Difference between revisions of "Radar Velocity"

| (32 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

<b>SUMMARY</b><br> | <b>SUMMARY</b><br> | ||

| + | Check out the full paper: [https://doi.org/10.3390/s23146314 https://doi.org/10.3390/s23146314] <br><br> | ||

Extended abstract submitted to SPN2022: [[File:BoSL Radar sensor extended abstract.pdf]] <br><br> | Extended abstract submitted to SPN2022: [[File:BoSL Radar sensor extended abstract.pdf]] <br><br> | ||

For instructions on how to assemble the sensor please see the wiki page [[Assembling the Radar Sensor]] <br><br> | For instructions on how to assemble the sensor please see the wiki page [[Assembling the Radar Sensor]] <br><br> | ||

| Line 1,250: | Line 1,251: | ||

{| class="wikitable" | {| class="wikitable" | ||

|- | |- | ||

| − | ! Mode !! Peak Current (mA) !! Time (ms) !! Charge (mA.s) | + | ! Mode !! Peak Current (mA) !! Time (ms) !! Charge (mA.s) !! Average Current (mA) |

|- | |- | ||

| − | | sleep|| 100 (nA) || -- || -- | + | | sleep|| 100 (nA) || -- || -- || -- |

|- | |- | ||

| − | | idle || 4.68 || -- || -- | + | | idle || 4.68 || -- || -- || -- |

|- | |- | ||

| − | | measure || 64 || 7020|| 267.2 | + | | measure || 64 || 7020|| 267.2 || 38.1 |

|} | |} | ||

| Line 1,262: | Line 1,263: | ||

idle: current with mcu on but accelerometer and radar off </br> | idle: current with mcu on but accelerometer and radar off </br> | ||

measure: the sparse and fine measurement + dsp for both </br> | measure: the sparse and fine measurement + dsp for both </br> | ||

| + | |||

| + | These tests also demonstrate the benefit of moving the processing onto the STM32 chip. Charge needed for a single measurement is approximately half of what it used to be and the measurement time is reduced by 1.5 seconds. | ||

| + | |||

| + | == 3rd February 2022 == | ||

| + | |||

| + | Some sensors in the field have developed an issue by where the fine depth measurement has avoided values which are a multiple of 60 mm. To determine the cause of this it is first necessary to try and replicate this effect in the lab. To do this a velocity sensor will be set to perform fine measurements and the sensor will be gradually lifted from the ground. The distance from the ground and the measured distance will be recorded. Using this method the issue can be reproduced. At certain distance above the ground the distance measurement will not be constant by it will oscillate between two measurements about 30 mm apart. The physical distance from the sensor at which this issue occurs does not seem to be affected by the sweep start parameter. | ||

| + | |||

| + | == 6th February 2022 == | ||

| + | |||

| + | A potential solution was found by changing some of the envelope sweep settings for the XM132. Specifically we change the profile from profile 1 to profile 2, and the number of measurements from 6 to 12. The profile 1 profile 2 distinction changes the radar pulse length. This reduces the resolving power of the sweep, however given that the water surface will often be the dominant reflection, this shouldn't matter too much. | ||

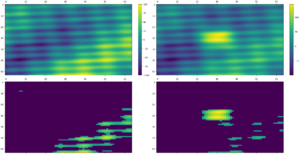

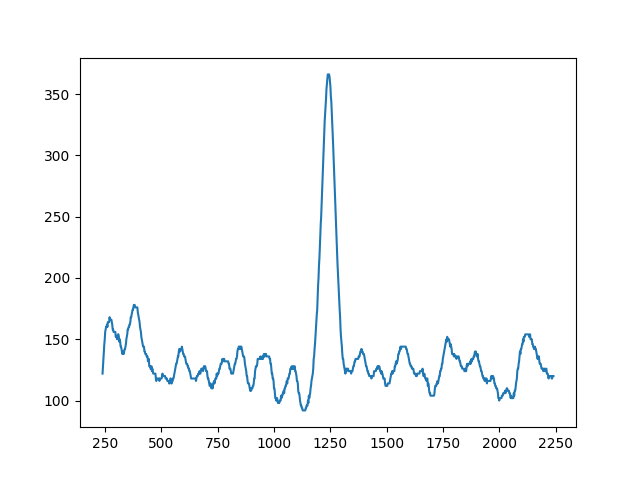

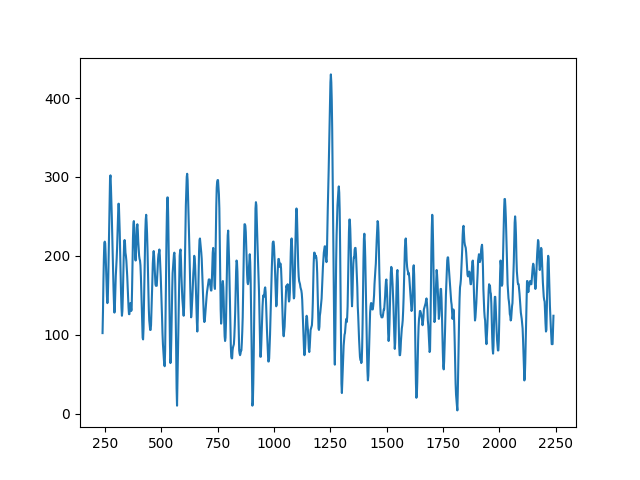

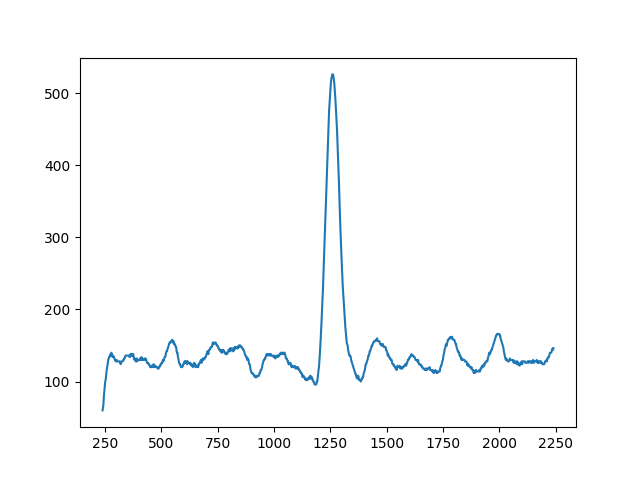

| + | As an example of the issues had with the previous settings, and the discontinuities in distances reported, 4 of the returned envelope measurements are reported. The y axis is signal strength and the x axis is the radar distance (mm). | ||

| + | Two important features can be distinguished here. The first being that peak has much higher visibility on profile 2, and the second being that at some distances from the sensor the peak signal becomes weaker at certain distances from the sensor. On the new settings however the peaks to not diminish below the noise level and so still remain resolvable. | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! !! profile 1, 6 ave !! profile 2, 12 ave | ||

| + | |- | ||

| + | | 22 mm|| [[File:1 6 22.png]] || [[File:2 12 22.png]] | ||

| + | |- | ||

| + | | 40 mm || [[File:1 6 40.png]]|| [[File:2 12 40.png]] | ||

| + | |} | ||

| + | |||

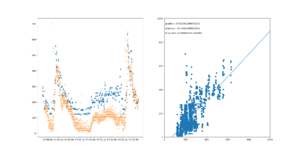

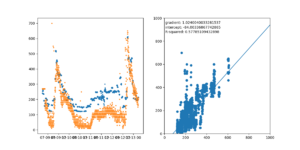

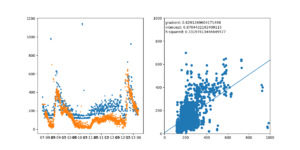

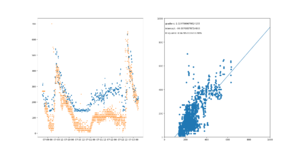

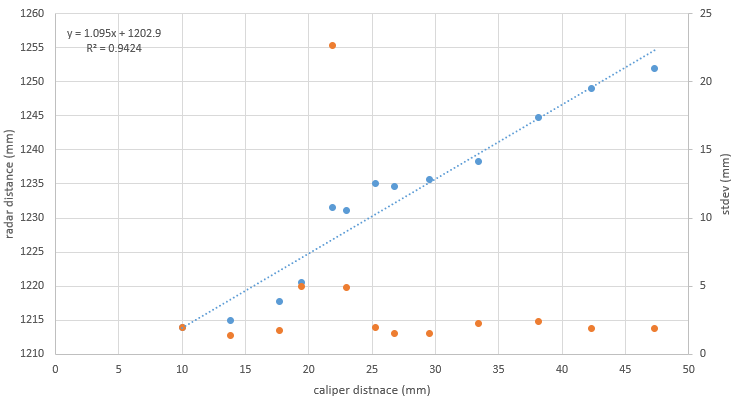

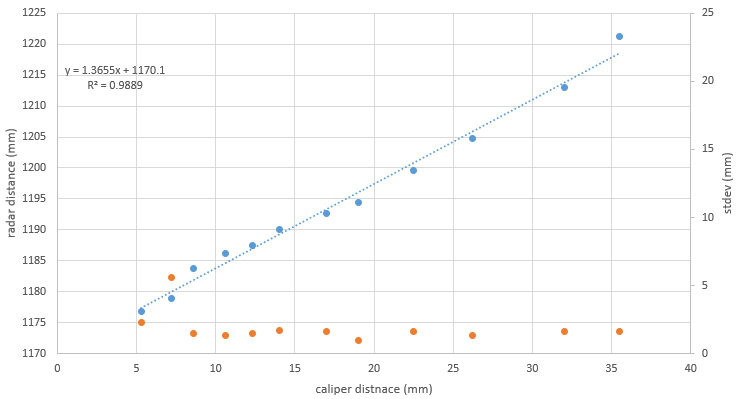

| + | A graph of the reported distance from the radar sensor versus a relative distance measured by a calliper can be measured for both profile settings. In these graphs the discontinuities of the depth sensing are visible on the profile 1 settings, however the graph becomes much more linear on profile 1. The gradient of the line should not be 1 in these graphs as this has not been corrected for the sensor velocity. | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! profile 1, 6 ave !! profile 2, 12 ave | ||

| + | |- | ||

| + | | [[File:P1 corr.png]] || [[File:P2 corr.png]] | ||

| + | |} | ||

| + | |||

| + | == 9th May 2024 == | ||

| + | |||

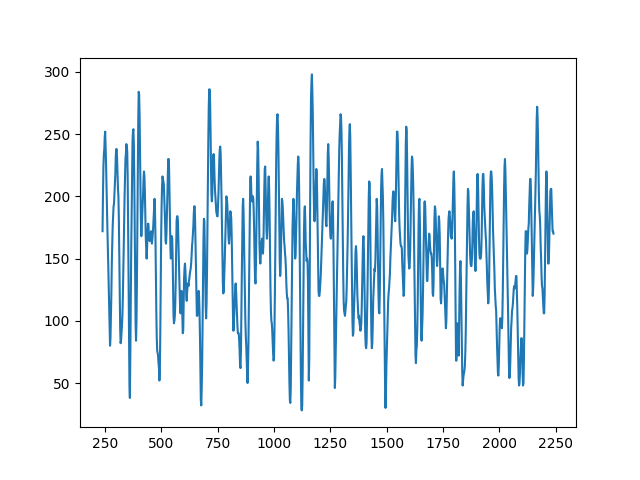

| + | The challenge of detecting when a velocity reading is due to low or no signal (the "300mm/s line") is something I have returned to investigating. | ||

| + | Originally I had hoped to use the data gathered in the FTP trials at old joes creek in 2021-2022 however, after an initial inspection, I noticed that this dataset does not have a large amount of the nosignal data. The data that is present is quite noisy, so much so that it is difficult to determine the true velocity from it (the hach velocity data is also patchy). | ||

| + | One quick change that can be made immediately is to turn on the calculation of spread with a threshold of 0.6. This will calulate the weighted mean square distance of all points above 0.6 of the peak value. | ||

| + | The idea here is the spectral power should be distributed in frequency and distance when the signal strength is low (hence high mean square distance), and concentrated in a central peak when the signal strength is high (hence a low mean square distance). | ||

| + | |||

| + | == 20th May 2024 == | ||

| + | |||

| + | Today a quick lab test of the ability of the enabled SPREAD variable calculation to discern between valid data-points and the no-signal "300 mm/s line" will be determined. First it is important to capture some no-single data. To achieve this I set SWEEP_START = 300 and SWEEP_LENGTH = 2000 and kept a clearance of 2500 mm in front of the sensor. | ||

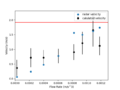

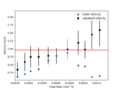

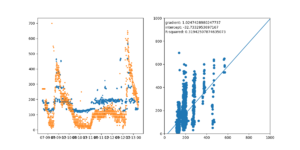

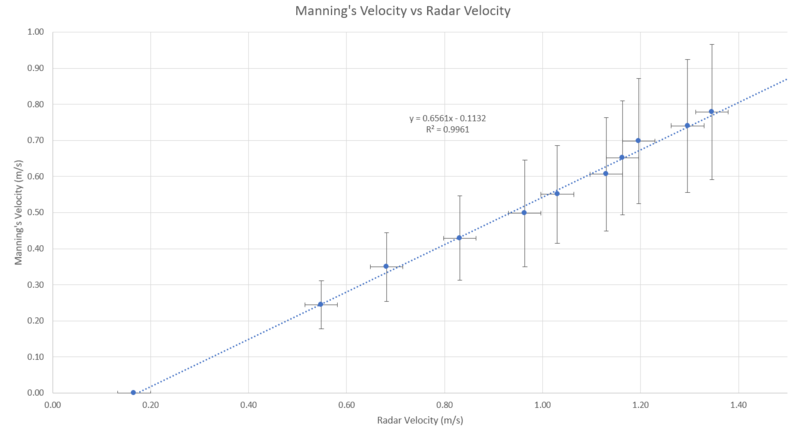

| + | |||

| + | Doing this gave distance velocity plots all similar to the example in the gallery. As seen, the signal looks fairly uniformly distributed throughout the whole plot (the right half of the plot is contained the time series data before the FFT. After the FFT only the left half of the plot contains all the data). Statistics were collected on the VEL, DIST, AMP, and SPREAD variables in the no-signal measurement and given in the table below. These statistics give us some interesting findings: 1) the standard deviation on VEL is quite tight when there is no-signal, only 5mm/s. Therefore, assuming the data is normally distributed, we can expect only 0.3% of the no-signal velocity readings to lie outside the range (286,316). Next we note that the DIST has a large standard deviation, this fact is difficult to use when determining if a single point is no-signal, however could be more useful if a timeseries is available. AMP also has a small standard deviation, however I am not sure how this compares to when a strong signal is present and so not much can be said of this right now. Finally we have SPEAD, which again has a large standard deviation and is unfortunately not constricted to a narrow range of values however, we need to await the strong-signal data to see how SPREAD differs. | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! !! colspan="2"| no-signal (N = 354) !! colspan="2"| static-signal (N = 165) !! colspan="2"| reflector-signal (N = 41) | ||

| + | |||

| + | |- | ||

| + | ! variable !! mean, µ !! standard deviation, σ !! mean, µ !! standard deviation, σ !! mean, µ !! standard deviation, σ | ||

| + | |- | ||

| + | | VEL (mm/s) || 301 || 5 || 286 || 7 || 167 || 105 | ||

| + | |- | ||

| + | | DIST (mm) || 1345 || 370 || 970 || 133 || 1708 || 276 | ||

| + | |- | ||

| + | | AMP (arb) || 2.15 || 0.21 || 3.05 || 0.87 || 13.40 || 12.28 | ||

| + | |- | ||

| + | | SPREAD (arb) || 253 || 69 || 232 || 72 || 85 || 130 | ||

| + | |} | ||

| + | <gallery> | ||

| + | No-signal-DV-plot.png | No-signal distance velocity plot. | ||

| + | Static-signal-DV-plot.png | Static-signal distance velocity plot. | ||

| + | Reflector-signal-DV-plot.png | Reflector-single distance velocity plot. | ||

| + | </gallery> | ||

| + | |||

| + | Next it is important to look at the situation where we have a direct static reflector in front of the radar sensor. This will likely change AMP, but hopefully DIST or SPREAD may be used now to discern the low-signal regime. | ||

| + | |||

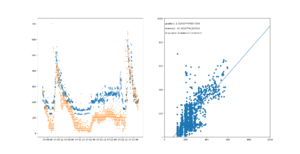

| + | I have now collected some data in the static-signal regime. This data has been collected by placing a static reflector approximately 1000 mm from the radar sensor. The idea here is to model the signal in dry-weather where the dominant signal is coming from the bottom of the channel. As seen from the plot in the gallery, this situation visually looks similar to the no-signal situation except that there is one row which has a higher signal strength, particularly so at low velocities (left hand side of the plot). From the statistics we note that mean of VEL has decreased significantly, and the standard deviation has increased. Taken together the low-signal data is no longer confined to such a tight VEL range and may extend down to 265 mm/s instead of 286 mm/s. As expected for a static reflector we are getting a defined DIST measurement, though the standard deviation here is still quite large (so it is not sufficient to filter based on DIST being equal to a particular number ie: the height of the sensor). The AMP variable has an increased µ and σ, however it is unclear if the statistics of AMP will remain the same when a genuine signal is present. SPREAD has only a slight change to µ and σ, and likewise it is unclear if it will change in the presence of a genuine signal. | ||

| + | |||

| + | Next I moved a static reflector slowly (100s mm/s) perpendicular to the radar sensor (ie: keeping the same distance). This is not a completely accurate representation of water flow (it is probably much higher in signal strength) however it is a moving object, which distinguishes it from the previous two cases. When I have access to a flume, I can collect more data on how real water flows behave. It is obvious from the relfector-signal plot that the signal is highly localised both in velocity and more so in distance. In the statistics we now see that VEL has a different mean, a good indicator that the reflector was moving. DIST is very context dependant for a real signal. The mean AMP is now much greater > 10. It has high variance however, and its range overlaps with the low-signal trails. SPREAD has a significantly lower mean (~90 vs ~ 250), yet its standard deviation is also high and some of the valid data points have a SPREAD comparable with those of the low-signal data. One cavate of the reflector-signal dataset is that as the reflector was moved back and forth, I can't be confident that a) it was in the field of view of the radar detector at all times, and b) was moving while the measurement was occuring. Hence, it may be possible that some of the reflector-signal data actually are actually not measuring anything. This issue will be resolved when I perform the flume testing. | ||

| + | |||

| + | == 2nd July 2024 == | ||

| + | |||

| + | A critical bug was fixed in the calculation of the angle corrected velocity. The incorrected /sin calculation was modified to the correct *sin. This has been released in radar firmware rev 1.8.2. | ||

Latest revision as of 23:52, 21 December 2024

SUMMARY

Check out the full paper: https://doi.org/10.3390/s23146314

Extended abstract submitted to SPN2022: File:BoSL Radar sensor extended abstract.pdf

For instructions on how to assemble the sensor please see the wiki page Assembling the Radar Sensor

For information on how to use the velocity sensor please see the getting started page Getting Started With the Radar Sensor

Contents

- 1 27th January 2021

- 2 28th January 2021

- 3 2nd February 2021

- 4 5th February 2021

- 5 8th February 2021

- 6 9th February 2021

- 7 10th Februrary 2021

- 8 11th Februrary 2021

- 9 12th February 2021

- 10 15th February 2021

- 11 17th February 2021

- 12 25th February 2021

- 13 28th February 2021

- 14 7th March 2021

- 15 24th March 2021

- 16 4th April 2021

- 17 27 May 2021

- 18 29th June 2021

- 19 30th June 2021

- 20 2nd July 2021

- 21 5th July 2021

- 22 7th July 2021

- 23 22nd July 2021

- 24 29th July 2021

- 25 5th August 2021

- 26 15th August 2021

- 27 19th August 2021

- 28 26th August 2021

- 29 27th August 2021

- 30 7th September 2021

- 31 8th September 2021

- 32 23rd September 2021

- 33 29th September 2021

- 34 7th October 2021

- 35 21st October 2021

- 36 26th October 2021

- 37 28th October 2021

- 38 6th November 2021

- 39 15th November 2021

- 40 22nd November 2021

- 41 23rd November 2021

- 42 24th November 2021

- 43 29th November 2021

- 44 30th November 2021

- 45 3rd December 2021

- 46 6th December 2021

- 47 7th December 2021

- 48 8th December 2021

- 49 9th December 2021

- 50 10th December 2021

- 51 22nd December 2021

- 52 14 January 2022

- 53 15th February 2022

- 54 16th February 2022

- 55 17th February 2022

- 56 22nd February 2022

- 57 23rd February 2022

- 58 27th February 2022

- 59 1st March 2022

- 60 5th April 2022

- 61 6th April 2022

- 62 13th April 2022

- 63 27th April 2022

- 64 5th May 2022

- 65 11th May 2022

- 66 19th June 2022

- 67 20th June 2022

- 68 5th September 2022

- 69 6th September 2022

- 70 8th September 2022

- 71 9th September 2022

- 72 12th September 2022

- 73 24th October 2022

- 74 16th November 2022

- 75 21st November 2022

- 76 30th January 2022

- 77 3rd February 2022

- 78 6th February 2022

- 79 9th May 2024

- 80 20th May 2024

- 81 2nd July 2024

27th January 2021

We have ordered some radar sensors from Acconneer, namely the A111, in the XM132, and XE132. And some radar lenses for these.

The XE132 from acconeer comes with pre-compiled binary software, that allow it to connect via micro USB to a computer and create visualizations of the data.

The XE132 was set up as per the user guide, as was the Acconneer portable exploration tool.

Of interest to our application is the sparse short-time FFT visualisation as it allows the speed to be determined at different distances from the sensor. As can be seen from the gallery there is an FFT for each of the 6cm distant ranges, a matrix plot of the velocity-speed readout of the sensor.

Open question which need to be answered for this sensor are of question of how the lens impacts performance, if the Doppler shift of water can be measured, and at what angle to the flow is the Doppler shift successfully measured.

28th January 2021

Today we will test the XE132 in the flume. Just a basic test will be conducted. The radar sensor will be pointed at the flume surface and the short time fft visualization tool will be used to detect if a Doppler shift if present. Different angles and lens configurations will be tested.

It was found that the water velocity was not able to be easily seen with the acconneer radar sensor. It seem that the issue being had is that there is little reflection off the water surface. A wide range of angles were tested. Specifically the velocity was not seen to go above about 0.1 m/s. This was not easily separable from errors such as the water surface level changes.

Following some more tests in the flume it was seen that the high velocity readouts occurred when the water velocity was greatest, hence adding to the hypothesis that the changes in surface height were being measured more than the water velocity itself.

In another test outside the flume, the radar sensor was moved at an angle to the floor and at a constant height. At a 45 degree angle it was seen that the Doppler shift was able to be measured, however with a weak signal, as the angle decreases this signal became stronger in amplitude but the measured velocity decreased until when the radar was pointed vertically, no horizontal movement would cause Doppler shift. This test highlights that a good reflected signal occurs perpendicular to the surface, but a good Doppler shift occurs parallel to the surface.

If this system is going to function, it is needed to test how to achieve a better reflection of water and how to minimise the effect of water surface changes.

In investigating other high cost Doppler radar sensors, they all seem to require a minimum surface ripple height of about 3mm. I have a suspicion that this is because the reflect the Doppler signal off the rising slope of the wave, hence getting a good reflection angle to bounce the signal back to the sensor. These sensors are also quoted as measuring the surface velocity, which further supports this. https://www.mdpi.com/2072-4292/12/8/1296/htm discusses this listing the small surface waves as scatterers. That paper also predicts the optimal size for a 60GHz surface scatterer wave is 3mm. In reflecting on the flume experiment, it the flow was very smooth at some parts, the lack of reading is not explained with the above information.

2nd February 2021

The acconneer XE132 was tested along with the lens kit. With was done in a bath tub filled with water. The aim of the test was to see if the acconeer was able to measure the velocity of waves generated in the tub. To do this a cylindrical object was bobbed up and down propagating out waves which would then travel under the acconeer's measurement zone. The acconeer was mounted about half a meter above the waters surface, and angled at about a 45 degree angle. Hence the water surface was on the order of 1 meter away from the sensor. The results were monitored on an external computer via acconeer's portable exploration tool.

The short time fft measurement tool was used and it was found that the water waves were able to be measured. The waved needed to be of a sufficient size in order for them to be detected, a few millimetres in size as predicted by theory was found to be about right, surface bubbles or other small surface features greatly helped the sensor detect a stronger return signal.

The settings were then optimized, to get the best performance. This was found to be when:

- Range Interval - set as appropriate

- Profile - 3

- Sweep Rate - 2000 Hz

- Sweeps per frame - 32

- Sampling Mode - A (less correlation)

- Repetition Mode - Host Driven

- Down sampling factor - 1

- HW accel. average samples - 32

- Gain - 0.5

5th February 2021

Today was spent developing a testing device to further and numerically verify the performance of the radar sensor. It is a PVC pipe with an attachment point for the radar velocity sensor. This attachment point can vary the sensors height and angle above the water surface allowing the testing of these different parameters. The water will be sent down the PVC pipe where the angle of the pipe can be changed to allow different water velocities. Area in which this test environment is more challenging that an actual installation is that the PVC pipe is a very narrow water stream hence the radar reflection area is much smaller than in a more natural stream.

Images of the test platform can be seen below.

An endcap is attached to the far end of the pipe via duct tape this allows water to build up and increase the water surface height, hence also altering the velocity. The radar velocity sensor screws into the front of the attachment point.

The amount of metal in the design was reduced as metallic object might interfere with the radar beam.

8th February 2021

The apparatus built above was used to test the radar sensor. To do this the radar sensor was attached 800 mm above the pipe and angled at a 45 deg angle of declination. The pipe was inclined at an angle no greater than 5 deg. A hose pipe was used to flow water down the tube. The radar setting were as described above. Initially this didn't work with no reading being detected.

A jet setting was then used on the hosepipe to shoot water just above the pipe. This was able to be detected by the radar sensor with a velocity of about 1 m/s. Again, when this was done just inside the pipe, no reading was given. This indicates that the pipe adds too much attenuation to the signal.

The radar sensor was then lowered to 400 mm and angled at 45 deg. This time it was able to get a reading when there was flow in the pipe. This confirms that the attenuation was too high previously. In a real application it is hoped that the lack of the PVC cover and the wider width of the water surface will provide enough more signal for a reading to still be achieved. It should be noted that a wide surface helps significantly with falloff as point objects falloff with 1/r^4 and planar objects 1/r^2.

In a rudimentary test, the height of the pipe was increased and the water velocity was also seen to increase. Now a more detailed experiment will be undertaken mostly to determine the linearity of this device.

For the experiment some changes had to be made to the PC host. This was to get some form of averaging on the output as this fluctuated frequently. The way this was done is by taking the past N = 20 FFT frames and averaging these. The FFT frames are the arrays of speed vs distance. From this the average distance and speed coordinate from measurements at least half of the maximum was found and printed to the terminal. This will serve as the measured data for the experiment.

A hosepipe was used to send water down the pipe. The height of the far end of the pipe was changed to get different angle measurements. water was injected at approximately the point directly below the sensor.

The results of the experiment are included below:

| Pipe Height Top (H)(mm) | ΔH (mm) | Velocity (v)(m/s) | Δv (m/s) |

|---|---|---|---|

| 0 | 20 | 0.17 | 0.03 |

| 100 | 20 | 0.66 | 0.02 |

| 200 | 20 | 0.79 | 0.02 |

| 300 | 20 | 0.89 | 0.02 |

| 410 | 20 | 0.96 | 0.02 |

| 610 | 20 | 1.13 | 0.02 |

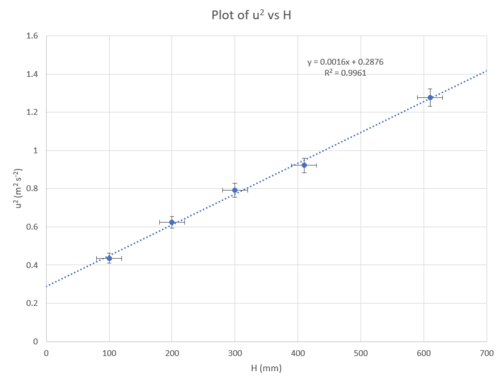

To analyse these data we will apply Bernoulli's principal, thus we will assume our flow is steady and viscous forces are negligible.

We will assume water is injected at the top of the pipe with some initial velocity v, and that as the water runs down the pipe its velocity increases. At the point of measurement by the radar sensor its velocity is u.

As the pipe is inclined there is a height difference between the top of the pipe and the measurement point Δz. We assume that that any pressure gradients are negligible, hence

1/2 ρ u^2 = 1/2 ρ v^2 + ρg Δz

u^2 = v^2 + 2ρgΔz

Furthermore some geometry reveals that the height difference Δz is proportional to H, the height of the top of the pipe. Hence κH = Δz for some κ.

Finally this gives: u^2 = 2ρgκH + v^2.

Thus a plot of u^2 vs H should provide a linear plot. It should be noted that the radar velocity sensor does not measure u, but infact u*cos(θ), where θ is the angle of the sensor from the water velocity in our case this is 45 deg, and constant, hence this conversion factor can be ignored.

Doing this we get the plot below. Note the zero height data-point was excluded from analysis. As I'm not as confident that the approximation made fit at this regime.

The plot indicates that the trend is fairly linear with an R^2 value of 0.996. The line of best fit also lies within the uncertainty of the data points. It indicates that the sensor does indeed make linear measurements of water velocity in the right conditions. What this experiment does not tell us is if absolute measurement is correct or of a linear calibration will need to be conducted. It does also not let us know what errors we should expect from the difference between water surface velocity and mean water velocity.

9th February 2021

In the work so far a radar lens was critical to the performance and focusing of the radar sensor. In any future design it will be necessary to have a lens present. 3D printing the lens is feasible as the mm waves are long relative to the minimum feature size of the 3d printer and geometric optics can be used as the waves are short relative to the size of the lenses. Measuring and characterizing materials at 60 GHz to make accurate calculations of the of the performance of lens is out of the scope of equipment at hand. Instead a empirical approach will be taken. A number of lenses will be designed and they will be tested at a set of different distances from the sensor. The one which performs optimally will be chosen for the design.

To do this both the lenses and a jig will need to be designed which is able to hold different lenses and different distances from the radar sensor. For this a simple block of wood with a grove cut out in it was made. Adding some blu-tack into the groove allows a bit of z-positioning for alignment of the optical axis. Lenses can be rested on the surface of the wood. Their size is such that when resting on the block they are approximately aligned with the optical axis.

In terms of the different lenses designed a variety designs were modded. The use of Fresnel lens was considered however it was found that diffractive effects would become prevalent if this was incorporated [1]. A Fresnel zone plate could also be considered however this is required to be made of metal, perhaps PCB printing will be an effective option for this however for the moment it won't be investigated.

The array of lens designs chosen were:

- A copy of the acnoneer Hyperbolic lens

- Hyperbolic lens scaled by 1.5

- 24 mm radius lens with surfaces on front and back (may be tricky to print)

- The 24 mm radius lens with front and back surfaces printed seperately

- 30 mm radius lens

- 30 mm radius lens (no holder to attach to back of previous)

- 30 mm radius lens with larger optical diameter

- 2 step Fresnel version of previous

- 4 step Fresnel version of previous.

In a second task the optimum angle for the radar sensor is to be considered. Previously 45 degrees had been used however this was chosen just for the convenience of setup. There are a number of factors which influence the optimum operation angle. 1. The lower the angle the short the return signal path is, hence getting a stronger return. 2. The lower the angle the less scatter is needed for it to be reflected back to the sensor. 3. The higher the angle the more parallel the water velocity and reflected signals are, hence the larger the cos θ term in the doppler shift equation. This gives better velocity resolution.

To test out the optimum angle the PVC tube device will again be used. Water fill be flowed down the pipe and the velocity will be measured by the velocity sensor. Different angled will be used and the recorded speed, distance, and amplitude of the maximum will be recorded. The pipe will be leveled flat with a spirit level to mitigate the affect of gravity on the speed of flow, and create a more uniform flow field. The radar sensor was 400 mm above the water with the hyperbolic lens, settings for measurement were as above except where otherwise noted.

The data obtained was

| Angle of declination (deg) | Speed (m/s) | Distance (cm) | Amplitude (arb) | Speed/cos(θ) (m/s) |

|---|---|---|---|---|

| 0 | 1.26 | 57 | 600 | 1.26 |

| 23 | 1.28 | 57 | 600 | 1.39 |

| 40 | 1.26 | 70 | 1000 | 1.64 |

| 53 | 0.13 | 53 | 2000 | 0.22 |

| 66 | 0.13 | 46 | 4000 | 0.32 |

| 90 | 0.11 | 43 | 13000 | inf |

It should be noted that a signal of 600 is approximately the background noise at these settings, 1.26 m/s and 57 cm are the center of the measurement range and so likely a null reading.

The speed of 0.13 is only 1 above the reading of zero, it was found that more resolution was needed to resolve these points so the sweep rate was decreased to 500 hz. Doing this obtained the data:

| Angle of declination (deg) | Speed (m/s) | Distance (cm) | Amplitude (arb) | Speed/cos(θ) (m/s) |

|---|---|---|---|---|

| 0 | 0.01 | 37 | 900 | 0.01 |

| 23 | 0.01 | 37 | 900 | 0.01 |

| 40 | 0.08 | 56 | 950 | 0.10 |

| 53 | 0.10 | 53 | 1500 | 0.17 |

| 66 | 0.05 | 45 | 3000 | 0.12 |

| 90 | 0.04 | 43 | 25000 | inf |

I still was't satisfied with the performance of the sensor at this point, particularly the quantisation of the speed at low velocities. Some setting were adjusted to be:

- Range Interval: 0.24 - 0.8 m

- Profile: 3

- Sweep Rate: 500 Hz

- Sweeps per Frame: 64

- Sampling Mode: A

- Repetition Mode: Host Driven

- Downsampling Factor: 1

- HW accel average samples: 32

- Gain: 0.5

- Power Saving Mode: Active

- Enable Asynchronous Measurement: True

With these settings the data obtained was:

| Angle of declination (deg) | Speed (m/s) | Distance (cm) | Amplitude (arb) | Speed/cos(θ) (m/s) |

|---|---|---|---|---|

| 40 | 0.15 | 60 | 1600 | 0.19 |

| 53 | 0.10 | 53 | 2400 | 0.17 |

| 66 | 0.04 | 45 | 4500 | 0.10 |

| 90 | 0.025 | 42 | 64000 | inf |

While the results are not definitely conclusive as to a best angle which can be chosen, it appears that generally the correction of cos(θ) works when the measured velocity isn't too small, or the angle too steep, this is important as it means that the water velocity recorded is more due to the propagation along the flow lines rather than change in the water surface height due to waves etc. It also appears in the data that angles too steep or too shallow cause problems with either no signal being obtained or no velocity data in that signal. An angle of declination somewhere between 40 - 65 degrees seems appropriate. A note that in the final design we should include an accelorometer to measure the angle without user input.

10th Februrary 2021

A useful resource with documents requirements for radar installation: https://my.usgs.gov/confluence/display/SurfBoard/Guidelines+for+Siting+and+Operating+Surface-water+Velocity+Radars This website is helpful in the listings of material properties at 60 GHz, https://www.infineon.com/dgdl/Infineon-Radar_wave_propagation_through_materials-Whitepaper-v01_00-EN.pdf?fileId=5546d462766cbe8601768a120c6d36cf&da=t

Using the infineon document an ehstimation of the losses due to the presence of the PVC pipe in the tests above can be calculated. Tables 2 and 3 give the surface and volume attentions due to various materials of 60 GHz, using figure 3, it is seen that the the angle of 45 degree inclination can be largely ignored as it does not have a significant impact for the estimation. The double pass surface attentation is ranging from -1.34 (Plexiglass) to -2.59 (nylon). The volume attenuation for 4 mm of PVC (double pass) is ranging from -0.44 (polycarbonate) to -8.64 (nylon). This gives a total transmittance range of 60% to 8% hence it is likely that the PVC pipe caused a reduction in the radar power of at least one half.

11th Februrary 2021

Today we will be testing out the various lenses printed yesterday. To start with the lens block will be fixed in place with some blutack and the XE132 inserted into the cutout grove. The lens block needed to be raised off the table with a plastic container as the surface of the table is metal and this interferes heavily with 60 GHz radar. In the portable exploration tool the power bins tool was used. The lab environment was likely a poor choice of location do to this experiment as there were many obstacles which the radar could reflect off. This issue was found to be too challenging to combat and it was thought that better results could be attained by relocating the experiment.

The experiment was then moved to a room with fewer obstructions. A whiteboard of several meters squared in area of positioned about 5 meters from the radar sensor and lens holder which were fixed atop a table such that and such that their height was approximately the same as the center of the whiteboard. Again the same radar settings were used in the exploration tool.

Some notes while conducting the experiment were that the lenses were difficult to position on and keep stable, this resulted in high uncertainty in the data collected. A better system will need to be designed for the final product and for more finalized testing. Factors such as angle and lateral positioning were seen to play a large role in the reading received. Also notable is that the reading tended to oscillate up and down with a period of a few millimetres when altering the distance of the lenses.

The specific settings used for the potable exploration tool were:

- Bin Count: 7

- Range Interval: 2 - 7 m

- Profile: 4

- Update Rate: Limit 50 Hz

- Repetition Mode: Host Driven

- Downsampling Factor: 4

- HW accel average samples: 10

- Gain: 0.5

- Power Saving Mode: Active

- Enable Asynchronous Measurement: True

In the data the amplitude measurement was taken as the amplitude in bin 5. The distance measurement was the distance from the base PCB of the XE132 to the back surface of the lens, note that the base PCB is attached to the XM132 PCB to which the A111 is mounted.

The data taken is included in the table below:

| Lens | Distance (mm) | Amp (arb.) | Gain (dBFS) | Angle subtended by lens (deg) | |

|---|---|---|---|---|---|

| none | 600 | 0 | |||

| ACC-HPL | 8.2 | 4000 | 16.5 | 70 | |

| ACC-FZP | 22 | 2000 | 10.4 | ||

| ACC-COV | 25 | 1000 | 4.4 | ||

| PLA_1 | 37 | 3200 | 14.5 | 39 | |

| PLA_2 | 34 | 3800 | 16 | 41 | |

| PLA_3 | 14 | 5000 | 18.4 | 64 | |

| PLA_4 | 8.2 | 4200 | 16.9 | 70 | |

| PLA_5 | 25 | 3000 | 10.4 | 41 | |

| PLA_6 | 38 | 7000 | 21.3 | 52 | |

| PLA_7 | 29 | 6000 | 20 | 52 | |

| PLA_8 | 17 | 2600 | 12.7 | 52 |

The lens names for in the above table can be referenced to:

| Name | Material | Infill(%) | Radius Front (mm) | Radius Back (mm) | Aperture (mm) | Notes |

|---|---|---|---|---|---|---|

| ACC-HPL | PA-12 | 100 | 12 | inf | 22 | |

| ACC-FZP | PA-12 | 100 | ||||

| ACC-COV | PA-12 | 100 | ||||

| PLA_1 | PLA | 95 | 24 | inf | 30 | |

| PLA_2 | PLA | 100 | 24 | inf | 30 | |

| PLA_3 | PLA | 100 | 12 | inf | 30 | |

| PLA_4 | PLA | 100 | 12 | inf | 22 | |

| PLA_5 | PLA | 100 | 12 | 12 | 22 | |

| PLA_6 | PLA | 100 | 30 | inf | 49 | |

| PLA_7 | PLA | 100 | 30 | inf | 49 | 2-step Fresnel |

| PLA_8 | PLA | 100 | 30 | inf | 49 | 4-step Frenel |

Firstly to note that Acconeer specifies the gain of the ACC-HPL at 8.2 mm as 17.3 dBFS which is somewhat similar to the value of 16.5 dBFS measured here. We can see that the performance of the best lens the PLA_6 had a performance of 21.3 dBFS. This lens design will be used in the final product. Also interesting is determining the focal length of the lenses as this can be used to estimate the refractive index of the the PLA plastic used. If we assume that the focal length is the distance at which maximum power was achieved (This can be justified as 5 m is very far relative to the other distances in the problem and hence can be treated at infinity) then we can apply the lens makers formula to get the refractive index. When this is done a value of between 1.7 and 2.0 is given. For the purpose of future design a value of 1.8 will be used however it will be noted that this can be used for rough calculation only, and final design will need to be verified via experiment. The calculated angle subtended by lens is useful as it gives some indication of how much of the radar output is being "picked up" by the lens. Note that acconeer specifies that the half power beam width is 40 deg in the E-plane and 80-deg in the H-plane.

12th February 2021

At 10 GHz this paper: https://ieeexplore.ieee.org/document/7535340 finds that the refractive index of PLA is about 1.85. Another consideration for lens design is that it should preferably a multiple of λ/2 away from the sensor, this minimizes destructive interference. The A111 has a specified center frequency of 60.5 GHz, hence giving a wavelength of 4.96 mm. Thus the focal point of our lens should be some multiple of this. We will go for a lens most similar to PLA_6, hence the r_f ~ 30 mm and r_b ~ inf. Thus the lens makers formula gives: 1/f = (n-1) 1/r_f. Since f = mλ/2, then: r_f = m(n-1)λ/2. We will use a PLA refractive index of 1.85, hence, the closest focal lengths available are m = 15: r_f = 31.6 mm and f = 37.2 and m = 14: r_f = 29.5 mm and f = 34.7

As there is still some uncertainty in this calculation, a number of lenses close to these values should be built and evaluated experimentally to see which gives the best performance.

15th February 2021

The flow measuring experiment was rerun, this time with a few improvements. The analysis this time will be using manning equation as this provide an estimation of the velocity rather than relying on just relative measurements from Bernoulli. A few modifications were made to the pipe apparatus. Firstly a stand was constructed so now the start of the pipe could be positioned in heights of 50 mm increments. A sponge was also inserted into the start of the pipe to make the flow more consistent.

First the flow rate was measured. This was found to be 60 mL/s. The pipe was then placed on a level surface, as measured with a spirit level. At this height the stand was at its "0mm" setting. The radar sensor was placed at 400 mm above the pipe at an angle of declination of 53 deg.

The sponge had to be removed as when it was present no water velocity could be measured. This is likely something to do with the removal of scatters that is created.

The stand of the pipe was used to set the pipe to a given height. The water was then turned on and allowed to flow down the pipe, after a few tens of seconds the acconeer portable exploration tool on the settings shown below, was used to measure the water velocity, distance to water surface, and amplitude of the signal. A ruler was then used to measure the width of the water flow at the far end of the pipe. These data were recorded in a table and then the height was changed to proceed to the next data point.

It is noted that the some difficulty was had to measure the the width of the water flow, this is because the width only changed slightly through the experiment and the edges of the flow become hard to determine to a high precision. This also had to be measured at the far end of the pipe away from the center, where the measurement was occurring, due to the need of visual access for the ruler.

Aconneer Settings:

- Range Interval: 0.24 - 0.8 m

- Profile: 3

- Sweep Rate: 500 Hz (1000 Hz for height 200 mm and higher)

- Sweeps per Frame: 64

- Sampling Mode: A

- Repetition Mode: Host Driven

- Downsampling Factor: 1

- HW accel average samples: 32

- Gain: 0.5

- Power Saving Mode: Active

- Enable Asynchronous Measurement: True

The data obtained is recorded in the table below:

| Height (mm) | Velocity (m/s) | Distance (cm) | Amplitude (arb) | Flow Width (mm) | Velocity/cos Θ (m/s) | Slope (m/m) | Hydraulic Radius (mm) | Manning's Velocity (m/s) |

|---|---|---|---|---|---|---|---|---|

| 0 | 0.10 | 51 | 2700 | 60 | 0.17 | 0 | 47 | 0.00 |

| 50 | 0.33 | 54 | 10000 | 45 | 0.55 | 0.03 | 49 | 0.24 |

| 100 | 0.41 | 54 | 12000 | 37 | 0.68 | 0.07 | 50 | 0.35 |

| 150 | 0.50 | 55 | 10000 | 35 | 0.83 | 0.10 | 50 | 0.43 |

| 200 | 0.58 | 55 | 6800 | 30 | 0.96 | 0.13 | 50 | 0.50 |

| 250 | 0.62 | 55 | 11000 | 40 | 1.03 | 0.17 | 50 | 0.55 |

| 300 | 0.68 | 55 | 10000 | 36 | 1.13 | 0.20 | 50 | 0.61 |

| 350 | 0.70 | 55 | 9800 | 40 | 1.16 | 0.23 | 50 | 0.65 |

| 400 | 0.72 | 55 | 9000 | 38 | 1.20 | 0.27 | 50 | 0.70 |

| 450 | 0.78 | 56 | 7500 | 38 | 1.30 | 0.30 | 50 | 0.74 |

| 500 | 0.81 | 56 | 7200 | 40 | 1.35 | 0.33 | 50 | 0.78 |

Some other measurements about the setup were that the length of the pipe was 1500 mm, and its diameter 103 mm. From this the slope can be calculated as h/length, and the Hydraulic radius can also be calulated noting that the cross section of the pipe is a circle. Manning's equation can be applied to get the manning velocity, this requires a manning coefficient, this can be looked up to be roughly 0.01 as the pipe was made of PVC.

The uncertainties involved can be estimated as the following: Height - 5mm, Velocity - 0.02 m/s, Flow Width - 5mm, Pipe Length - 10 mm, Pipe radius 1 mm. From these the uncertainties in other quantities can be derived. The Manning's Roughness obviously had uncertainty however this will be excluded from the numeric analysis initially.

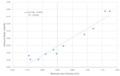

A graph can be drawn comparing the manning velocity to the measured velocity this is done below:

The graph shows that there exists a strong linear correlation between the manning velocity and the radar velocity with an R^2 value of 0.996. The gradient of the plot and its y-intercept are not 1 and 0 respectively. It is possible that the error in the gradient is due to the uncertainty in the Manning's roughness, as it is possible that the value found from a lookup table was off by some amount, and it is also the case that the Manning's roughness would directly alter the gradient of the graph. The non-zero y-intercept could be because the flow isn't entirely driven by gravity by also the water pressure from the water source.

Overall this experiment gives me confidence that a implementation of this radar velocity system will work well at measuring the water velocity, perhaps requiring a linear calibration to achieve grater accuracy.

17th February 2021

Today was spent porting over functionality of the acconeer portable exploration tool to a python script. The python script will directly control the registers of the XM132 hence this code becomes easily integrate-able into a future design. The reason this was first done in python is that it is much quicker to debug if something isn't working quite right. Details of the registers are found from documents on acconeer's website.

25th February 2021

More work was done porting over the processing algorithm. Specifically, work was done to take the python algorithm developed and rewrite this into c++ code which can be uploaded to the chosen microprocessor. The microprocessor to be used has not be chosen yet so the code cannot be specialized, however general algorithmic functions are still able to be implemented. One major consideration is memory usage, if the chosen processor is the ATmega328p then memory will be quite tight, and so the program is being optimized to minimize this usage. The same modified library for FFT calculations used in the in water velocity sensor is being used since it fulfills the same design requirements. Of course the discreet Harley Transform is always very appealing due its its more efficient operation and memory usage however, its difficult to find an efficient implementation for Arduino and well optimized FFT would still be faster.

Some notes about the program is that it current takes the FFT over a large set of distances, to get a distance-velocity matrix. There could be another possible method which would achieve higher distance accuracy and less memory usage. This would involve fist using a distance optimized service on the A111 to get the water distance within some millimetres, and then using this distance to the water surface to set the A111 sparse service used for doppler measurement to measure only at this distance. This would compress the 2D distance-velocity matrix to 1D only velocity array and so save substantial memory. The downside of this approach however is that it would likely take more time to make a measurement, code would need to be written to detect a reflection off water from the distance service, and this information would then need to be given to the sparce service. Giving a inaccurate distance measurement could mean that no velocity data is obtained when in fact the water is flowing.

28th February 2021

Some reading was done into the ideal processor for the radar velocity sensor. Memory permitting a good option would be an ATmega328PB, this is like the ATmega328P however has two serial ports, this is useful as we would need one serial port for communication with the BoSL and one for communication with the XM132 module. It is also familar being able to use all the familiar tools. If memory does not permit then it looks like the SAMD21G would again be a good choice. After completing the code it looks at if the maximum number of memory needed will be less than 2K. This is because the XM132 does not like to go above 64 sweeps per frame, so even with 7 range bins this is approx 1.2K including auxiliary memory needed for data processing.

We will now begin work on the hardware integration.

7th March 2021

More work was done on designing a board for the radar sensor. The basic design was an ATmega328PB and the XM132. These communicate via a serial connection. The XM132 is connected through a load switch and tri-state buffer, this allows it to be entirely turned off when not in use, lowering quiescent current. We have additionally exposed the XM132 SWD interface and a communication/programming interface for the ATmega.

An accelomometer will be included to determine the orientation of the sensor, this is necessary to determine coefficients in the dopper shift and distance calulations. The chosen accelorometer is will be the KXTJ3-1057.

24th March 2021

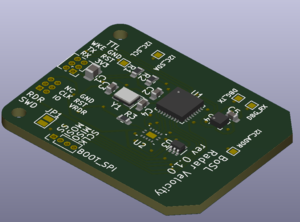

The final checks were conducted on the schematic. A bill of material was made for the device with total cost coming to around $25 USD. A few adjustment had to be made in the part list due to stock shortages. Mounting holes were added to the PCB to aid in the designing of the case. I have put in two screw holes with the idea that the other side can be secured with a ledge from the casing.

4th April 2021

Silkscreen detailed were added to the PCB and the schematic was double checked against the datasheets. A prototype design (rev 0.1.0) of the PCB was sent off for printing. The design files can be found at the design library .

27 May 2021

We got the radar PCB's back however there was a light issue with the buffer-gate footprint. This was removed and the relevant pads were shorted.

The minicore ATmega328PB bootloader was able to be uploaded and then the device could be used as expected.

There exists another issue with the radar power regulator, it turned on far too fast for the circuit, that is that it causes a brownout condition when it turned on. For now we can just supply 3V3 volts to the VRDR. For the future there exists a version of the the power switch used with a soft start.

After JP1 was bridged closed the ATmega328p could talk to the XM132 module.

The XM132 firmware was flashed over SWD.

To do this first the SWD header was connected to the j-link base and power was supplied to the XM132.

The j-flash lite utility was then used with the STM32G071CB mcu setting to program the firmware binary supplied on the acconeer website.

The offset address is set to 0x08000000 in the j-flash software.

Some debugging was done to the firmware written for the ATmega328PB.

Some work still needs to be done on reading the buffer data. It currently seems to be too fast for the arduino to keep up.

The buffer work was completed, it was actually mostly just buggy code, the current issue is memory. Memory related crashes are causing issues with the sensor. These need to be ironed out.

These were ironed out and now we are getting velocity and distance readings which are fairly close as when compared to the same data analysed in python.

We now move on to testing the accelorometer.

It was found possible to get the accelorometer working, and easy to get the declination angle out afterwards.

All the parts have been verified working and are able to be integrated together in one firmware.

29th June 2021

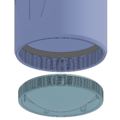

A case for the Radar sensor is being designed. The case needs to host the lens and the radar PCB. The below design was used a first prototype:

30th June 2021

The radar was placed in its enclosure and tests were conducted to determine the radar performance and to check if any of the enclosure would inhibit the radiation power and range of the device.

To do this the radar module was firmly fixed in place and pointed at a metal screen about 3 meters from a large metal screen. The following code was then uploaded to the module: File:Radar velocity pwr test.zip file attach and the module was connected to a computer via a serial port. The python script File:XM132serial livepwr.zip, was then used to analyse the data coming back. This data was a measurement of the reflected power in 1 m bin increments away from the sensor. The average over time of the bin at 3 meters was then recorded with different lens setups.

Case number 3 and radar module 001 and the 30 mm radius lens were used. The lens was positioned at different distances from the lens stop on the case via plastic shims of know thickness.

The results are below:

| Distance (mm) | Power (arb.) |

|---|---|

| no lens | 12300 |

| 0 | 20800 |

| 1 | 21000 |

| 2 | 21000 |

| 3 | 21100 |

| 4 | 20700 |

| 5 | 20900 |

| 6 | 21000 |

| 7 | 21000 |

as is seen the presence of the lens had a large effect on the reflected power +75%. This is less than seen in previous lens tests were increases of 10x were seen. This could either be due to the radar case affecting performance or the 3 m reflection distance being closer than other tests, and the lens having a greater effect at increasing the reflected power at greater distances.

More tests involving different lenses and case designs should be investigated.

An interesting example how the sensitivity of the radar module to the case was found, putting a 4mm thick 1 mm wide radar lens shim in the case while there was no lens reduced the no lens reflected power by 3000. This indicates that several different radar case designs should be trialed

The test above was repeated with lenses of radius 31 mm and 29 mm however the results were immeasurably different.

2nd July 2021

The test on the 30th of June were repeated for lenses of radius 45mm 40mm 35mm 27.5mm and 25mm. The data is tabulated below,

| Distance (mm) | Power (arb.) | |||||

|---|---|---|---|---|---|---|

| Lens radius: (mm) | no lens | 25 | 27.5 | 35 | 40 | 45 |

| 0 | 11000 | 13200 | 17800 | 20300 | 18600 | 15800 |

| 4 | - | 10400 | 15600 | 20500 | 19300 | 18300 |

| 6 | - | 7600 | 14000 | 20300 | 18600 | 17700 |

The results indicate that lenses of these sizes perform no better than the 30mm lens used previously. Therefore the 30mm lens will be chosen for the design.

5th July 2021

A number of different cases for the radar PCB were tested to see their impact on radar performance. A similar test was used to the power testing on prior days. The results are shown below, a distance '-' indicates no lens was used. Otherwise the 30mm radius lens was used.

| Case number | Distance (mm) | Power (arb.) |

|---|---|---|

| 3 | - | 11500 |

| 3 | 4 | 20800 |

| 4 | - | 4500 |

| 4 | 4 | 20700 |

| 5 | - | 6000 |

| 5 | 4 | 17200 |

| 6 | - | 2700 |

| 6 | 4 | 16600 |

| 7 | - | 2600 |

| 7 | 4 | 19400 |

| none | - | 2000 |

Case number 3 was the case used for the previous testing it features a conical taper from the aperture to the size of the XM132 board.

Case number 4 features no taper at the aperture until halfway down the barrel. It then features a conical taper to the size of the XM132 board.

Case number 5 features a conical taper from the aperture to the size of the A111 radar sensor.

Case number 6 is like number 4 except it has large cutouts in the barrel to reduce to leave only a small section of material for lens support.

Case number 6 is like number 3 except it has large cutouts in the barrel to reduce to leave only a small section of material for lens support.

It was noted that it was difficult to install the radar PCB, and thus case number 5 was significantly misaligned with respect to the center of the A111 center. The data reveals that the tapering cases act to intensity the received power by up to 5 times compared to without any casing. The lens brings this up to 10 times greater. These results are similar to what was measured in February and explain why the tests in may did not see a 10x increase as those in februrary - because the casing which was used in may already had a 5 times gain when compared to the bare sensor.

It is not clear why the pretense of the case taper tends to increase the received radar power. A detailed radiation analysis would be out of the scope of this work. However some suggestions include increase focusing of the radar reflected off the tapered surface.

Case 8 was a tested which is like case 5 but fixes the alignment issues. This gives a with 4mm distant lens a power of about 19500. This is close to case 3. I think for the final design a version of case 8 with a wider aperture will be chosen. As the taper in case 8 allows for better cable management.

7th July 2021

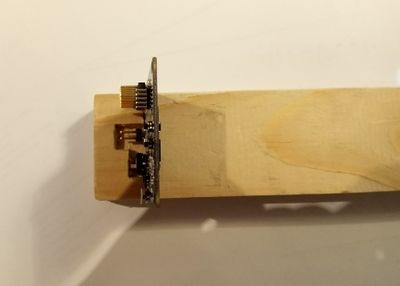

Today a prototype radar sensor was built. This is built into a housing, however is not yet waterproofed. Below are some images which display the sensor.

A stand was also built which holds the sensor. The sensor wiring is detailed in the table below:

| Pin | Colour (ethernet) |

|---|---|

| 3.3 V | Green |

| GND | Half Green |

| Reset | Orange |

| Wake | Half Orange |

| TX | Brown |

| RX | Blue |

22nd July 2021

A quick test was conducted with the PVC pipe to see if the new integrated radar velocity design was able to detect water-flows. The setup was largely the same as in the tests conducted on Feb 15. The data for the two trial was:

| Sensor Distance Above pipe (mm) | Line of sight distance to flow (mm) | Angle relative to flow (deg) | Recorded Amplitude (arb.) | Velocity (angle corrected) (mm/s) | |

|---|---|---|---|---|---|

| Trial 1 | 600 | 1000 | 40 | 120 | 1440 |

| Trial 2 | 1000 | 1200 | 46 | 50 | 1440 |

As is seen the radar velocity sensor is able to measure the flow velocity from two different positions. The distance at which it is measuring these from is greater than when the XM132 module was being used, which was unable to measure flow beyond 400 mm. The signal was quite noisy however, so it is unlikely that the velocity would be able to be recorded from a much greater distance with this setup. Baring in mind that the quantity of flow was small and the radar needed to penetrate through the PCV pipe. The auto-ranging built into the firmware did not function correctly for this experiment. The auto-ranging focused on the distance block which contained the floor, rather than the pipe which was elevated above the floor. This is to be expected as the floor is a much larger reflector. It is hoped that this will not be an issue in common installations where the water channel will be located on the 'floor'. Still it is likely that more work is needed on this auto-ranging system. Regarding the noise of the sensor. It should be investigated how best this can be reduced. With the current flow-level while a prominent peak is seen at the water velocity, other noise associated peaks are seen elsewhere. This will inevitably reduce the accuracy of the sensor as it will sometimes regard one of these noise peaks as the measured velocity.

29th July 2021

The acconeer SDK was downloaded which allows development of applications on the STM32G071 integrated on the XM132. This is useful as we modify the functionality to also perform the majority of the signal processing on the the STM32G071 which is both faster running at 64 MHz, and has much more RAM, 36 kB as opposed to the ATmega 2 kB. This allows much more radar data to be stored and thus processed simultaneously. This is beneficial as it lessens the need to the 500 mm range of interest system, which would have been needed for an implementation entirely on the ATmega (recall that the power bins were first scanned to see which had the greatest reflection) a system like this will no longer be necessary. The first step to getting this working was to mimic the functionality of the acconeer supplied radar module server. In other words writing some code which accepts commands over UART and converts these to actions on the radar module. The set of commands used were identical to those used by the radar module, therefore the software is interchangeable with the software supplied by acconeer (mostly some functions are unimplemented to save on development time).

An issue was encountered that the radar firmware did not allow for arbitrarily long radar sweep lengths. The internal buffer appeared to be limited to 4 kB. This effectively means that the sweep length is capped at 1920 mm. Still a large improvement over the previous 500 mm, however. In addition there remains enough free memory to collate the multiple 1920 mm runs. This is different to what was done with the ATmega as all the data can be processed simultaneously. This system was able to be gotten preliminary working. That is the two services could be set up a measurement made, and then the data could be returned in a contiguous block over serial. This still needs some work, for instance the two data buffers from either service when concatenated are not ordered properly for the current FFT algorithm to work.

5th August 2021

The above work with storing the results in the two arrays was implemented. Indeed it turned out that this was the only way to get the data out, as deactivating a service destroys the data in it. The memory footprint is very mandible for the size of the arrays worked with. Once issue noted was that when started a measurement at a far distance from the sensor >1m the first data point looks low, that is that it looks like it has a very weak reflected signal compared to the other sweeps. Additionally the value it returns stays constant regardless of what is occurring in-front of the sensor. A hypothesis is that the reflected radar signal was not yet reached the sensor at the time this measurement was taken as the radar sensor has just been turned on. This could be tested buy perhaps making two measurements and then looking only at the second one. This may turn out not to be a significant issue. Some investigation on how this affects the FFT output will need to be done to test this.

15th August 2021

It was determined that the weak reflected signal did not majorly affect the fft output especially considering that this data is scaled close to zero in the FFT windowing. A Gaussian filter was then coded up in the xm132 firmware to provide a bit of noise reduction and smoothing to the distance-velocity data. This Gaussian filter was implemented by using separating the 2d gaussian kernel into the outer-product of 2 1d gaussians kernels (also Gaussian). One of these gaussian kernels was applied across the rows and the other was apply across the columns. This data is now largely gives good information about the velocity information recorded by the sensor. A screenshot of the output of the sensor is shown on the left. It is seen that the xm132 and local computer produce very similar velocity-distance graphs. This is good verification that the data analysis implementation on the xm132 is working as intended. Note that the scale difference between the two distance-velocity graphs is due to different conventions used in the fft on the computer and xm132 and is not of much significance. Once important feature needed in the velocity sensor is the ability to differentiate between between two measurements and low signal measurements. One way to do this is via the amplitude as good measurements will have stronger reflected signals. However another way to do this is via the spread of the data. A velocity-distance distribution with all the data focused in a central point is typical in good measurements and those with data spread widely over the velocity-distance surface are more typical of random noise. I have attempted to calculate the standard deviation of the distribution to calculate this however this didn't discriminate between the two scenarios as very well. Currently some other measures of spread are being investigated for which works best. I believe one of the reasons the standard deviation does not differentiate very well is that even on strong measurements there is still a background signal roughly equal to the background signal on a noisy measurement. Additionally, the peak does not have a very large 'mass' about 10x the noise level. Hence its affect on weighting down the standard deviation is less than expected. I suspect any measure of spread which works well will need to take this into account.

19th August 2021

A solution was found to the measure of spread issue. The solution was to only calculate the measure standard deviation on the points which had a value above half of the maximum. An example image of this concept is shown below.

In the image the random noise represents the typical noise signal expected on the radar sensor. When this is run through the 50% level we expect the remaining points to be distributed broadly across the plot. This is because noise is uncorrelated. Hence when a standard deviation is measured. It returns a large value. However if some signal is present in the image when the 50% level is taken the points above this level should mostly be close the to signal center. Since the signal data is correlated in this way. When the standard deviation of this data is taken. Most of the remaining points are close to the peak so a smaller value is returned.

In testing this algorithm It was found that for a peak of amplitude ~2x the noise the worst case seen was the output standard deviation was twice as much as the standard deviation calculated on the data with the signal. Hence this test provides a good indicator of if the signal is noisy.

This will now be implemented in the XM132 firmware.

Having implemented this into the XM132 firmware. This firmware is now mostly complete. Further updates may come about as issues and ideas are found. However it is worth uploading this to the radar modules and being building radar sensors to test. I have made some of the variables in the data analysis modifiable at run-time by writing the the UART registers. This enables various different sub-routines of the data evaluation to be turned on and off, and some threshold values adjusted. This will help as it will allow the settings to be tweaked as found necessary without re-uploading the firmware.

26th August 2021

Today we have received the rev 0.1.1 versions of the radar velocity pcbs. These sensors already have a boot-loader preinstalled so are able to be uploaded from the Arduino IDE with the ATmega328PB bootloader out of the box.

The accelerator was verified to be in a working state.

The soft-start power switch as also verified. A 12 Ω resistor was placed between the switch output and ground and the switch was turned on. It took the switch 3ms to rise and in which time the ATmega328p did not reset itself. A plot of the switch rise is shown here:

It was also verified that all the UART and reset connection are working on the tri-state buffer which connects the ATmega328P to the radar velocity sensor.

A note for future revisions is to put the power and tri-state buffer enable on different pins to allow for easier programming.

The XM132 was then soldered onto the radar PCB. The best way found to do this is to add some solder to all the pads on the XM132, then add flux then place it onto the radar PCB. Applying a soldering iron to the exposed pads on the PCB solders the two components together

The next task was to burn the firmware onto the XM132. This proved more difficult than desired as we do not have a direct connection to the XM132 SWD (the reset pin is always pulled high or low by the arduino and hence we cannot reset it wit the J-link). It was tried to upload over uart through the ATmega328p however this also was had some difficulties and ultimately didn't work.

27th August 2021

Today we will continue working on how to upload the firmware to the XM132 while mounted to the radar velocity board. First we will test uploading through SWD, however to circumvent the reset constantly being pulled high by the arduino we will connect the reset pin to the an input on the arduino. We will then upload a script to the arduino to change the value of the reset pin connected to the XM132 based on this input.

Using this method the debugger is able to connect to the XM132. The firmware can then be uploaded to the XM132. For reference we are using this File:Radar velocity firmware.zip firmware. Once this is done the some issues needed to be fixed with the serial data such as the ATmega not receiving characters correctly. However once the baud rate was taken down to 57600. The device started functioning correctly again.

After much trying a good way to upload the firmware to the XM132 via UART was not found. The programmer could not connect to the XM132 for a reason I wasn't able to diagnose. We will thus need to upload the firmware via SWD. This will thus limit us to not being able to upload the firmware once the devices are potted in gel.

The firmware was tested in combination with the radar velocity board. After some bug fixing relating to different timings experienced between the computer and XM132 it was found that the the velocity and distance was able to be read out. For instance when the a hand was waved above the module. One issue which did crop up however was that long sweep lengths did not work. The velocity information would return zeros apart from the distance which would return 65 meters. The highest tested working sweep length was 1500 mm. I will need to investigate why this issue is occurring when we put the XM132 with the ATmega.

7th September 2021

The issue with long sweep lengths was fixed. This was caused by an error with the value set for the hardware accelerated averaged samples register. The power consumption was also verified. In full operation with the Radar on the system drew 55mA. When the radar power switch was set low and the ATmega328pb put to sleep the sleep mode current draw was about 300 μA. The remaining boards will now be assembled.

The firmware file used uploaded to the XM132 is available here File:Radar velocity STM firmware rev1.0.0.zip. This is uploaded via SWD with the following script uploaded to the ATmega File:Radar Velocity STM resetremap.zip

Hardware rev 1.0.0 updates

Based on the learning from rev 0.1.1 the following changes have been made to rev 1.0.0

- The tri-state buffer is not enabled with pin 7 on the ATmega, with the radar power switch remaining on pin 6.

- The CTS-RTS jumper for the XM132 is now default closed.

8th September 2021

One of the sensors made yesterday is now being tested in an inclined pipe. The sensor has been installed in the 3D printed case with the 3D printed radar lens. It has been placed a vertical distance 800 mm above the pipe and a hose pipe was used to flow water down the pipe. The pipe was inclined by 500 mm. The sensor was able to detect the water flow when placed at a range of angles of declination from the flow however a declination of 60 degrees from the pipe flow seemed to work best. The velocity recorded was quite variable +-100 mm/s difference in the measurement however some readings were at 100 mm/s. Interesting when the velocity resolution was doubled this reading became 50 mm/s. It is suspected that this is due to some sort of leakage in the lowest velocity bin. Perhaps it would be beneficial to introduce some sort of configurable band-pass velocity filter to mitigate this issue.

Below is the data table for the data collected with the rev 0.1.1 sensor. Some notable changes from defaults were that the register 0xD5 was set to 2000, and register 0xD7 was set to 3. The SWEEP_RATE was also reduced from 2E6 to 1E6 and the HW_ACC_AVE_SAMPLES increased to 50.

| Angle (deg) | Velocity (mm/s) | Distance (mm) | Amplitude (arb) | Spread (arb) | Height (mm) | Pipe Inclination (deg) | Angle Corrected Velocity (mm/s) |

|---|---|---|---|---|---|---|---|

| 70 | 312 | 1020 | 6400 | 20 | 200 | 8 | 624 |

| 72 | 317 | 1020 | 6300 | 20 | 250 | 9 | 634 |

| 74 | 341 | 1020 | 6400 | 8 | 300 | 11 | 681 |

| 76 | 405 | 1020 | 6800 | 4 | 350 | 13 | 810 |

| 78 | 420 | 1020 | 5200 | 37 | 400 | 15 | 840 |

| 80 | 440 | 1020 | 6500 | 31 | 450 | 17 | 880 |

| 82 | 434 | 1020 | 6700 | 41 | 500 | 18 | 868 |

| 85 | 469 | 1020 | 6500 | 29 | 550 | 20 | 938 |

The angle measure is the angle from the horizontal as measured by the onboard accelorometer. For the velocity, distance, amplitude, and spread measurements. 3 readings were recorded from the sensor. The velocity is given as the average velocity of these measurements. The distance measurement changed insignificantly between measurements and so was recorded directly. For the amplitude and spread the maximum returned value of the three measurements was recorded. The height column gives the height that the far end of the pipe was elevated.

From the data of the pipe inclination and the sensor angle we may conclude that the sensor was pointed at about 63 degrees declined from the water flow. We can use this to correct the Doppler velocity. (NB the pipe was remeasured and its length was actually 1440mm, not 1500mm as assumed in this analysis)

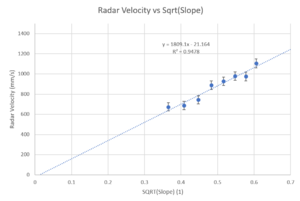

Below is a graph of the slope of the square root of the slope of the pipe against the velocity measured. Assuming gravity is the only force acting on the water. This graph should be linear with intercept zero.

The linear trend has an R2 value of 0.95 and the linear trend line is within the error bars of the data. (The error bars were calculated as half the width of one bin). Additionally the y-intercept is quite small. All these point towards that the sensor is working effectively to measure the velocity of the water in the pipe. However it is noted that some improvements might be attainable by further tweaking various parts data acquisition and processing setup.

23rd September 2021

To enclose the sensor some more test cases were printed. Different sizes for the front thread were tested to see which was the most waterproof. I have also updated the radar board again to the rev 1.1.0 which added a larger soldering header for the TTL cable.

29th September 2021

A further change has been made in the rev 1.1.1 design the FPF1038UCX power switch has been changed to the SIP32508. This was done for ease of soldering and durability reasons. The two power switches should perform similarly.

More testing has been done to try and find a good attachment method for the front lens on the radar sensor. This partly tweaking the 3d print design to create a better thread fit and also to tests sealants between the lens male and female thread. So far the following have been tested:

- Automotive grease

- PTFE tape

- none

all three of which had issues with leaking after a short period of time ~ 1 hour.

7th October 2021

It was found that some potting compound placed between the thread and the body worked well in preventing leaks over a timescale of days. Some final tweaks were made to the radar velocity case including adjusting screw hole diameters and tolerances. A instruction set on how to construct the sensor will be posted soon...

21st October 2021

A sensor was installed in the field at Old Joes creek together with a hach velocity sensor in a field test. The radar sensor has been connected to a BoSL datalogger which is uploading as OJ_RADAR_TEST approximately every minute. Specifically we are working with the rev 0.1.1 sensor. Data will be collected weekly from the hach sensor weekly, and will be posted here.

26th October 2021

It would be interesting to test how applying a Kalman filter to the data affects the velocity reading.

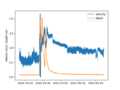

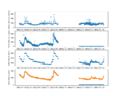

On the side here we have the plots of the week 1 data. Specifically we have from top to bottom radar velocity, hach velocity, radar depth, hach depth. The initial observations tell us that the velocity sensor is working as it is as the events between the two sensors seem to be correlated, however there exists significant noise present. It is suspected that some of the velocity readings for the of the hach sensor are anomalous as there is no change in water depth when this occurs and the events are not very continuous. The radar depth performance seems also at a first observation to perform well. One noteworthy point is that the chaotic depth measurements of the radar sensor on the 23rd of October are likely due to the sensor being submerged in the water at this point. The radar velocity measurements seem to be quite noisy so I think there is some work to do here on how best to pick out the velocity from the frequency domain plots.

NOTE: On 15 November 2021 at about 12:00 to 16:00 AEST another logger was logging to OJ_RADAR_TEST thus this data needs to be filtered out. It will probably be easiest by battery level.

28th October 2021

Looking at the data from collected this week it would be helpful to collect the full phase space portrait. To do this we will implement a way to slowly pass the buffer (of size about 4k and so too large to be stored in an ATmega328) to the SIM7000 where it may be uploaded via FTP or other means. That is the chain will look like XM132 -> radar sensor -> bosl -> sim7000. This is quite a long serial chain and so we need to perform a few handshakes a long the way to ensure that the signal is not having any information getting lost. To do this we will need up update the firmware of the XM132, radar sensor and bosl.

First we will get the XM132 -> radar sensor step working. After some code rearrangement this was able to be accomplished. The radar sensor -> bosl step was also completed. Now just remains the bosl -> sim7000 step.

6th November 2021

We now need to figure out how to get the FTP system working on the sim7000. The first step to this is to figure out how to write files to the sim7000 internal file system.

This can be done as follows

AT+CFSINIT AT+CFSWFILE=2,"filename",append,size,timeout file data

AT+CFSINIT initializes the file system

AT+CFSWFILE opens the file "filename" to be written to. The append option changes whether the file is appended to (1) or overwritten (0). The size of the data sent to the file should be sent in size, and all the data to be written should be sent within a time of timeout ms. Once this command is sent the word DOWNLOAD is returned by the sim7000, and the file contents should now be sent to the SIM7000 over serial.

The AT+CFSRFILE can be used to read the file.

Now to move on uploading this file via FTP. There does not seem to be an easy way to upload data directly from the SIM7000's flash memory via FTP, so it will have to be copied out in stages and gradually uploaded.

To enable an FTP transfer first

AT+SAPBR needs to be run to activate the bearer. Then: AT+FTPPORT AT+FTPMODE AT+FTPSERV AT+FTPUN AT+FTPPW

Can be run to set up the TFP connection. To set the file path of the upload

AT+FTPPUTNAME AT+FTPPUTPATH

Can be run, once this is set up

AT+FTPPUT

Can be run and then the upload data can be streamed to the sim7000 and the file should upload to the FTP server.

It has been found that instead of writing the file to a flash buffer using the AT+FTPEXTPUT=1 mode allows the file to be uploaded to be streamed into ram with AT+FTPEXTPUT=2. A simple call of AT+FTPPUT=1 will then upload the file. Using AT+FTPPUTOPT="STOU" will upload the file in the root directory of the ftp server with a name "pureftpd.xxxx". The xxxx is the unix timestamp in hexadecimal.

15th November 2021

The CAD files for the radar case are provided in the zip file: File:Radar-case.zip

22nd November 2021

Acconeer released their v2.9.0 version of the SDK, this includes improvements such as better handling of strong reflections and experimental extended range for space of 12.4 meters. It will be interesting to see if this means that we no longer need to stitch two space readings together, as this will significantly reduce measurement time and power. Unfortunately the sparse buffer is still limited by the 4kB size, which we have already maxed out, so we will have to continue using our current solution.

23rd November 2021

The versions of the radar firmware and bosl logging code which were used to just log the radar data and log the raw radar data were unified into a single code base. To change the mode of what the sensor logs can now be done by setting the VERBOSE flag in the bosl logging code. I have also added a mode to take the average of 6 readings.

24th November 2021

The Kalman filter has been implemented in python, currently the model being used is inertial, that is that the filter assumes that the velocity will change according to the current rate of change. As more data comes in the Kalman filter updates this this estimate of the velocity and the rate of change of velocity. The measurement of the rate of change of velocity is given by the change in velocity between the previous two measurements.

29th November 2021