signal was too weak to get a useful screen grab from the oscilloscope.

22nd January 2020

The new PCB designed to reduce noise and enable a higher sensitivity reading was soldered and tested today. The noise floor for a 5 V 1 MHz Arduino generated square wave was about 20 mV. When tested in water the Doppler shift off a hard surface such as the sink wall was able to be clearly detected, however no signal was had with just the flowing water. The J4 output was much worse performing than the JP1 voltage point. This is likely due to the ground noise making the low pass filter (C8, R11) ineffective. The balanced line amplifier has not been tested yet so it is still to be seen if this method produces a cleaner output. Grounding the EMF shield of the Doppler transceivers had little effect on the noise performance of the device.

Switching from a driving signal generated from the Arduino to one generated from the integrated oscillator, the noise floor dropped to below 5 mV, a substantial improvement. However after the traducer was plugged in the noise increased substantially. Reflections were still able to be detected off hard surfaces. Tests as to whether it could detect flowing water were inconclusive. This time the (C8, R11) low pass filter did help improve the signal quality. At this point I am thinking that the much increased noise level has to do with the much lower impedance of the transducer when compared to the open circuit, thus requiring larger current draws from the oscillator and creating more interference. One possible method of trying to overcome this is to not use the direct signal from the 1 MHz square wave oscillator to drive the transducer but instead to take the first pass it through the low pass filter system which produces a sine wave for pin 3 of the mixer and then amplify that using the unused channel of the op amp. This should work better as the sine wave does not have any higher than 1 MHz harmonics like the square wave does and so the amplification of this signal should produce less interference.

After testing amplifying the sine wave works to reduce the interference of once the transducer is plugged in. However the problem is now that the op-amp selected does not have a high enough gain at the 1 MHz signal. A gain of around 25 would be desired. The NE5532 used can only achieve a gain of 4 or 5 at this frequency. The two best options to overcome this would be to look for an op-amp which has better characteristics at this frequency or to implement a two stage amplifier in which the output of one op amp is fed into the next.

Testing this setup in water it seems that the 1 V signal from the single NE5532 is still strong enough for the returned signal to be measurable. Due to the low noise the signal is now very clean and easily readable, so it is worth considering whether the driving voltage for the transducer needs to be amplified more or whether it is good as is. Water velocity flow is still unable to be detected. The signal off the reflection from water is at least several times weaker than hard surfaces, and it is hard to get a consistent flow of water in the sink I was using so it was difficult to see whether the signal was due to the flow of water or just random noise in the circuit. Having a large steady flow of water in some test apparatus would help with this, as would using the balanced line amplifier on the circuit to get a better resolve the small signals.

3rd February 2020

Analog characterisation of the heterodyne circuit

The heterodyne circuit was tested for its analog performance using the following circuit

The circuit was powered on and then the function generator was used to imitate the return signal from the receiving ultrasonic traducer. First the frequency of the function generator outputting a 100 mVpp sine wave was tuned such that the frequency matched that of the in-circuit oscillator. This frequency was found to be about 1.000 32 MHz +- 1.000 01 MHz. From here frequency was shifted up to 1.000 350 00 MHz to produce a signal on the output of the circuit, a frequency which roughly corresponds to a flow velocity of about 2 cm/s. The amplitude of this signal was measured with the oscilloscope. This method produced the graphed relation between input signal amplitude and output signal amplitude.

From the graph it is seen that the noise floor is about 20 mV however voltages as small as 5 mV are still able to produce a distinguishable signal. The device has good sensitivity to small input signals and amplifies the input with a gain of about 3. The voltage produced by a ultrasonic receiver in water has not yet been tested, however it is likely to be quite small, so any performance improvements achievable here would be welcome. To feasibly measure the signal with the Arduino the voltage amplitude needs to be on the order of 10s of millivolts ideally greater than 50. To accomplish this the on-board amplifier will now be activated and the device will be retested.

The in-circuit amplifier turn out to be difficult to get working. Issues with the design of the amplifier lead to it being very unstable with positive feedback loops oscillating the signal between both supply rails. An amplifier more suited towards amplifying the balanced line output of the SA612AD and should be implemented on the next revision of the PCB. The new amplifier only has 20 dB/decade roll-off however this should be sufficient to filter out the 1 MHz carrier from the 100s Hz signal.

Other design ideas which could be implemented to help out with the signal acquisition could be to use the Aref pin of the Arduino to feed in a 100 mV signal, thus making the range of the ADC smaller and the measurements more precise. Another idea is to add an independent I2C ADC onto the velocity circuit board. This has the advantage of using fewer wires in the cable and also dose not need to analog signal to travel the long distance up the cable where the signal quality would be degraded due to interference.

The signal was connected to an Arduino and an FFT was taken on the data (N = 128, fs = 1000 Hz). The arduino was easily able to detect the frequency shift of a 1 mV signal input into the receiver ultrasonic transducer. The memory limitations of the Arduino create range restrictions on the data. At a range which would include the flow velocity of 2 m/s the resolution is 0.03 m/s. To overcome this traditionally would require more samples to run the FFT on however as mentioned the Arduino does not have the memory for this. Another more resource efficient solution is to take two reading, one at a higher sample frequency and one at a lower sample frequency. This way the lower sample frequency will have the resolution to distinguish slow flow velocities, and the high sample rate fast velocities.

4th February 2020

The velocity sensor was tested in the flume to check to see if it is able to receive a signal in the water to any extent. The velocity sensor was attached to the flume as shown in the photograph below.

The sensor was originally attached through a 2 m Cat-5e Ethernet cable however this was found to diminish already small signal too much, so the Arduino was connected directly to the Heterodyne circuit. Once integrated and installed in-situ this would be unfeasible and so it is going to be necessary to include a ADC converter on the circuit.

In this arrangement the FFT was able to distinguish a peak at the Doppler frequency of the flow. The peak was very weak and not apparent on all sample readings, however it was present and observed to shift left and right with the changing speed of the water in the flume. When the maximum frequency (converted to water velocity) was printed to serial and compared to a proper water probe the reads showed some correlation with the BoSL sensor being within 50% of the proper probe. The current signal analysis is not good for velocities above 330 mm/s or below 50 mm/s so dynamic sample rate adjustment will need to be implemented to solve this

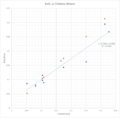

The data was taken with the BoSL probe and a FloMate probe in the flume at a range of water velocities, the graphed data is below, the series of orange points is the 1:1 curve.

The graph shows reasonable correlation between the FloMate probe and the BoSL probe, with it measuring consistently less at higher velocities, however being better in the region below 0.1m/s flows.

7th February 2020

Sample Intervals

The Arduino FFT code was tested to see how reliably it measures frequency. The function generator was used to generate a 100 mVpp sine was inputted directly into analog pin A1 on the Arduino. The Arduino sampled this wave at 2000 μs, 1000 μs, 500 μs and 250 μs intervals for 128 points and then an FFT was performed on the data. The maximum frequency of this FFT was then recorded as the measured frequency. A plot of a range of frequencies is shown below.

The linearity of the frequency measurements is good with all sample intervals being roughly concordant with each other and the input frequency up until their max frequency threshold. At this point, the measured frequency decreases linearly with increases in the input frequency until the measured frequency is zero again, it then goes back to increasing linearly until max frequency threshold, with this cycle repeating with some drifting occurring in later after several 'reflections'. This phenomena provides an interesting way to extract more resolution out of high frequency at a lower memory cost than increasing the number of sample points. The small sample interval FFT could be used to get a rough idea of the frequency and then this could be refined by checking where the large sample interval is between its minimum and maximum sample frequency.

Circuit Supply Capacitor

The heterodyne circuit currently uses a 330 μF capacitor on the power input between +5V and GND. This is unideal as everytime the device is to be switched on this capacitor needs to charge up, requiring a large amount of current, and so using up the battery quicker. The capacitor is necessary to smooth instantaneous surges in current draw from the circuit, reducing the noise, however the capacitance of the capacitor is likely able to be reduced without significantly affecting performance. To test this the FFT plot produced by the Arudino with no input signal on the heterodyne circuit (but the ultrasonic tranducer still plugged in) was recorded for input capacitance of 0 μF, 3.3 μF and 330 μF with plots included below.

The four regions of signal are the four FFT at sample intervals: 2000 μs, 1000 μs, 500 μS, and 250 μs. From these plots it is seen that having no capacitance increase the noise by about 30% - 50%, however having a 330 μF capacitor does not significantly decrease the noise over a 3.3 μF capacitor, and a 3.3 μF capacitor will be used going forward.

Downstream Flow Testing

The velocity sensor was positioned to face downstream in the flume, and the reading was compared to the FloMate to produce the following graph.

The data is very non-linear demonstrating that the BoSL velocity sensor does not work when facing downstream. One possible explanation to be investigated is that the probe has a flat rectangular shape and so the flow behind the probe is severely disrupted, having a more turbulent flow. Making the upstream facing profile of the sensor better maintain flow could be helpful in mitigating this.

Upstream Flow Testing

The velocity sensor was then turned around to face downstream and the performance of the multiple sampling intervals was tested. For each flow velocity the average reading over one minute is plotted.

The error bars represent the quantisation range of the FFT, thus giving some reading of the error in the value. The dashed line shows the linear correlation of an ideal sensor. The sensor shows good agreement with the FloMate for at least one of the sample intervals per point. The slower sample intervals perform better for the slower velocities and the faster, the higher the 250 μs sampling interval has the unideal behavior of measuring far off form the actual value when the flow velocities drop below about 80 mm/s, this should be carefully considered when converting between the four given velocities and a final velocity figure, as it could be mistaken for a faster flow.

10th February 2020

An ADC is to be implemented on the heterodyne circuit board to reduce signal quality losses in the analog transmission of the signal along a wire. A MAX11609 was first tested to see how it performed at sampling quickly. The ADC is an I2C device and so a small code loop was written to test the sample frequency. A frequency gen was connected to the ADC and the amount of sine waves which could be sampled in a given number of samples was counted to find the sampling frequency.

The sample rate was found to be about 2.7 ksps

Enabling External Clock Mode the sample rate was able to be boosted to about 4.9 ksps

The MAX11645EUA+T ADC's arrived, featuring an extra 2 bits of resolution. In external clock mode these ADC's can reach sampling rates of 5.29 ksps. Differential probing was also able to be used meaning it is ready for integration onto the heterodyne PCB.

The heterodyne PCB was modified to use the MAX1645EUA+T ADC instead of the analog output. In order to accomplish this the unbalanced low-pass filter was disconnected and two 330 Ω resistors and a 33 nF capacitor were used to make a balanced low pass filter between the two outputs of the mixer. The outputs of this filter were then directly connected to the inputs of the ADC. The ADC was secured to the circuit using a breadboard with also served to connect the digital I2C bus to the Arduino. In the current configuration the ADC is running of a 3.3 V supply whereas the rest of the circuit is running of a 5 V supply. The main concern with switching the whole board over to 3.3 V is that it is uncertain how the reduced output of the ultrasonic transmitter, due to its lower driving voltage, will affect the strength of the signal returning in the ultrasonic receiver.

11th February 2020

The new ADC displays much improved FFT amplitude resolution and is able to distinguish a small frequency peak much better than the Arduino as able to. The FFT below is of a 1 mV signal, it can be seen that the SNR is now well above one hopefully implying that the Doppler peak in the water is much easier to resolve.

With the new ADC the sample rates change due to having a different code sequence, and a new calibration of the FFT need to be conducted. To do this, a frequency gen was connected to the input of the ADC and a 60 mV sine wave was applied at various frequencies. The FFT bin over 4 averages which this fell into was then recorded the results were graphed.

The graphed region for each sample interval is when they are below their threshold frequency. As seen the output for all of the sample intervals is quite linear and the gradients can be used to convert from the FFT bin into an actual frequency measurement for the Doppler velocity calculations. The sample intervals could be changed to get a better spread over the input space if required.

The sensor was then tested in the flume again however the water velocity was not able to be measured this time as there were prominent spikes in the FFT not related to the water signal. The

These spikes were able to be reproduced by running the cables for the ultrasonic receiver and emitter next to each other, and so it is likely that this is the source of the interference. Connecting the shielding of the transducers to ground eliminated this issue in the out-of-flume testing.

12th February 2020

The circuit was switched over to 3.3 V and on first inspection it seems to be working well. The input into OSC_B on the mixer was found to drop to just about 200 mV when the oscillator was powered using 3.3 V, above the minimum threshold.

A re-calibration of the FFT frequency bins will need to be completed to get a better spread over the potential range of velocities.

The length of the cable was tested and it was found that the sampling speed changed slightly with a longer cable, this is problematic and it is likely that code changes will need to be made to make the timing more resilient. The cable length of 2 meters was able to be used on the 100 kHz speed but smaller pull up resistors (1 kΩ) were needed to be able to communicate with this sensor in fast mode (400 kHz). The downside of this is that it will draw more power and so might need some circuitry to disconnect these pull-up resistors when not in use.

This value of pull-up resistor did not work for a cable of 10 m length.

Peak Finding Algorithm

The previous algorithm used to determine the maximum frequency was to find the FFT bin with the highest amplitude. This worked alright however it suffered from the limitations of not accounting for the width of the peak and being rather jittery. The need to account for the width of the peak is important as for variable flows the Doppler frequency changes slightly and so the peak is spread over multiple bins, reducing the maximum amplitude. The area of the peak, however is more consistent in this case less susceptible to noise.

The peak finding algorithm implemented now works by first isolating the predominant peak and then finding the weighted average of this peak. Specifically, it first makes the mean of the FFT data set zero, following this it subtracts 3 and makes all negative values equal to zero. This works well to get rid of most of the baseline noise and leave only peaks. Following this the highest point is found and then the all values which are not after the first zero bin on each side of this peak are set to zero. This ensure that only one peak is in the data set if there happened to be another due to interference or excessive noise. The weighted average center of this peak is then found and this value is used as the FFT bin for the Doppler shift. The sum of all the bins in the peak is also taken and if this value is less than 10 a flag is raised indicating that the peak was small and might be due to noise rather than actual signal.

13th February 2020

Due to the wire length limitations found yesterday it is being investigated whether having a micro-controller on the velocity sensor itself is a viable option. One though with this is to use the 1 MHz oscillator already on the board as the clock for the micro controller. It is uncertain however if the I2C interface will be able to run on a micro-controller with such a low clock so this is going to be tested.

In testing on an Arduino Uno and changing the clock frequency with the avr/power.h function clock_prescale_set() the clock was able to be reduced to 4 MHz at the I2C bus speed of 200 kHz before it was no longer able to communicate. This means that an external oscillator will be required for the Arduino.

3.3V Calibration Probe Calibration

The sensor was again tested in the Flume against the FloMate with the measurements plotted below.