Difference between revisions of "Turbidity Sensor"

| (125 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

| + | == Publication== | ||

| + | |||

| + | '''Please see the following link for the publication of the low-cost turbidity sensor | ||

| + | |||

| + | Website link: https://www.mdpi.com/1424-8220/24/12/3926 | ||

| + | |||

| + | PDF version:https://www.mdpi.com/1424-8220/24/12/3926/pdf''' | ||

| + | |||

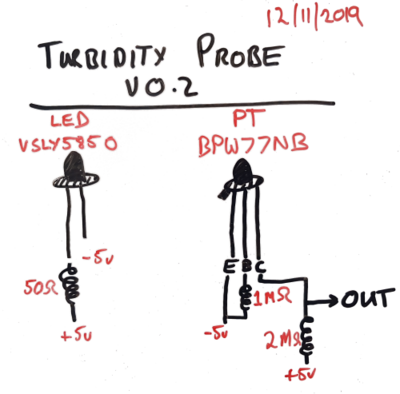

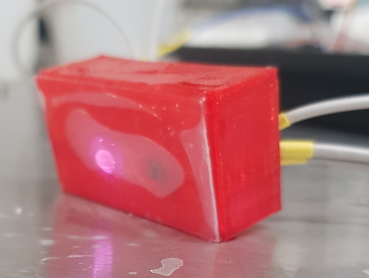

==12th November 2019== | ==12th November 2019== | ||

So we finally made some nice progress with the Turbidity Sensor design. | So we finally made some nice progress with the Turbidity Sensor design. | ||

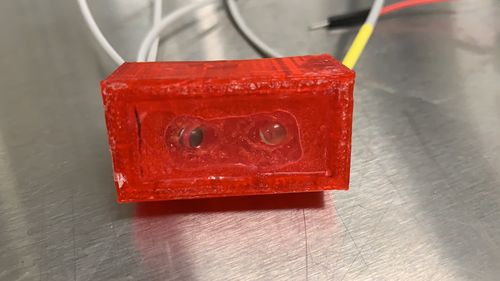

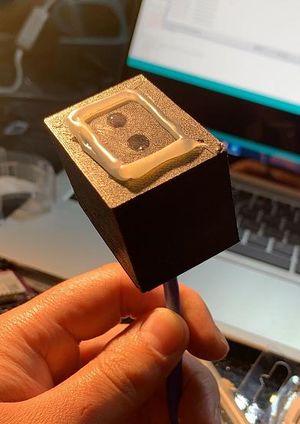

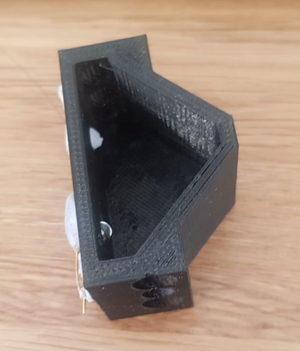

| − | + | The first step was to print our case using our 3D printer. Here it is: | |

[[File:TurbBoxV0.1.png|300px]] | [[File:TurbBoxV0.1.png|300px]] | ||

| Line 28: | Line 36: | ||

== 13th November 2019== | == 13th November 2019== | ||

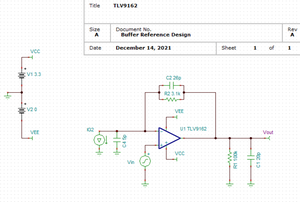

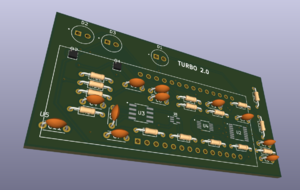

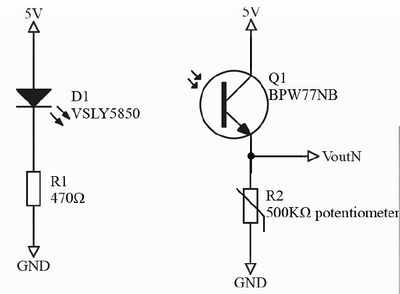

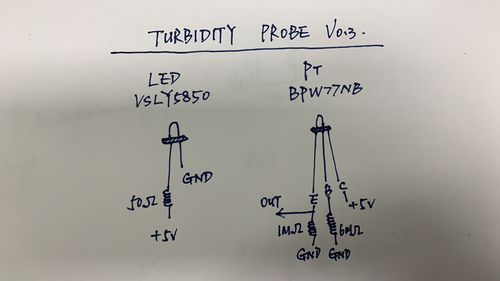

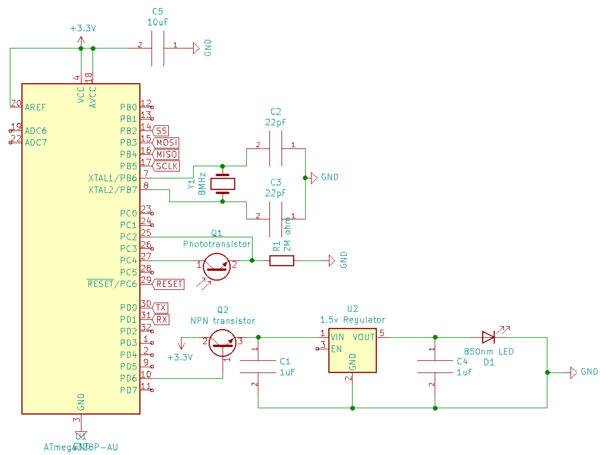

| − | So, today we began making our circuitry for the new turbidity sensor. It is looking good, but when we tried to print the board on our new PCB printer, the ink was all dried up! Come on Voltera, please send us the new ink so we can start printing our boards again! Here is an image of the circuit we made today in an easy to use program called EasyEDA. | + | So, today we began making our circuitry for the new turbidity sensor. It is looking good, but when we tried to print the board on our new PCB printer, the ink was all dried up! Come on Voltera, please send us the new ink so we can start printing our boards again! Here is an image of the circuit we made today in an easy to use a program called EasyEDA. |

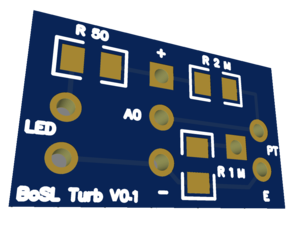

[[File:BoSL Turb V.01.png|300px]] | [[File:BoSL Turb V.01.png|300px]] | ||

| Line 34: | Line 42: | ||

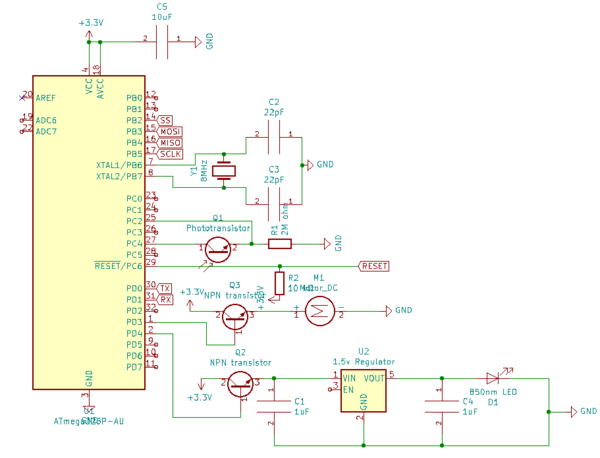

== 17th November 2019 == | == 17th November 2019 == | ||

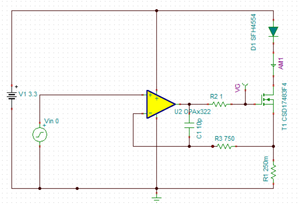

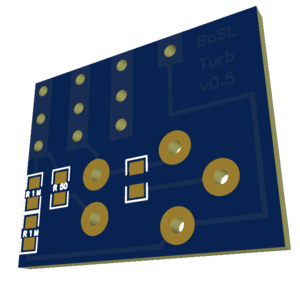

| − | We have begun designing our wiping device, but to do so we needed to revamp our circuit to allow for some motors to drive the wiping action. We began printing many different versions of the above board on our Voltera printer (thanks Voltera for finally giving us our consumables), but there were a hole bunch of issues...including that the holes and pads were not optimised for our Voltera. So, we spent the day designing a new circuit that now looks like... | + | We have begun designing our wiping device, but to do so we needed to revamp our circuit to allow for some motors to drive the wiping action. We began printing many different versions of the above-board on our Voltera printer (thanks Voltera for finally giving us our consumables), but there were a hole bunch of issues...including that the holes and pads were not optimised for our Voltera. So, we spent the day designing a new circuit that now looks like... |

[[File:BoSL Turb Probe v0.5.png|300px]] | [[File:BoSL Turb Probe v0.5.png|300px]] | ||

| Line 160: | Line 168: | ||

As we think we have found the critical factor, we just use the 6M ohm resistor on the base and then use the circuit to test the previous sensor(the red one with a piece of epoxy on the surface), we still put the red sensor in the black box, just as the same configuration as before, although the result is better than before, some results are still unreasonable, for example, in DI water, the analogue reading is 177 which is not 0. That means we still got some problem with our design, now we are thinking about how to change our sensor case and design. Also, the floating vibration problem still exists, we are planning to use our PCB printer to get a better board to get rid of this problem. | As we think we have found the critical factor, we just use the 6M ohm resistor on the base and then use the circuit to test the previous sensor(the red one with a piece of epoxy on the surface), we still put the red sensor in the black box, just as the same configuration as before, although the result is better than before, some results are still unreasonable, for example, in DI water, the analogue reading is 177 which is not 0. That means we still got some problem with our design, now we are thinking about how to change our sensor case and design. Also, the floating vibration problem still exists, we are planning to use our PCB printer to get a better board to get rid of this problem. | ||

<gallery> | <gallery> | ||

| − | Repeating paper results 6M ohm.jpg| | + | Repeating paper results 6M ohm.jpg|Repeating the paper experiment with 6M ohm resistor on the base |

| − | Repeating paper results 10M ohm.jpg|Repeating paper experiment with 10M ohm resistor on base | + | Repeating paper results 10M ohm.jpg|Repeating the paper experiment with 10M ohm resistor on the base |

Old sensor with 6m ohm on base.jpg|Use old sensor with 6M ohm resistor on base for testing | Old sensor with 6m ohm on base.jpg|Use old sensor with 6M ohm resistor on base for testing | ||

</gallery> | </gallery> | ||

| Line 179: | Line 187: | ||

== 2nd December 2019== | == 2nd December 2019== | ||

| − | Now we have two new sensors, one is a triangular case with half tube and another one is a triangular case with a whole tube, now we are going to use these two sensors for testing | + | Now we have two new sensors, one is a triangular case with half tube and another one is a triangular case with a whole tube, now we are going to use these two sensors for testing. |

Firstly, we still use the same circuit for testing, and when we found the analogue reading is small, we changed the resistor which connected to the base. From the past experience, we found the analogue reading is getting larger as the resistor connected to the base increases, so we used 20M ohm instead of 6M ohm on the base. | Firstly, we still use the same circuit for testing, and when we found the analogue reading is small, we changed the resistor which connected to the base. From the past experience, we found the analogue reading is getting larger as the resistor connected to the base increases, so we used 20M ohm instead of 6M ohm on the base. | ||

| Line 197: | Line 205: | ||

The sensor with a whole tube shows a similar result, as the 6M resistor is better than the 20M ohm resistor. | The sensor with a whole tube shows a similar result, as the 6M resistor is better than the 20M ohm resistor. | ||

| − | Another thing is that the sensor does work with 3.3v input voltage, however, we need to do change our design to optimize the circuit performance. | + | Another thing is that we have test the 3.3v input, and we found the sensor does work with 3.3v input voltage, however, we need to do change our design to optimize the circuit performance. |

| Line 205: | Line 213: | ||

== 3rd December 2019== | == 3rd December 2019== | ||

| − | Today we tested the performance of LED and the phototransistor with the different distance between | + | Now we need to think more and retest the previous experiment which using the flat sensor box. |

| + | |||

| + | Today we tested the performance of LED and the phototransistor with the different distance between the transparent epoxy and the parts. We use tape to make the LED and the phototransistor in a fix location, and then change the position of the transparent epoxy board. | ||

| + | |||

| + | [[File:Distance test setting.jpg|400px|Distance test setting]] | ||

| + | |||

| + | From the photo above, each unit is 5mm, when we made the LED and phototransistor face to face, the analogue reading is around 760 which is the largest number. Then we start to fix them in a specific location, then change the epoxy's location. Firstly, we make the transparent epoxy board touch the LED and the PT, the analogue is 0, and then we slowly make the epoxy far away from the two parts, in a certain distance the reading number became larger, and kept increasing until the intersection point, at that point, the reading number is 760 which is the largest number. After that, as the distance kept increasing, the number became decreasing and then became 0. Those results mean that: | ||

1. If the epoxy is as close as touching LED and the PT, the sensor does work; | 1. If the epoxy is as close as touching LED and the PT, the sensor does work; | ||

2. If the solution is within a certain distance away from the surface of LED and the PT, the turbidity of the solution can be detected by the sensor | 2. If the solution is within a certain distance away from the surface of LED and the PT, the turbidity of the solution can be detected by the sensor | ||

| + | 3. In a certain distance, the phototransistor cannot detect the reflected light from the LED, which means the sensor actually does not need a specific boundary condition, because the light cannot reach such far away distance. | ||

| − | + | From the results, we know that for the flat sensor box, we need to make the epoxy touch the LED and the PT, and this configuration makes the analogue reading is 0 in the air which means the setting of our previous design should be all right. Another thing is that we do not need a boundary condition in our design because the sensor can only detect the reflected light at a certain distance. | |

| + | |||

| + | Now the transparent epoxy board we use is much clear than the epoxy we used before, the next step we need to use this board for further testing. | ||

== 4th December 2019== | == 4th December 2019== | ||

| − | Today we are planning to test the sensor with a flat surface, and the epoxy | + | Today we are planning to test the sensor with a flat surface, and the epoxy needs to be glued on the surface of the sensor box. |

| − | At first, we | + | At first, we used 100% infill white box for testing. The distance between the two holes is 20mm(centre to centre). |

| − | Therefore, to solve the problems, we determine to use our 3D printer to print the 100% infill black sensor box, and to get rid of the light transmitting from the | + | [[File:White sensor box front.jpg|300px]] [[File:White sensor box back.jpg|300px]] |

| + | |||

| + | At the beginning of the test, we just put the LED and the PT in the two holes to test if the analogue reading is 0 in the air. However, we found that the analogue reading is not 0 when the two little bulbs are in the holes, we took them out and found even they are perpendicular to each other, the reading is not 0. When we used the black box to hide the LED, the analogue reading is still not 0. We found that two problems cause this result, one is the light source of LED is not from the edge of the bulb but the inner part, so the light can penetrate the glass bulb and be detected by the PT. Another problem is that the white box is not light-proof, so the light from the LED can be transmitted from the white box and it can be detected by the phototransistor. That can also explain why the analogue reading is not 0 in the air for the previous test(by using the red sensor box). | ||

| + | |||

| + | Then we used the 100% infill black box to test if the light will transmit through, and we found that the light cannot be transmitted through the black box. | ||

| + | |||

| + | Therefore, to solve the problems, we determine to use our 3D printer to print the 100% infill black sensor box, and to get rid of the light transmitting from the internal part of the box, the sensor box is designed to have two tube at the back the two holes, the two tubes will cover the body of the two bulbs so that light can no longer transmit through the sensor box. | ||

| + | |||

| + | [[File:New sensor box with plastic tube.jpg|300px]] [[File:New sensor box with plastic tube back.jpg|300px]] | ||

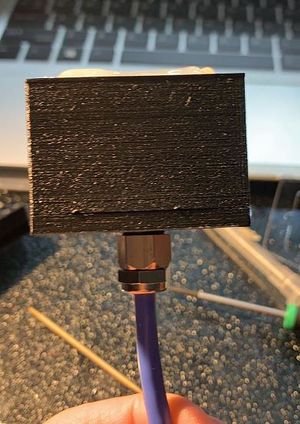

After we set up the sensor box, we glue the epoxy cover on the sensor box surface, and then start our test. The tested sensor is shown in the following photo: | After we set up the sensor box, we glue the epoxy cover on the sensor box surface, and then start our test. The tested sensor is shown in the following photo: | ||

[[File:New tested sensor box 3.3v.jpg|400px]] | [[File:New tested sensor box 3.3v.jpg|400px]] | ||

| − | |||

| − | |||

In our test, when the sensor is exposed in air, the analogue reading is 0, and in DI water, it is also 0. It is a good result as it matches our hypothesis. However, when we put it in the solution with 200NTU, the analogue reading is about 10, and when we use 1000NTU solution for testing, the reading number is about 76, so the problem is that the reading number is too small for calibration. | In our test, when the sensor is exposed in air, the analogue reading is 0, and in DI water, it is also 0. It is a good result as it matches our hypothesis. However, when we put it in the solution with 200NTU, the analogue reading is about 10, and when we use 1000NTU solution for testing, the reading number is about 76, so the problem is that the reading number is too small for calibration. | ||

| Line 235: | Line 258: | ||

== 5th December 2019== | == 5th December 2019== | ||

| − | The sensor box we used yesterday is a black box with 20mm distance between two holes(centre to centre). Now we use a new sensor box with 14.3mm distance between two holes. We use 14.3mm as the distance | + | The first thing we need to do is make the tube at the back of the hole shorter, so the LED and the PT are closer to the surface and can touch the epoxy. |

| + | |||

| + | The sensor box we used yesterday is a black box with 20mm distance between two holes(centre to centre). Now we use a new sensor box with 14.3mm distance between two holes. We use 14.3mm distance because in the past experiment the tube diameter we used is 19mm, so the distance between the LED and the PT is about 14.3mm. So we test this distance to see the performance. The new case can be seen as the following photo: | ||

| + | |||

| + | [[File:New sensor box with led and pt.jpg|400px]] | ||

| + | |||

| + | And we also connect LED and the PT to the Arduino and found the analogue reading is 0 in air, and when we put the transparent epoxy on the surface, the reading number is also 0. That shows the sensor works well. Next step, we are going to print more sensor boxes with different distance between the holes, 12mm, 10mm and 8.5mm, and then test if the distance between LED and the PT will affect the performance, and then we will choose the best one and test in solution. | ||

| + | |||

| + | To be continued…… | ||

| + | |||

| + | |||

| + | == 6th December 2019== | ||

| + | |||

| + | Now we have a sensor box family! Sensor boxes with different distance between holes(8.5mm, 10mm, 12mm, 14.3mm). And we will use these boxes for testing. | ||

| + | |||

| + | [[File:Sensor box family.jpg|400px]] | ||

| + | |||

| + | ==== Distance testing ==== | ||

| + | |||

| + | We try to put the transparent epoxy board in front of the different boxes with different distance, and then see the analogue reading in different distance. The results showed that if the two holes are closed, the distance between the board and the sensor box to reach the maximum reading number is smaller. For example, for the 14.3mm distance box, when the board is 3mm away from the box, the reading number is 380, and the reading number changed to 650 at 4mm distance. However, for 8.5mm distance box, the reading number is 650 when the board is 1mm away from the box. | ||

| + | |||

| + | So, after the test, we found 14.3mm between the holes is too far away and 8.5mm is too close, so we choose 12mm box and 10mm box for testing. | ||

| + | |||

| + | ==== Solution testing ==== | ||

| + | |||

| + | We used 10mm distance box and 12mm distance box to get the analogue reading in the different solution. For the 10mm box, the readings are still 0 for the solution below 80NTU, and for the 1070NTU turbidity solution, the analogue reading is only 128. For the 12mm box, the number is even smaller, for 1070NTU turbidity is 48. That result cannot be used for analysis. We have also changed the base resistor from 6M ohm to 20M ohm, however, when the resistor is larger than 7M ohm, the reading number in air and DI water is no longer 0, that is not what we want. | ||

| + | |||

| + | We compared with the current design and the previous test design(with round tube in the box), the difference between these two designs is the transparent board, one is a flat board and another is a round tube, that means the LED and the PT have a certain angle between the board, but with the tube, they are perpendicular to the tube surface. So we want to have another test which makes the LED and the PT perpendicular to the epoxy board and see if it will get better. | ||

| + | |||

| + | ==== New sensor box testing ==== | ||

| + | |||

| + | We use our 3D printer to print a new sensor box which is shown below, this sensor box can also make the LED and the PT perpendicular to each other, and the epoxy board could also be glued on the surface of the box which makes the board perpendicular to the bulbs. And the distance between the two bulbs is 14.3mm which is as same as the previous testing box(with a round tube in the centre). Our hypothesis is that if this sensor works, that means the epoxy board should be set as perpendicular to the LED and the PT, so we can try to cut two small round epoxy board and set them into the two holes which are perpendicular to the two bulbs. | ||

| + | |||

| + | [[File:New testing box for perpendicular board.jpg|300px]] | ||

| + | |||

| + | To be continued…… | ||

| + | |||

| + | |||

| + | == 10th December 2019== | ||

| + | |||

| + | Today we used the L shape sensor box for testing. When we started our test, we got a serious floating vibration problem. When the sensor is exposed in air, the analogue reading is not 0, the range is between 8 to 21, and the numbers keep changing. | ||

| + | |||

| + | To solve this problem, we try to change the resistor on the base and on the emitter. For the base, when we changed the resistor from 6M ohm to 4M ohm and then 1M ohm, the analogue reading number became smaller but still not 0, and the floating vibration problem still exists. We have also changed the PCB board to the breadboard, but the situation did not change. The resistor on the emitter has also changed, however the analogue reading did not change too much. | ||

| + | |||

| + | At last, we used a new LED and a new phototransistor which are soldered by new wire, this wire we used is thicker and more rigid than that we used before. After we changed that, the analogue reading in the air is constantly 0. However, when we face the PT to the lamp, in a certain angle, the reading increases. | ||

| + | |||

| + | Now we found that the floating vibration problem may be caused by the wire, and the lamp may emit light which can be detected by the phototransistor, and that problem may affect the results of our experiments. | ||

| + | |||

| + | In the following test, we still need to use a black box for solution container to avoid noise from the lamp or other light sources. | ||

| + | |||

| + | To be continued…… | ||

| + | |||

| + | |||

| + | == 18th December 2019== | ||

| + | |||

| + | New update for our turbidity sensor. | ||

| + | |||

| + | Now we need to continue testing the last sensor with L shape sensor box. This time, to avoid the noise from the breadboard, we would not connect the resistors in the breadboard, instead, we will solder the resistor on the pins. Apart from that, to get rid of the noise from the lamp or the laptop screen, the solution will be contained in a black box which is printed by our 3D printer, and the cap of the black box is also printed. That cap will cover the top of the box, only one small hole will sit on the cap to allow the cables to come out, with this configuration, the noise from the other light source will almost be eliminated. | ||

| + | |||

| + | Just wait for the 3D printer completing the printing task, and then we can use the case and the container for testing. | ||

| + | |||

| + | To be continued…… | ||

| + | |||

| + | |||

| + | |||

| + | == 19th December 2019== | ||

| + | |||

| + | All the facilities for testing are completed this morning, as usual, we still use the liquid epoxy to glue the plastic board on the sensor case, and then pouring the liquid epoxy at the back of the LED and the phototransistor so that the sensor is fully water-proof. When testing the sensor, the solution container will be covered by the cap. The testing facilities can be seen as the following pictures: | ||

| + | |||

| + | |||

| + | |||

| + | [[File:L shape sensor testing1.jpg|200px]] [[File:L shape sensor testing2.jpg|200px]] [[File:L shape sensor testing.jpg|200px]] | ||

| + | |||

| + | |||

| + | This time, the thick wire and the black container with a cap are used to avoid the noise. As a result, the analogue reading is much stable than before. When we put the sensor in the black box and covered with the cap, the analogue reading is constantly 0, and the reading number is also 0 in DI water, the floating vibration problem is almost disappeared. | ||

| + | |||

| + | By testing different solution, the results are shown in the table: | ||

| + | [[File:L shape sensor testing result.jpg|500px|right]] | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! Media(NTU) !! Analogue reading | ||

| + | |- | ||

| + | | Air(in black box) || 0 | ||

| + | |- | ||

| + | | 0.18 || 0 | ||

| + | |- | ||

| + | | 62 || 0 | ||

| + | |- | ||

| + | | 82 || 0 | ||

| + | |- | ||

| + | | 165 || 26 | ||

| + | |- | ||

| + | | 432 || 198 | ||

| + | |- | ||

| + | | 600 || 220 | ||

| + | |- | ||

| + | | 1036 || 352 | ||

| + | |} | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | The problem is that the analogue reading number is too small for the solution below 100NTU(almost 0), so it is not suitable for stormwater monitoring. | ||

| + | |||

| + | The reason may be the light source is not strong enough, we need to change some settings to let the light source stronger. For example, the successful sensor insert the tube in the middle of the case and the tube can congregate the light as a concave lens, can we use concave lens on the top of the LED to get the light source together? | ||

| + | |||

| + | We will try to do this kind of thing. | ||

| + | |||

| + | To be continued…… | ||

| + | |||

| + | |||

| + | ==20th January 2020== | ||

| + | |||

| + | We got the new update of our turbidity sensor development. | ||

| + | |||

| + | Now we have done several tests: distance test, LED resistor test, and the PT base resistor test. | ||

| + | |||

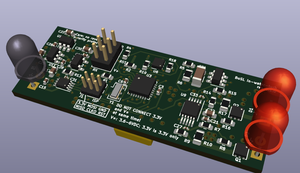

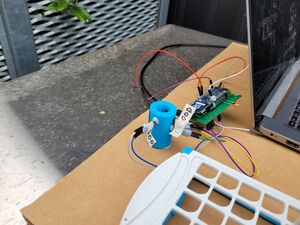

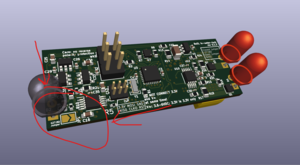

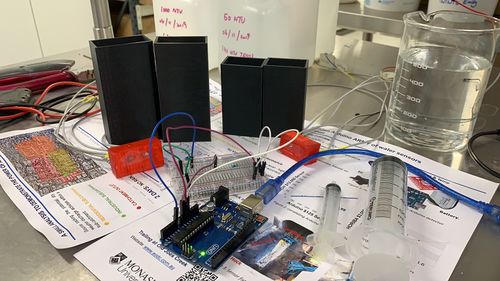

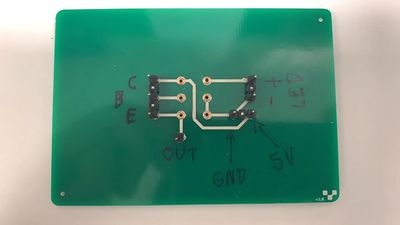

| + | Now we are using our new turbidity sensor board, this board is small and easy to connect all the pins when testing, and the analogue reading output is also more stable than the breadboard, the following picture shows our new board. | ||

| + | |||

| + | [[File:Sensor board pcb.jpg|300px]] | ||

| + | |||

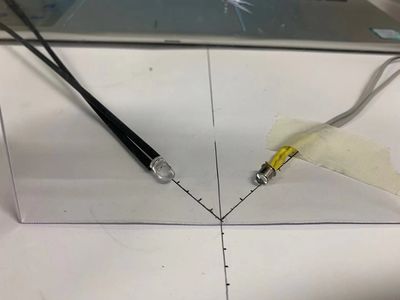

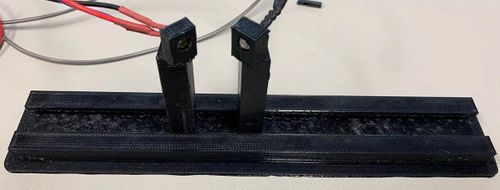

| + | To make sure the LED and the PT sit at the fix position, we used our 3D printer to print a rail and the LED and PT holder, the holder can move on the rail and stand at a fixed position, as the following figure shows. | ||

| + | |||

| + | [[File:Rail and holders.jpg|500px]] | ||

| + | |||

| + | For all the test we did this time, we just put the LED and the PT in the holders and change some factors(distance, resistors, type of LED) to see what factor affects the results most. By this configuration, the closest distance between the LED and the PT is 6mm, that means at 6mm distance, the edges of the holders touch each other. And for the circuit, the input voltage is 5V. This time we did not glue the epoxy on the holder. | ||

| + | |||

| + | |||

| + | ==== Distance test==== | ||

| + | |||

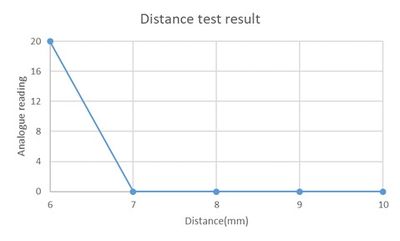

| + | Experiment Description: To test which distance will affect the analogue reading of the LED and the PT. We use the 6 degrees angle LED(brought from digikey), and use 51ohm resistor connecting to the LED, for the phototransistor, connecting 1M ohm resistor on the emitter, and connecting 5M ohm resistor on the base. By changing the distance between the LED and the PT(centre to centre) in the air, and use the cardboard box to cover them(making dark environment and avoiding noise), then record the analogue readings to see what the closest distance can be used between them. The closest distance means when we put them in the air, the analogue reading should be 0. | ||

| + | The results for this circuit configuration is in the table below: | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | | Distance(mm) || 6 || 7 || 8 || 9 || 10 | ||

| + | |- | ||

| + | | Analogue reading || 20 || 0 || 0 || 0 || 0 | ||

| + | |} | ||

| + | |||

| + | [[File:Distance test results.jpg|400px]] | ||

| + | |||

| + | That means for this configuration, the closest distance should be 7mm(centre to centre). | ||

| + | |||

| + | ==== LED resistor test==== | ||

| + | |||

| + | Experiment Description: As the last test shows when put the PT and the LED within 6mm distance, it has analogue reading. We just use this distance, and change the resistor on the LED, and then see how the analogue reading changes. We still use the 6 degrees angle LED, and the 1M ohm resistor on the emitter, 5M ohm resistor on the base. | ||

| + | |||

| + | The results are shown in the table below: | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | | LED resistor(ohm) || 10 || 20 || 50 || 100 || 200 | ||

| + | |- | ||

| + | | Analogue reading || 200 || 100 || 20 || 0 || 0 | ||

| + | |} | ||

| + | |||

| + | [[File:LED resistor test results.png|400px]] | ||

| + | |||

| + | This result shows that in this configuration, if the resistance of the LED circuit decreases, the analogue readings increase, which also means that the LED is brighter. '''However, when we use 10 ohm resistor for the LED circuit, the resistor is super hot that even hand cannot touch it. | ||

| + | ''' | ||

| + | |||

| + | ==== PT base resistor test ==== | ||

| + | |||

| + | Experiment description: From the LED resistor test, the analogue reading in 10 ohm resistor is 200 which is a large number, so we just use the resistor as 10 ohm which will obviously show the changes of analogue reading when we change the base resistor. In this test, we change the base resistor from 2M ohm to 20M ohm, and the analogue reading also changes, the reuslts are shown in the following table. | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | | Base resistor(Mohm) || 2 || 5 || 7 || 10 || 20 | ||

| + | |- | ||

| + | | Analogue reading || 30 || 200 || 300 || 380 || 860 | ||

| + | |} | ||

| + | |||

| + | [[File:Base resistor test result.jpg|400px]] | ||

| + | |||

| + | This result shows that as the base resistor increases, at the same configuration, the analogue readings increase, and we need to choose a right resistor to make the analogue reading is 0 in air within a certain distance between LED and the PT. | ||

| + | |||

| + | To be continued...... | ||

| + | |||

| + | |||

| + | == 22 January 2020 == | ||

| + | |||

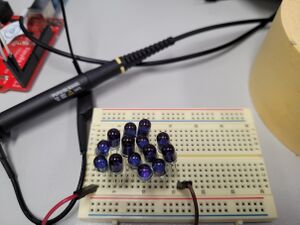

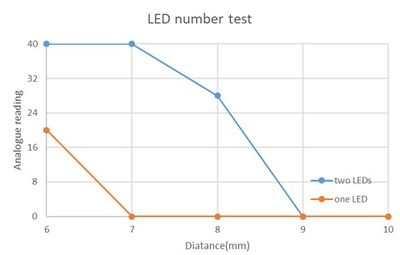

| + | ==== LED number changing test ==== | ||

| + | |||

| + | Experiment description: As we try to make the LED brighter, so we are thinking to add the number of LED, now we use two LEDs in the circuit, and the two LEDs are vertically set in a new LED holder. In the circuit, the resistor for the LEDs is 50 ohm, by changing the distance, record the analogue reading and compare with the results of the distance test. | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | | Distance(mm) || 6 || 7 || 8 || 9 || 10 | ||

| + | |- | ||

| + | | Analogue reading || 40 || 40 || 28 || 0 || 0 | ||

| + | |} | ||

| + | |||

| + | [[File:LED number test.jpg|400px]] | ||

| + | |||

| + | |||

| + | From the result, it can be seen that, with two LEDs, the analogue is doubled at 6mm distance and it also has readings at 7mm distance and 8mm distance, which means more LED will make the light source brighter. Next test, we will change the configuration for further test:1. make the LEDs horizontally beside each other 2. change the LED resistor to 10 ohm and see the performance. | ||

| + | |||

| + | |||

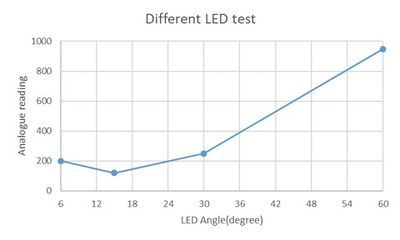

| + | ==== Different LED test==== | ||

| + | |||

| + | Experiment description: Now we have four types of LEDs: LED with 6 degrees(from Digikey), LED with 15 degrees(from China), LED with 30 degrees(from China), LED with 60 degrees(from China). Now we need to test the impact by using different angles. This time we use 10 ohm resistor LED, 5M ohm resistor on base, 1M ohm resistor on emitter. The distance between the LED and the PT is 6mm. The result is shown below. | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | | LED Angle(degree) || 6 || 15 || 30 || 60 | ||

| + | |- | ||

| + | | Analogue reading || 200 || 120 || 250 || 950 | ||

| + | |} | ||

| + | |||

| + | [[File:Different LED test result.jpg|400px]] | ||

| + | |||

| + | From the result, we can see that, the LED from Digikey is different from the Chinese LEDs, for the Chinese LEDs, as the angle increases, the analogue reading also increases. To make the analogue reading large enough in the low turbidity solution, I think we need to choose a large angle LED for testing. | ||

| + | |||

| + | Next tests, we will try to test the different angles between the LED and the PT, NOT ONLY FOR 90 DEGREES BETWEEN THEM. And we also need to do tests in water to see how the sensors perform in water. | ||

| + | |||

| + | To be continued…… | ||

| + | |||

| + | |||

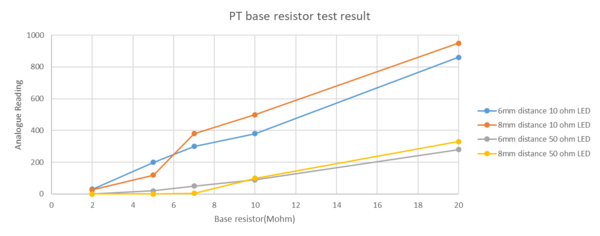

| + | == 24th January 2020 == | ||

| + | |||

| + | We have repeated the PT base resistor test, this time we not only change the resistors connecting to the base, but also change the distance and the resistor on the LED. This time we make the distance at 6mm and 8mm, and the resistor on the LED are 10ohm and 50oh. And other configuration of the circuit did not change. | ||

| + | |||

| + | The results can be seen as the table below: | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | | Base Resistor(ohm) || 2M || 5M || 7M || 10M || 20M | ||

| + | |- | ||

| + | | 6mm distance 10ohm LED || 30 || 200 || 300 || 380 || 860 | ||

| + | |- | ||

| + | | 6mm distance 50ohm LED || 0 || 20 || 50 || 90 || 280 | ||

| + | |- | ||

| + | | 8mm distance 10ohm LED || 26 || 120 || 380 || 500 || 950 | ||

| + | |- | ||

| + | | 8mm distance 50ohm LED || 0 || 0 || 5 || 100 || 330 | ||

| + | |} | ||

| + | |||

| + | [[File:Multiple test results 1st.png|600px]] | ||

| + | |||

| + | This result also shows that with the same configuration, if the distance is larger, the analogue reading is smaller, and in the same distance and resistor on base, if the resistor on the LED is larger, the analogue reading is smaller, and also the larger the resistor on the base, the larger the analogue reading it is. | ||

| + | |||

| + | I think the next step, we need to use two LEDs for testing as they may have larger analogue readings, maybe we should use 8mm as the distance, and try to do the experiment in the solution(maybe 200NTU solution), see how it will perform. | ||

| + | |||

| + | Will start the new experiment very soon. | ||

| + | |||

| + | |||

| + | |||

| + | == 4th February 2020 == | ||

| + | |||

| + | Today we are going to do the reflection test. We want to see what the analogue reading will be if we put some materials in front of the LED and the PT with different distance. Now we choose two kinds of materials, both of them have rough surface, one is the washing sponge and another is the face mask. Now the setting of the circuit is: the distance between the LED and the PT is 8mm, the resistor on the LED is 51ohm, and the resistor on the base is 5M ohm, the resistor connecting the emitter is 1M ohm. For the LED, we use 6 degree angle LED from the digi-key, the following figures shows the sponge and the face mask. | ||

| + | |||

| + | [[File:Face mask.jpg|200px]] [[File:Washing sponge.jpg|200px]] | ||

| + | |||

| + | And the test results are shown below: | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | | Distance from the LED and the PT(mm) || 0 || 1 || 2 || 3 || 4 || 8 || 10 || 12 | ||

| + | |- | ||

| + | | Green sponge analogue reading || 1003 || 1003 || 1003 || 980 || 450 || 75 || 10 || 0 | ||

| + | |- | ||

| + | | Face mask analogue reading || 1003 || 1003 || 1003 || 990 || 639 || 34 || 0 || 0 | ||

| + | |} | ||

| + | |||

| + | In the test, we we take the analogue, we make sure that the LED and the PT are in a dark environment, and without the reflect material, the analogue reading is constantly 0. | ||

| + | |||

| + | |||

| + | == 10 February 2020 == | ||

| + | |||

| + | Now we think that the main problems for our turbidity sensor are two things: | ||

| + | |||

| + | 1. When we use the epoxy board on the surface of the sensor box, the light would transmit from the board and it can be detected by the phototransistor, to solve this problem, we need to make the light polarized. And we can redesign the sensor box which adds a barrier in the middle of the two holes, if so, the light cannot transmit by the epoxy board. The new sensor box looks like the following picture: | ||

| + | |||

| + | [[File:Hide in middle sensor box.jpg|300px]] | ||

| + | |||

| + | |||

| + | 2. After double-checking the mechanism of the existing turbidity sensors, it seems that all the light beam is a direct light beam without angle. Previously, the light from the LED is divergent light, and it may cause the phototransistor receives light from different directions, and maybe the floating vibration is also caused by this problem. To solve this problem, many designs use a lens in front of the LED to make the light concentrated, some designs also add a lens in front of the phototransistor as well. We try to design our new sensor box by adding a small hole in front of the LED, so the light from the LED may transmit from the little hole, maybe this light will be a direct light beam. | ||

| + | |||

| + | [[File:Small LED hole design front.png|300px]] [[File:Small LED hole design back.png|300px]] | ||

| + | |||

| + | |||

| + | Now we are printing the new box by our 3D printer, after it completed, we may use the epoxy to glue a new board on the surface of the box, and then test them in the water, see what will happen. | ||

| + | |||

| + | To be continued...... | ||

| + | |||

| + | |||

| + | == 13 February 2020 == | ||

| + | |||

| + | Until now, our turbidity sensor's analogue reading still got the fluctuation problem, sometimes the analogue reading fluctuates within a very big range, it is very difficult for us to get an accurate result. When doing an experiment, we found that the Arduino board and the LED is getting hot after a long-time work. So we thought the fluctuation problem may be caused by the unstable light source, as the Arduino and LED are getting hot, they are not in a normal working condition, if so, the LED may not emit the stable light. Therefore, we are planning to use another power supplier for the LED, to get rid of long-time working, we also use a relay in the LED circuit, the relay can make the LED work intermittently. | ||

| + | |||

| + | After we set up the circuit, we use the round hollow section turbidity sensor for testing, the sensor still got the fluctuation problem, so it seems that the problem is not caused by the unstable light from the LED. | ||

| + | |||

| + | We need to use other ways to solve this problem, to be continued…… | ||

| + | |||

| + | |||

| + | |||

| + | == 14 February 2020 == | ||

| + | |||

| + | Now we still use the external power supply for the LED and looking for ways to solve the fluctuation problem. We tried to add a "pull up" function in our code to make the PT work better. After we upload our new program to the Arduino, the Analogue reading results are much more stable than those in the previous test. All the results fluctuate in a very narrow range which means we almost solve the fluctuation problem. | ||

| + | |||

| + | Now we use the round hollow section turbidity for testing, and the circuit we use is Dave's circuit, which has 2M ohm resistor on the collector and 1M ohm resistor on the base. In this test, we found that the analogue reading is too large for all the solution, for example, the reading number for DI water is about 990, and the reading number is about 900 in the 500NTU solution, that is difficult for us to analyse the results. We need to change some configurations to make the results perfect. | ||

| + | |||

| + | To be continued…… | ||

| + | |||

| + | |||

| + | == 16 February 2020 == | ||

| + | |||

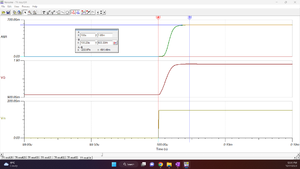

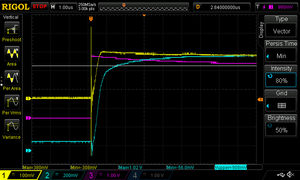

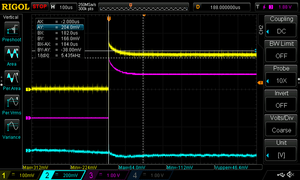

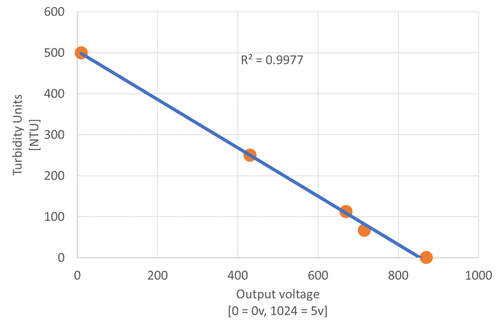

| + | We found that the analogue reading is very sensitive to the current of the LED, if we have a tiny change of the LED current, the analogue reading changes a lot. Therefore, we connect a multimeter to the circuit to measure the accurate current of the LED. Then we change the resistors on the base and collector. After we tested many times, we found that one configuration for the round hollow section turbidity sensor works very well, the results of different turbidity solution got a linear trend. | ||

| + | |||

| + | In this configuration, the resistor on the base is 4M ohm, and the resistor on the collector is 2M ohm, the current of the LED 0.1A. The result is shown in the following diagram: | ||

| + | |||

| + | [[File:Turbidity sensor results 0216 dave.jpg|450px]] | ||

| + | |||

| + | Now we can use this configuration for more test, but first thing we need to do is repeat the test and make sure it is reproducible. | ||

| + | |||

| + | |||

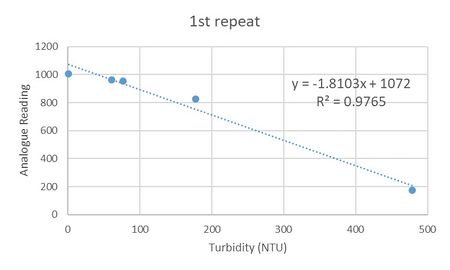

| + | ==17 February 2020 == | ||

| + | |||

| + | Today we repeat yesterday's experiment. However somethings changed: | ||

| + | |||

| + | 1. Today we make all the turbidity solution in the container, the container is a black box printed by our 3D printer and the black box can make sure the sensor will be in an absolutely dark environment; | ||

| + | 2. We use our turbidity meter to test each solution to make their turbidity accurate; | ||

| + | 3. In the first two tests, the current is 0.1A, however, the results are different, and the current always changed by itself, so in the third test, the current was changed to 0.13A and the results are better. | ||

| + | |||

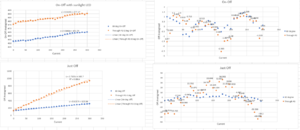

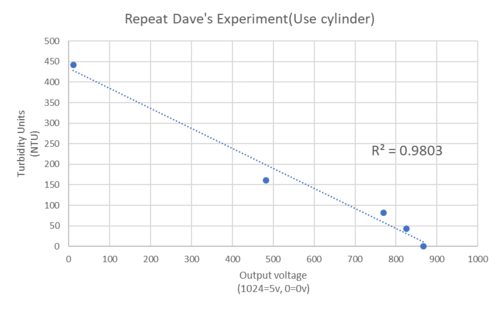

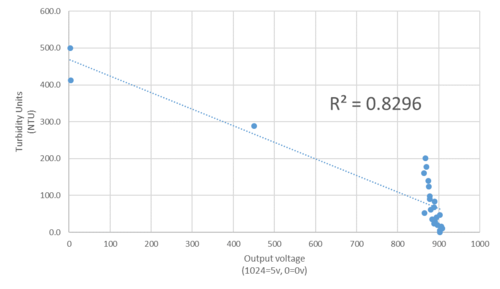

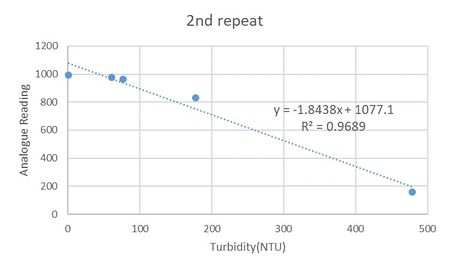

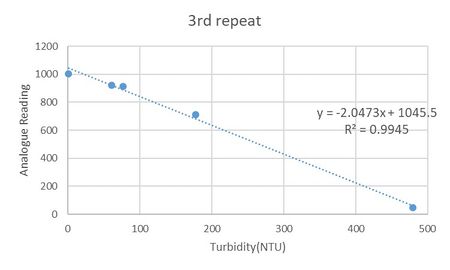

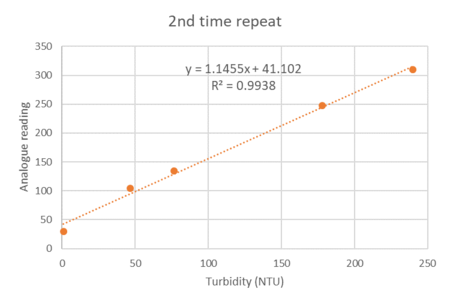

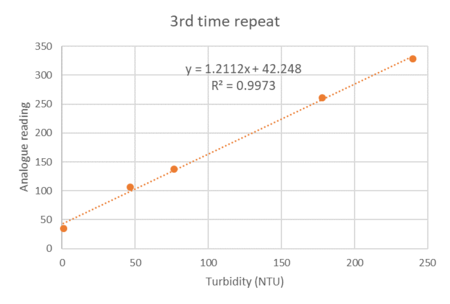

| + | The following diagram shows the test results, the first two diagrams are results in 0.1A current, and the third one is under 0.13A current. | ||

| + | |||

| + | [[File:1st repeat 0217.jpg|450px]] [[File:2nd repeat 0217.jpg|450px]] [[File:3rd repeat 0217.jpg|450px]] | ||

| + | |||

| + | The following things need to be done are: | ||

| + | |||

| + | 1. Keep repeating the hollow section experiment, and make sure this experiment is reproducible; | ||

| + | 2. Try to use a flat case for testing. | ||

| + | |||

| + | To be continued…… | ||

| + | |||

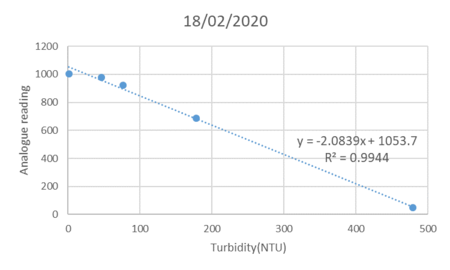

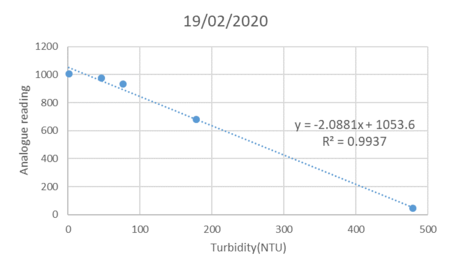

| + | == 19 February 2020 == | ||

| + | |||

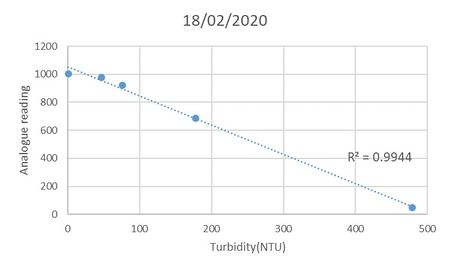

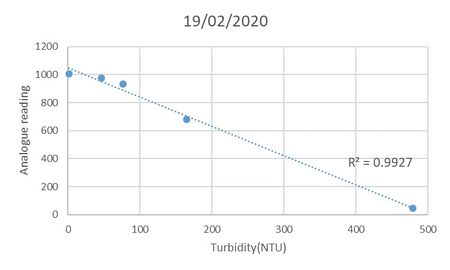

| + | The experiment is tested every day to see if it can get the same result, the results for yesterday and today are shown below: | ||

| + | |||

| + | [[File:Repeat 0218.jpg|450px]] [[File:Repeat 0219.jpg|450px]] | ||

| + | |||

| + | |||

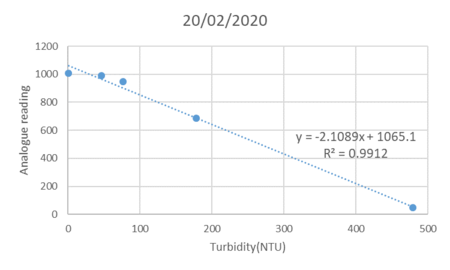

| + | == 20 February 2020 == | ||

| + | |||

| + | Today we have done two things: | ||

| + | |||

| + | ==== Repeat the previous experiment ==== | ||

| + | |||

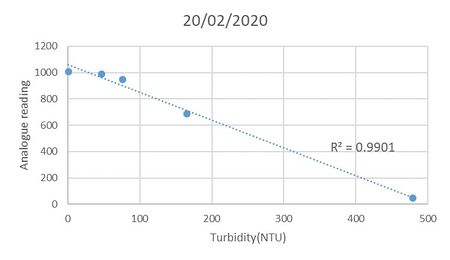

| + | The previous test had been repeated for one more time today, the configuration was as same as the previous test, use 2M ohm resistor on the collector, 4M ohm resistor on the base and use 0.13A current for the LED, the results are shown below: | ||

| + | |||

| + | [[File:Repeat 0220.jpg|450px]] | ||

| + | |||

| + | This result is similar to the past two days' results, which means the experiment can be replicated. | ||

| + | |||

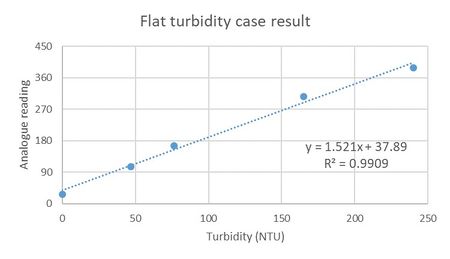

| + | ==== Try to use the flat turbidity case for testing ==== | ||

| + | |||

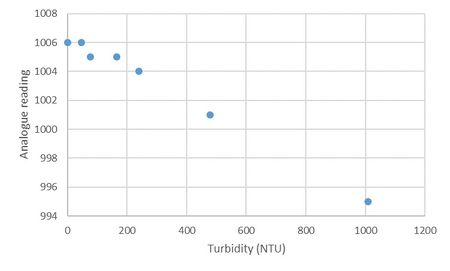

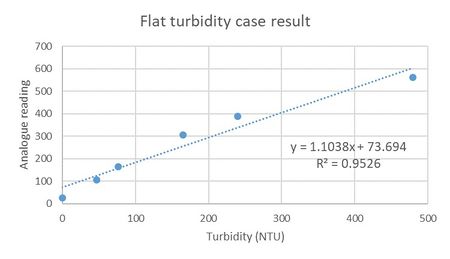

| + | As we replicate the experiment successfully, we try to use the falt turbidity case for testing. For the flat case, the distance between the two holes on the case is 19mm, and the epoxy board is about 1.5mm thickness, we use the glue gun to glue the transparent epoxy board on the case, and test the case in different turbidity solution. The circuit is as same as the circular case, the only difference is to the LED and the PT in a falt case. We test the falt one in different turbidity solution, the result is shown below. | ||

| + | |||

| + | [[File:Flat case results bad.jpg|450px]] | ||

| + | |||

| + | Although the points look like a linear relationship. the differential rang is too small(from 995 to 1006), so the result is not good enough. | ||

| + | |||

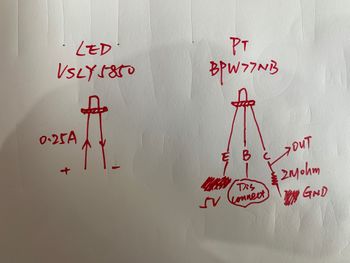

| + | Now we want to try to change our settings of the circuit, we use a 500K potentiometer connecting on the collector, and then disconnected the base, then try to see the analogue reading. We found that, the analogue reading increases as the resistance increases. However the analogue reading for 500K ohm is still more than 70, so we changed the current of the LED to 0.25A, the reading numbers changed to 135 for the 500k resistance. So we changed the resistor to a larger one, 2M ohm resistor made the analogue reading 561 at 480NTU solution. The results can be seen in the following diagram: | ||

| + | |||

| + | [[File:Base disconnected.jpg|350px]] [[File:6 points results 0220.jpg|450px]] | ||

| + | |||

| + | However, if we only use the first 5 points for plotting, there was a better linear trend: | ||

| + | |||

| + | [[File:5 points results 0220.jpg|450px]] | ||

| + | |||

| + | Now it looks better, but still have two problems: | ||

| + | |||

| + | 1. 0.25A is too large for the LED, we need to adjust it; | ||

| + | 2. The analogue reading in the air and in DI water is not 0, we need to try to change some settings to make it perfect. | ||

| + | |||

| + | We need to repeat the test later to see if this configuration can get the same result, and we also need to adjust the configurations to optimize the performance. | ||

| + | |||

| + | To be continued…… | ||

| + | |||

| + | == 24 February 2020 == | ||

| + | |||

| + | For our turbidity sensor, today we have done two things: | ||

| + | |||

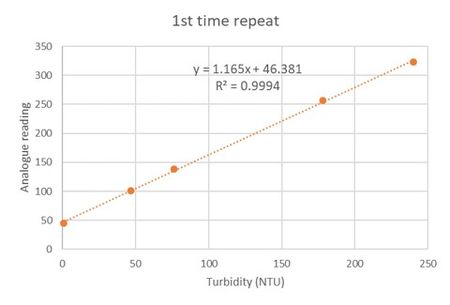

| + | ==== Repeat the previous flat case experiment ==== | ||

| + | |||

| + | We used the same configuration of the flat case experiment last week, 0.25A current, 2M ohm resistor on the collector, and the 1.5mm coverage. Today we record 10 analogue reading numbers for each solution and used the average number to plot the diagram. | ||

| + | |||

| + | This time, the trend is similar to the results last week, but the numbers are different. Today the reading numbers are smaller than those we recorded last week, but still form a linear relationship. We need to keep repeating the experiment every day to see if it can still get the same results. Today's results are shown below: | ||

| + | |||

| + | [[File:1st repeat flat 0224.jpg|450px]] | ||

| + | |||

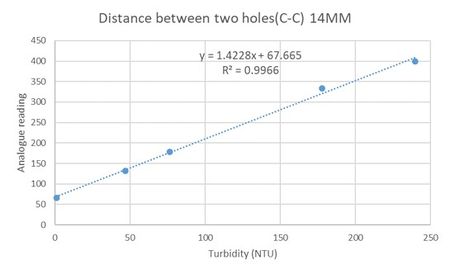

| + | ==== Change the distance between the two holes ==== | ||

| + | |||

| + | As the 0.25A current is too large for the LED and this also consumes too much power, we want to change it to low current, but it will affect the analogue reading numbers, so we tested the new case with a closer distance between two holes. The distance between two holes is 14mm now. Firstly, we still use the 0.25A current and see how the reading numbers change, with this configuration, the analogue reading number increased for each solution. The results can be seen in the following diagram: | ||

| + | |||

| + | [[File:Flat case 14 C-C.jpg|450px]] | ||

| + | |||

| + | With these results, we still used the 14mm case but changed the current to 0.1A, the reading number for DI water changed to 28, but the analogue reading in 240NTU solution changed to 93, that number is too small, so the next step we try to change the resistor on the collector, or make the distance between two holes closer. | ||

| + | |||

| + | Another thing is that the PT can get better performance at the solution below 300NTU, we are thinking to use a photodiode in our sensor as well. | ||

| + | |||

| + | To be continued…… | ||

| + | |||

| + | |||

| + | == 27 February 2020 == | ||

| + | |||

| + | Too busy these days, new update for our turbidity sensor. | ||

| + | |||

| + | Today we did several things: | ||

| + | |||

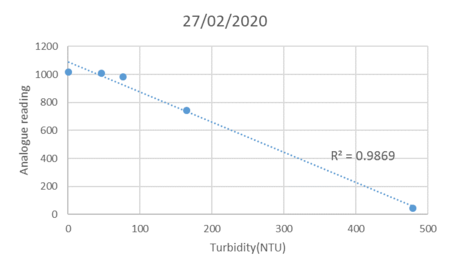

| + | ==== Repeat the circular case turbidity sensor experiment ==== | ||

| + | |||

| + | Today we repeated the circular sensor experiment, we did not change any configuration, all the settings are as same as before: 0.13A current for the LED, 4M ohm resistor on the base, 2M ohm resistor on the collector, we also take 10 analogue readings for each solution and calculate the average number of the analogue reading for plotting. | ||

| + | |||

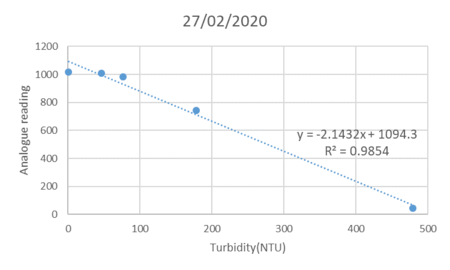

| + | Today's results are higher than the previous results, and the points did not fit a linear relationship perfectly, R square for the points is 0.987, the results and diagram are shown below. | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | | Turbidity(NTU) || 1(DI water)|| 46.8 || 76.5 || 178 || 479 | ||

| + | |- | ||

| + | | Analogue Reading || 1017 || 1007 || 984 || 743 || 47 | ||

| + | |} | ||

| + | |||

| + | [[File:4th repeat circular.png|450px]] | ||

| + | |||

| + | we have checked all the connections and the circuit, there is no difference with the previous configuration, the difference may be caused by the unstable power supply of the LED, as the current of the LED can be measured by the multimeter, the current changed slightly during the experiment, that may be the reason of the difference. | ||

| + | |||

| + | ==== Repeat the flat case turbidity sensor ==== | ||

| + | |||

| + | We use the flat case with 19mm distance between two holes, also we connect 2M ohm resistor on the collector, the current for the LED is 0.25A, the thickness of the coverage is 1.5mm, we used the glue gun to glue it on the surface of the case. Similarly, we recorded ten readings numbers and calculate the average. This time, the results are similar to the results in the previous experiment. The diagram below shows the results: | ||

| + | |||

| + | [[File:2nd flat repeat.png|450px]] | ||

| + | |||

| + | |||

| + | ==== test the different hole distance case ==== | ||

| + | |||

| + | As 0.25A is too large for the LED and it also consumes too much energy, we need to change the current lower, now we use 0.1A current for the LED, and then make the two holes closer. Today we used 0.1A current for our LED and tested four different cases, the distance between the two holes of the four cases are 19mm, 14mm,12mm and 10mm respectively. Each case we tested different solution, and then compare their performance, and also see which one is the best for our sensor. | ||

| + | |||

| + | The results are shown in the following diagram: | ||

| + | |||

| + | [[File:Different distance case test en.png|800px]] | ||

| + | |||

| + | From the diagram it can be seen that the results of all the cases followed a linear relationship, the closer the distance, the wider the range is. For example, for the 10mm distance case, the largest number is 744 for 1010NTU, and the smallest number is 68 for DI water, the 12mm distance performs similar to the 10mm distance case. The wider range works better for our monitoring. Next time, we can try to use 10mm case for further test. | ||

| + | |||

| + | |||

| + | ==== Validate the middle barrier test ==== | ||

| + | |||

| + | Last time we thought that it should be useful to add a barrier in the middle of the epoxy board, because the light may transmit by the epoxy board and affect the analogue reading. These days we were using two small pieces of epoxy board to cover the LED and the PT respectively, and use the glue gun to make a barrier in the middle. Today we did a test to validate the function of the middle barrier. | ||

| + | |||

| + | We use two 19mm distance flat case, one with a middle barrier, another one uses an entire epoxy board to cover the LED and the PT(without barrier), then tested them in different solution, compare the analogue readings. | ||

| + | |||

| + | The results are shown below: | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | | Turbidity(NTU) || 1010 || 479 || 240 || 178 || 76.5 || 46.8 || 1 | ||

| + | |- | ||

| + | | without middle barrier ||467 || 280 || 170 || 152 || 75 || 57 || 39 | ||

| + | |- | ||

| + | | with barrier || 396 ||262 || 162 || 132 || 72 || 53 || 29 | ||

| + | |} | ||

| + | |||

| + | From the results, the reading numbers for the case with barrier are smaller than that without middle barrier, although not too much difference but make sense. That may caused by the long distance between the two holes, 19mm distance is a little bit far for the LED and the PT, light could not transmit easily with this distance. However, this experiment shows that it is useful to add a barrier in the middle to prevent light transmitting through the transparent board. | ||

| + | |||

| + | Next step work: | ||

| + | |||

| + | 1. Use 10mm distance case for further tests, change the resistors to make the reading number better; | ||

| + | |||

| + | 2. Calibration for the sensor to see which range turbidity is best for the PT's performance; | ||

| + | |||

| + | 3. Prepare the experiment for the photodiode(depends on the results of calibration). | ||

| − | [[File: | + | To be continued…… |

| + | |||

| + | |||

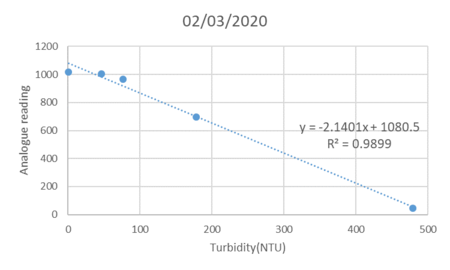

| + | == 2nd March 2020 == | ||

| + | |||

| + | ==== Repeat the circular case test ==== | ||

| + | |||

| + | Today we did the 5th repeat test of the circular turbidity sensor. This test roughly fit a linear relationship, but not as perfect as the previous experiment. The five times result can be seen in the following diagrams: | ||

| + | |||

| + | [[File:Circular 1st repeat.png|450px]] | ||

| + | [[File:Circular 2nd repeat.png|450px]] | ||

| + | [[File:Circular 3rd repeat.png|450px]] | ||

| + | [[File:Circular 4th repeat.png|450px]] | ||

| + | [[File:Circular 5th repeat.png|450px]] | ||

| + | |||

| + | From the diagrams above, we can see the reading numbers are stable, but still have uncertainty. | ||

| + | |||

| + | ==== Repeat the flat surface case with 19mm distance experiment ==== | ||

| + | |||

| + | We used the 19mm distance flat case for testing, today's test is the 3rd time test, the test is similar to the circular test, the results of the three test are shown below. | ||

| + | |||

| + | [[File:19 flat 1st repeat.png|450px]] | ||

| + | [[File:19 flat 2nd repeat.png|450px]] | ||

| + | [[File:19 flat 3rd repeat.png|450px]] | ||

| + | |||

| + | It also has problems, for this case, the linear relationship only fit the turbidity solution between 0 to 250NTU, if we plot the curve including 480NTU result, the points do not fit a good linear line. The diagrams are shown below. | ||

| + | |||

| + | [[File:19 flat 1st repeat non.png|450px]] | ||

| + | [[File:19 flat 2nd repeat non.png|450px]] | ||

| + | [[File:19 flat 3rd repeat non.png|450px]] | ||

| + | |||

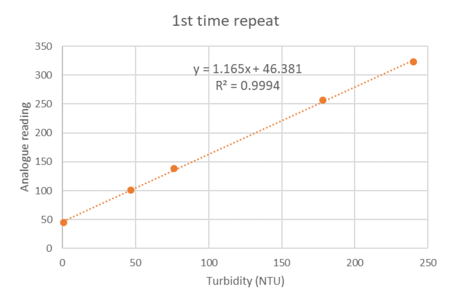

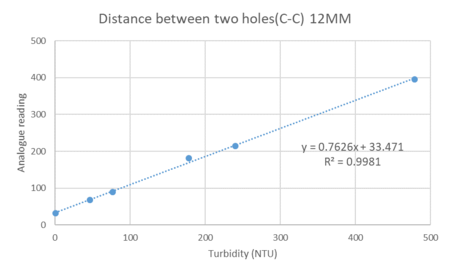

| + | ==== Test 12mm distance flat surface case ==== | ||

| + | |||

| + | As we tested last time, the 12mm distance flat case and the 10mm distance flat case have a wider range of results, as the 10mm distance is too close, we used 12mm distance case for testing. The test we did today recorded ten reading numbers for each solution, and use the average to plot the curve. | ||

| + | |||

| + | The readings from 0 to 479NTU solution fit a perfect linear relationship(R square is 0.9981), if we plot the 1010NTU result on the curve, the curve did not fit the linear relationship perfectly, R square is 0.9889, still not bad. | ||

| + | The following diagram shows the result: | ||

| + | |||

| + | [[File:12mm flat test 1st.png|450px]] | ||

| + | [[File:12mm flat test 1st non.png|450px]] | ||

| + | |||

| + | |||

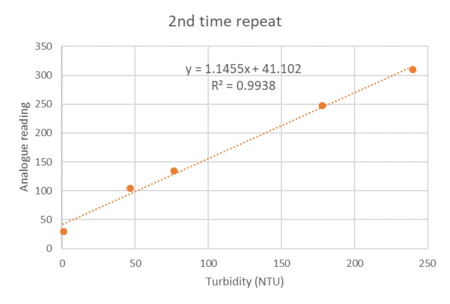

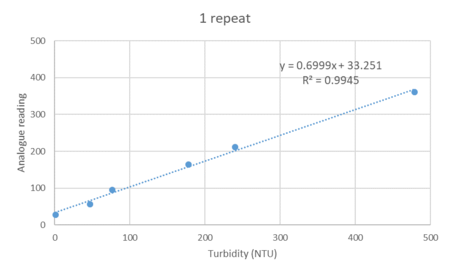

| + | == 3rd March 2020== | ||

| + | |||

| + | Today we repeated the 12mm distance flat surface test. | ||

| − | + | Previously, we use the glue gun to form the middle barrier of the case, now we found the light may transmit throuth the glue gun material, so we change the middle barrier. Now we used the epoxy to glue the two pieces of epoxy cover on the case, and glue a piece of blue tack in the middle and then test the sensor. The following diagram shows the result: | |

| − | [[File: | + | [[File:12 flat 1st repeat.png|450px]] |

| + | [[File:12 flat 1st repeat non.png|450px]] | ||

| − | + | Both of the reuslts form not bad linear relationship, but still have uncertainty, next step we need do two things: | |

| + | 1. repeat the test again and again to get as more results as possible, and then determine the uncertainty; | ||

| + | 2. use a regulator to make the input voltage constant and then do the test. | ||

To be continued…… | To be continued…… | ||

| + | |||

| + | == 4th March 2020 == | ||

| + | |||

| + | Today, we tested the middle barrier test again. Previously, we use the case which is 19mm distance between two holes, we thought it is too far away for the light to transmit, so we are not sure if the middle barrier can be used or not. Today we used the 12mm distance case for the test, one with middle barrier which is blue tack, and another one is a whole epoxy board on the surface, the two testing case can be seen in the following picture. | ||

| + | |||

| + | |||

| + | [[File:Middle barrier test 12mm.jpg|600px]] | ||

| + | |||

| + | In this test, we tested the middle barrier case for two times, and tested the case without middle barrier once, each test we recorded 10 analogue reading numbers and used the average value for plotting. All the results showed a not bad linear relationship, especially for 0-500NTU turbidity solution. The results and diagrams are shown below. | ||

| + | |||

| + | '''The experiment results can be seen in the table below:''' | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | | Item || 1010NTU || 479NTU || 240NTU || 165NTU || 76.5NTU || 46.8NTU || 1NTU(DI water) | ||

| + | |- | ||

| + | | case without middle barrier || 839.8 || 432.3 || 268.6 || 203.4 || 107.5 || 75.9 || 32.5 | ||

| + | |- | ||

| + | | case with middle barrier 1st time || 620.9 || 365.5 || 212.1 || 161.6 || 84.3 || 57 || 35.5 | ||

| + | |- | ||

| + | | case with middle barrier 2nd time || 619.8 || 368.2 || 213.3 || 167.6 || 86 || 57.6 || 32.3 | ||

| + | |} | ||

| + | |||

| + | |||

| + | We can also see the plotting diagram: | ||

| + | |||

| + | [[File:Middle barrier test 12 1-500NTU.png|650px]] [[File:Middle barrier test 12 1-1010NTU.png|650px]] | ||

| + | |||

| + | From the results, it can be seen that the analogue range for without middle barrier case is larger than the other one, and the results also form a linear relationship, so the case without middle barrier works better. | ||

| + | |||

| + | In the following experiment, we will try to use the case without the middle barrier for further testing. | ||

| + | |||

| + | |||

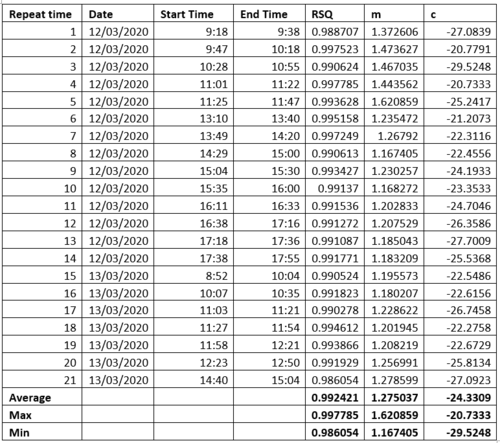

| + | == 12th March 2020 == | ||

| + | |||

| + | In the past week, we used the flat case with a whole epoxy board to repeat the test. We want to know the uncertainty of the sensor. So we want to repeat the test several times, if the data is enough, we can use them to determine the relationship of the analogue reading and the turbidity, and also the uncertainty of the sensor. | ||

| + | |||

| + | For the configuration of the test: | ||

| + | The distance between the two holes: 12mm | ||

| + | The thickness of the epoxy board: 1.5mm | ||

| + | Collector: 2M ohm resistor | ||

| + | LED: 1.56v voltage and 0.1A current | ||

| + | |||

| + | Until now, we have repeated 21 tests. The results can be seen in the following table: | ||

| + | |||

| + | [[File:Repeat test results 2.png|500px]] | ||

| + | |||

| + | From the table, we can see that the R square is not bad, but the slope and the intercept varies a lot. We thought it is still the problem of the external power supplier of the LED. When we tested the sensor, the current of the LED always changes, we have to manually change the voltage to make the LED current 0.1A, but it still not stable enough. Sometimes the unstable voltage will affect the performance of the LED. We need to use a regulator to make the voltage constant. | ||

| + | |||

| + | When the LED has 0.1A current, the voltage for the DC power is 1.55V. So next step we will buy a 1.55 voltage regulator to make the voltage constant and stable, and then repeat our test. | ||

| + | |||

| + | == 14th March 2020== | ||

| + | |||

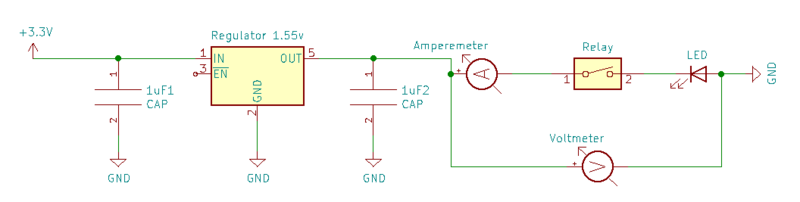

| + | We got the 1.55v voltage regulator. And when we use the regulator in our circuit, the output voltage of the regulator is constantly 1.54V. The circuit of the LED can be seen as follows: | ||

| + | |||

| + | [[File:Circuit regulator 1.png|800px]] | ||

| + | |||

| + | But when we test the circuit, the current of LED is only 0.07A, the voltage drop of the circuit is 1.4v not 1.54v. We think it may be the problem of the relay, so we did not connect the relay in the circuit, just connect the LED in the circuit, now the circuit is like the following diagram. | ||

| + | |||

| + | [[File:Circuit regulator no relay 2.png|700px]] | ||

| + | |||

| + | With this circuit, the voltage drop of the LED is also 1.4v, so the current of the LED is not 0.1A. | ||

| + | |||

| + | But the LED still works, as the voltage decrease, the analogue reading number became smaller, which means it still forms a kind of relationship, but the range of the analogue reading is narrow. For example, the analogue reading number of 1000NTU turbidity solution is around 660 but now it is only more than 420. | ||

| + | |||

| + | We are waiting for our new regulator to come, and before that, we will use this one for testing, and see what kind of relationship will it form. | ||

| + | |||

| + | |||

| + | == 16th March 2020 == | ||

| + | |||

| + | We start to test the sensor, today we did not use realy in the LED circuit, we keep the LED on, and the current of the LED is 0.07A. Each time after the test, we used the turbidity meter to test the turbidity of the solution in the solution to make the experiment more accurate. After 6 tests, the results can be seen as the table below: | ||

| + | |||

| + | [[File:Repeat test without relay results1.png|600px]] | ||

| + | |||

| + | These results are not bad, as the voltage regulator can output the constant voltage, the slop and the intersection of the line has less vibration. However, in the field, we still want to make the LED work intermittently, so next step, we will add the relay in our circuit and repeat the test. | ||

| + | |||

| + | |||

| + | == 17th March 2020 == | ||

| + | |||

| + | Today we used the relay in our LED circuit, and other things did not change. We have done 6 tests today, the results can be seen as follows: | ||

| + | |||

| + | [[File:Repeat test with relay results1.png|600px]] | ||

| + | |||

| + | Now the results are not bad, when the new regulator comes, we can use 0.1A to test the performance, if it still works well, we can use the regulator for our design. | ||

| + | |||

| + | The next step, we have several things to do: | ||

| + | 1. Use our BoSL board for further testing; | ||

| + | 2. Get motor work for wiper; | ||

| + | 3. Design the PCB for the sensor. | ||

| + | |||

| + | |||

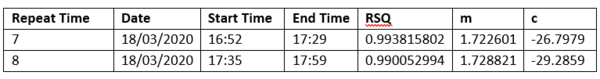

| + | == 18th March 2020== | ||

| + | |||

| + | After fieldwork today, we repeated two times of the experiment in the afternoon, the results can be seen as follows: | ||

| + | |||

| + | [[File:Repeat test results 0318.png|600px]] | ||

| + | |||

| + | == 19th March 2020== | ||

| + | |||

| + | Today, we change a little bit of the LED circuit, we put the relay just before the LED and then still repeat the test for 14 times, now we have already repeated the test for 20 times. The summary results can be seen in the following diagram: | ||

| + | |||

| + | [[File:Repeat test results 0319 summary.png|600px]] | ||

| + | |||

| + | It can be seen that the slop is slightly different from the test before we change the relay. I think the problem does not come from changing the circuit, but from the connection of the breadboard. Although the result is different, there is no large vibration which is good. The next step I think we need to do is design the circuit and PCB board, and wait for the new regulator comes and do more tests. | ||

| + | |||

| + | == 24th March 2020== | ||

| + | |||

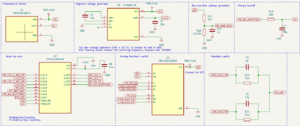

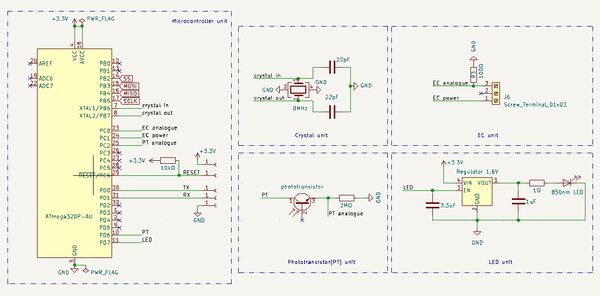

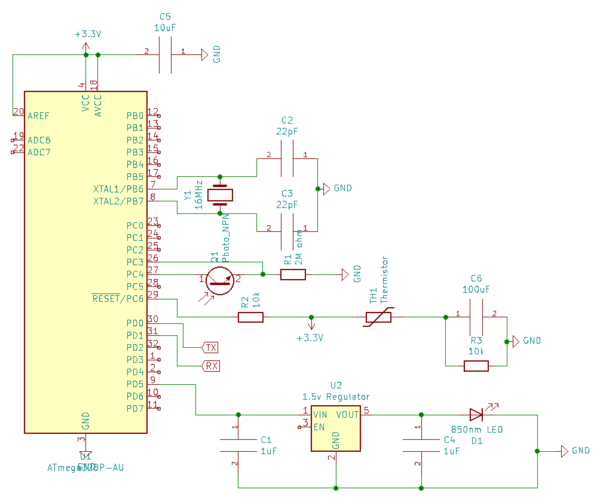

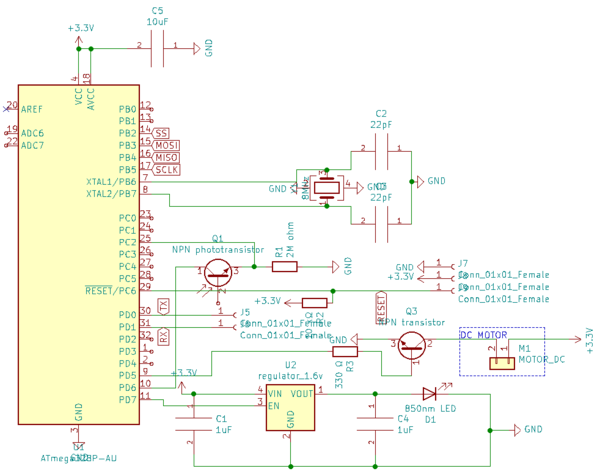

| + | Today we designed the circuit of the board, we use the ATmega328P-AU as our controller, the circuit diagram can be seen as the following diagram, it has already been sent to Stephen for double-check, once it is confirmed, we can process to test it. Next step we need to design the case of the sensor with the motor. | ||

| + | |||

| + | [[File:Circuit diagram.png|600px]] | ||

| + | |||

| + | ==26th March 2020 == | ||

| + | |||

| + | Today we did several things: | ||

| + | |||

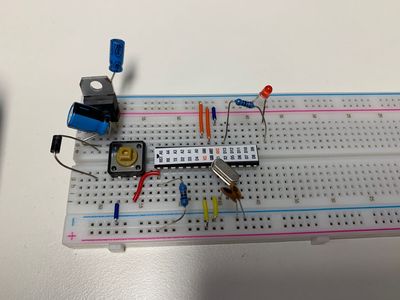

| + | ==== Test the breadboard Arduino==== | ||

| + | |||

| + | Now we have already set up a breadboard Arduino, base on this test, we are sure that the chip can be used on the PCB to control the turbidity sensor. This time, we did not upload the turbidity sensor code on the board, for testing purpose, we only use a simple blink code to make a LED blink. As it works successfully, we can use a similar thing later for testing. | ||

| + | |||

| + | [[File:Breadboard Arduino.jpg|400px]] | ||

| + | |||

| + | Next step, we will only use this chip to control the turbidity sensor and see if the results will be the same. | ||

| + | |||

| + | ==== Test the BosL board turbidity sensor ==== | ||

| + | |||

| + | We connect the turbidity sensor on our BoSL board, just like the circuit diagram above, we use two digital pins and "HIGH" and "LOW" code to control on and off of the LED and the phototransistor, but we got the problem, as the digital pin of Arduino can output maximum 20mA current, however the current we need for our LED is 100mA, so this connection is not able to support the turbidity. | ||

| + | |||

| + | To ensure we still control on and off of the turbidity sensor, we need to change our design, the power of the LED circuit will be provided by 3.3v directly, but we need to use an NPN transistor to work as a switch, and then use the digital pin to control the whole circuit. | ||

| + | |||

| + | ==== Change the design of the circuit ==== | ||

| + | |||

| + | Due to the issue we talked above, we have to change our circuit, not only the LED diagram, but also the crystal, now we change the 16Mhz crystal to 8Mhz crystal. We also add some pins on the board. | ||

| + | |||

| + | [[File:Circuit diagram new.png|600px]] | ||

| + | |||

| + | ==27th March 2020== | ||

| + | |||

| + | ==== Test on BoSL board==== | ||

| + | |||

| + | Today we assembled all the parts on the BoSL board, as the circuit we used above, we used the NPN transistor to control the LED circuit, the circuit is connect directly to the 3.3v pin. Therefore, in this circuit, the LED and the phototransistor are all supplied by 3.3v. | ||

| + | |||

| + | The NPN transistor worked successfully, we can use "HIGH" and "LOW" code to control on and off of all the circuit. So in the following design, we can add NPN transistors for the final design. | ||

| + | |||

| + | We also tested the analogue reading, when we set the sensor in dark environment in air, the analogue reading is about 25, and in DI water, the analogue reading is around 6, to make the sensor face the table, the analogue reading number is supposed as the largest number which is more than 920, that results are not bad. We need to test them in more calibrated turbidity solution later. | ||

| + | |||

| + | ==== Modify the circuit diagram ==== | ||

| + | |||

| + | The circuit diagram is finalised, we have changed some parts of the diagram, also we set some pins for the motor and set NPN transistor to control that, a pull-up resistor is added for the reset button. | ||

| + | |||

| + | [[File:Final circuit diagram v1.png|600px]] | ||

| + | |||

| + | == 4th April 2020== | ||

| + | |||

| + | After we designed the circuit diagram, we need to combine all the things on a PCB, so we need to design a PCB. | ||

| + | |||

| + | ==== Change the circuit diagram ==== | ||

| + | |||

| + | As we want to make the PCB as small as possible, so we need to make sure all the route goes wisely, and if so we changed the circuit diagram. However, we did not change any parts of the circuit, only change the pin connections to make the parts can easily connect to the ATmega microcontroller. The new circuit diagram can be seen as follows: | ||

| + | |||

| + | [[File:Final circuit diagram v1.1.png|600px]] | ||

| + | |||

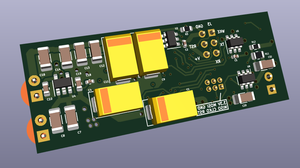

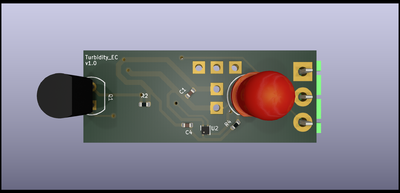

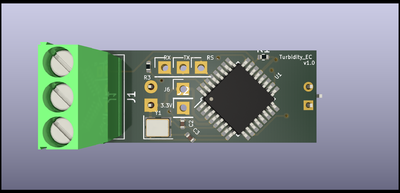

| + | ==== Design PCB ==== | ||

| + | |||

| + | As we changed the circuit diagram, we can design the PCB. The dimension of our PCB is about 24mm*12mm which is a double-sided board, the distance between the LED and the phototransistor is 12mm. As we only need emitter and collector pin of the phototransistor, we deleted the base footprint of the PT. The PCB designed diagram can be seen as follows. | ||

| + | |||

| + | [[File:Final PCB footprint front v1.1.png|500px]] [[File:Final PCB footprint back v1.1.png|600px]] | ||

| + | |||

| + | This design will send to our PCB supplier to print. | ||

| + | |||

| + | == 5th May 2020 == | ||

| + | |||

| + | After one month, finally, we got our turbidity PCB, the tiny PCB dimension is 24mm*12mm, the following picture shows the real turbidity PCB. | ||

| + | |||

| + | [[File:PCB real 1.jpg|200px]] [[File:PCB real 2.jpg|250px]] | ||

| + | [[File:PCB real 3.jpg|250px]] [[File:PCB real 4.jpg|250px]] | ||

| + | |||

| + | == 9th May 2020 == | ||

| + | |||

| + | In the past days, we tested the PCB, as we need to make the testing simple, we did not solder the LED and the PT on the board, instead we solar some pins on the board, and then connected the previous LED and PT to the PCB, and use the previous case to test the analogue reading. | ||

| + | |||

| + | When we put a barrier in front of the case surface, the analogue reading is 1023, which is the largest value. When we put the sensor in air(not in black box), the analogue reading is 55-70, that is a reasonable result which shows the PCB works well. The next step, we need to use place the PCB and the sensor in a proper case and test the analogue reading in solution. | ||

| + | |||

| + | Please wait for the new testing results. | ||

| + | |||

| + | To be continued...... | ||

| + | |||

| + | == 14th May 2020 == | ||

| + | |||

| + | Some new updates for the turbidity PCB testing. The whole process is a little bit complicated. | ||

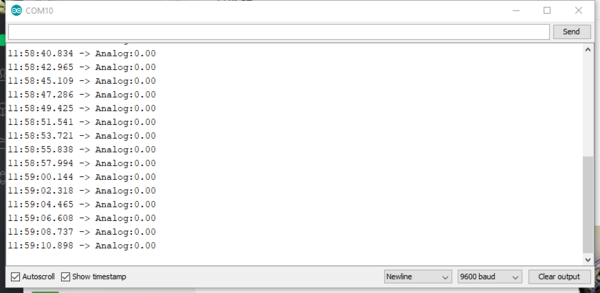

| + | |||

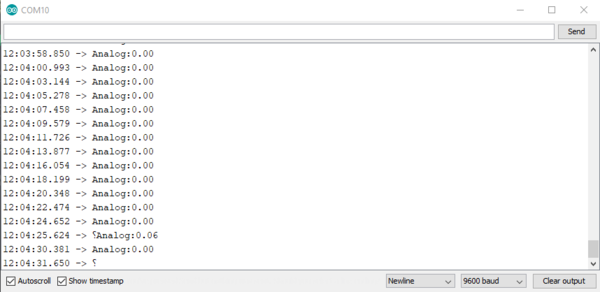

| + | Now we want to use the ethernet cable to connect the PCB, so I desolder the pins on the PCB and connect the Ethernet wires on the holes: TX, RX, restart, GND and 3.3V. It's a little bit hard to desolder the pins and solder the wires into the holes, and after doing that, we uploaded the program into the PCB, it is a very simple code to let the PCB scan 1s and turn off the LED and PT for 1s. So, on the serial monitor, we can see the analogue reading updates every 2 seconds. Even we did not plug the LED and the PT, there will be new analogue reading which is 0. it can be seen as the following diagram; | ||

| + | |||

| + | [[File:Analogue reading good.png|600px]] | ||

| + | |||

| + | Before I soldered the LED and the PT on the board, I used the previous LED and PT(soldering on the wires) to test, it works well. Then I put all the parts on the board and solder them on, but after that, the analogy reading got problems. The serial monitor looks like this: | ||

| + | |||

| + | [[File:Analogue reading bad.png|600px]] | ||

| + | |||

| + | You can see the last line, the PCB stop working. I think it must be some problems when I desolder the pins, maybe the solder point affects the PCB routes, so I took a new PCB and solder all the wires on the pins, I did not desolder anything, it looks like this: | ||

| + | |||

| + | [[File:Solder on pins.png|300px]] | ||

| + | |||

| + | And after that, I also tested using the LED and PT(soldering on wires), they all work. Before solder the PT and LED on the PCB, I plug the PT on the holes, the analogue reading changes to 30-40, because it will detect the environmental light. But when I plug the LED on the board, the same problem occurred. There must be something wrong with the LED. | ||

| + | |||

| + | Now I have to test the performance of the LED. I connected the LED on the female-male jumper wire, and simply plug the jumper wire pins in the holes, it works, but when I connect the LED two legs on the hole, it stops working. | ||

| + | And when I put the LED to the end on the PCB, it works, it looks like the following thing: | ||

| + | |||

| + | [[File:LED to the end.png|400px]] | ||

| + | |||

| + | We thought it maybe because of the wires are not insulating, so we need to put heat shrink on the wires, after that, all the wires got heat shrink, the problem still there. We tried many times to change the position of the two LED legs, and we are sure that the two legs did not touch each other, but it still has the problem. | ||

| + | |||

| + | At last, we just use two jumper wires(without any pins) to connect the LED and the holes, and this method works. And when we shot the two jumper wires, it the same problem occurred. | ||

| + | |||

| + | So we thought there must be some problems with the two legs of LED and the PCB, and something internal made the LED short the whole circuit on the PCB. But we haven't find the problem. | ||

| + | |||

| + | Now we are thinking to just try to connect the jumper wires on the LED and PCB instead of directly connecting the two legs on the PCB. | ||

| + | |||

| + | To be continued........ | ||

| + | |||

| + | == 16th May 2020 == | ||

| + | |||

| + | During the past two days, we tested the sensors for many times, the results showed that when we connected the LED legs to the PCB holes, the whole PCB stopped working. And the weird thing is LED soldered on the jumper wires can work on the PCB. | ||

| + | |||

| + | We are thinking that maybe the problem is because too much current passing through the LED when the LED legs touch the PCB. So we use another Arduino UNO to supply the power of the board. We connected 3.3v on the UNO board, and other pins(TX, RX, RESET, GND) still connecting to the BoSL board, also we connected the GND of UNO and BoSL boards to make they have the same GND. | ||

| + | |||

| + | After that, we put LED in the PCB holes, it was working. | ||

| + | |||

| + | That means our hypothesis is right, the LED needs too much current and lets the BoSL board stop working. So we need to change the current of the LED. We tried to connect some resistor on the LED to see if it works. When we connected 100ohm resistor, it worked. And we need to try more smaller resistors to see which is the minimum value to keep the PCB working. From 100ohm to 1ohm, even 1ohm resistor can make the PCB working. But when we tried to use a 0ohm resistor, it did not work. So still the problem, why jumper wire work but 0ohm resistor did not work. We used the multimeter to measure the resistance of the jumper wire, we found the resistance of the jumper wire is 0.1ohm. So that means, the LED needs some resistance connecting to the holes, we cannot connect it directly to the PCB. | ||

| + | |||

| + | So we just solder a 1ohm resistor on the LED, and then solder it on the PCB. It can be seen like this: | ||

| + | |||

| + | [[File:Resistor soldered sensor.png|400px]] | ||

| + | |||

| + | And it was working. | ||

| + | |||

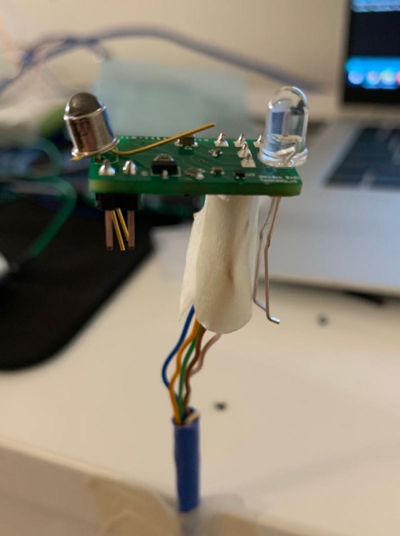

| + | Then we equip them in the case and did a quick testing, the sensor and results can be seen as following: | ||

| + | |||

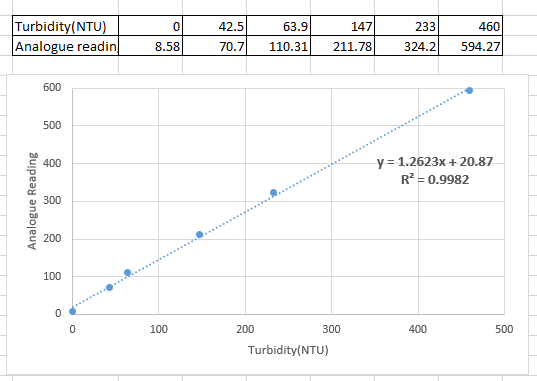

| + | [[File:PCB sensor in case.png|400px]] [[File:PCB first test.png|600px]] | ||

| + | |||

| + | As R square is 0.9982 which is not bad, this PCB works well. | ||

| + | |||

| + | The following steps we need to do are: | ||

| + | 1. redesign the sensor case, as we solder the resistor on the LED, so the current case is not big enough; | ||

| + | |||

| + | 2. to make the sensor waterproof and the PCB is fixed in the case; | ||

| + | |||

| + | 3. repeat the test in three different sensors to see the performance; | ||

| + | |||

| + | 4. redesign the PCB, add a resistor on the LED route. | ||

| + | |||

| + | To be continued...... | ||

| + | |||

| + | == 18th May 2020 == | ||

| + | |||

| + | Yesterday and today, we printed two new sensor cases and made two sensors, and then tested them in the real Turbidity solution. | ||

| + | |||

| + | ==== Sensors Making ==== | ||

| + | |||

| + | We designed two new sensor boxes, the new design allows the screws can be fixed inside the case. The new case and the lid can be seen like this: | ||

| + | |||

| + | [[File:Case v2 1.jpg|250px]] [[File:Case v2 2.jpg|250px]] | ||

| + | |||

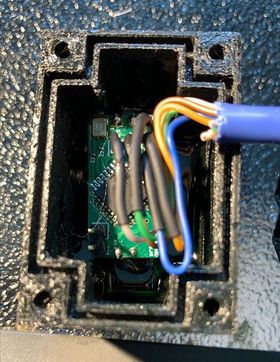

| + | Then we can place the sensor(PCB soldering LED and PT) in the case, and then seal the whole sensor in the case. There are two steps: 1. after placing the LED and the PT in the two holes, we inject some expoy into the case to make sure the LED and PT are fixed in the case; 2. after the epoxy became solid, we use a syringe to inject some silicone in the case(on the top of the epoxy) to make the whole sensor waterproof. We also need to ensure the wires are all in the silicone so that water won't goes inside the cable. | ||

| + | |||

| + | [[File:Case v2 3.jpg|300px|File:Case v2 3.jpg]] [[File:Case v2 4.jpg|280px|File:Case v2 4.jpg]] [[File:Case v2 5.jpg|300px|File:Case v2 5.jpg]] | ||

| + | |||

| + | After about 30 mins, when the silicone becomes sticky, we need to put the lid on the case, and also use the glue gun to seal the lid and also glue a cove on the surface of the case. We also use a M8 cable gland on the back lid to make sure the cable does not move at all. | ||

| + | |||

| + | [[File:Case v2 6.jpg|300px]] [[File:Case v2 7.jpg|300px]] | ||

| + | |||

| + | |||

| + | This design still has some drawbacks, we need to do some enhancement in the current design. | ||

| + | |||

| + | ==== Test the sensor==== | ||

| + | |||

| + | Now we got two sensors, use the same method to test the performance of the two sensors. | ||

| + | |||

| + | The two sensors' results can be seen as follows: | ||

| + | |||

| + | [[File:New sensor test results 2nd.png|500px]] | ||

| + | |||

| + | The results of the two sensors are almost the same, however the results still have differences with the previous ones, maybe because we change the case. | ||

| + | |||

| + | We need to do more test for the two sensors to make sure they work well. | ||

| + | |||

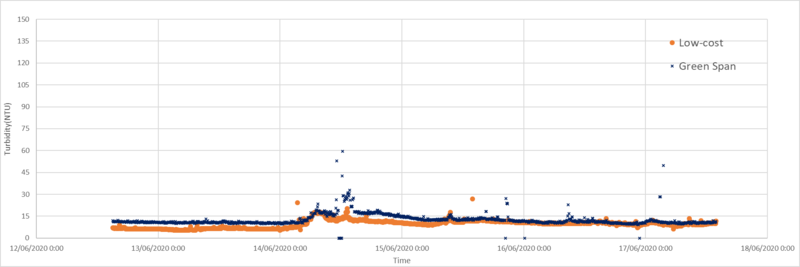

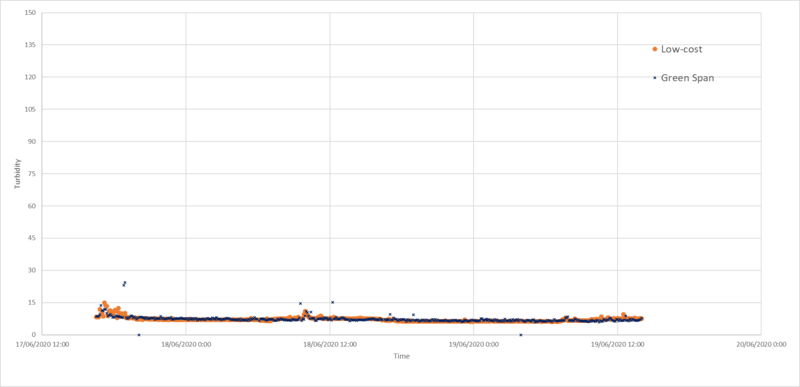

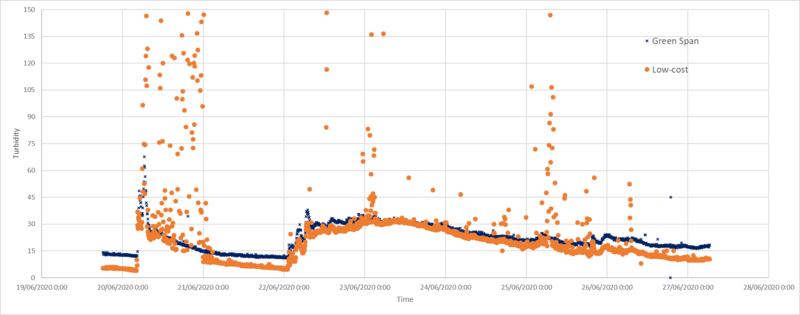

| + | == 26 May 2020 Sensor Installation== | ||

| + | |||

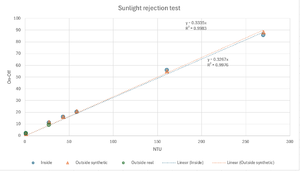

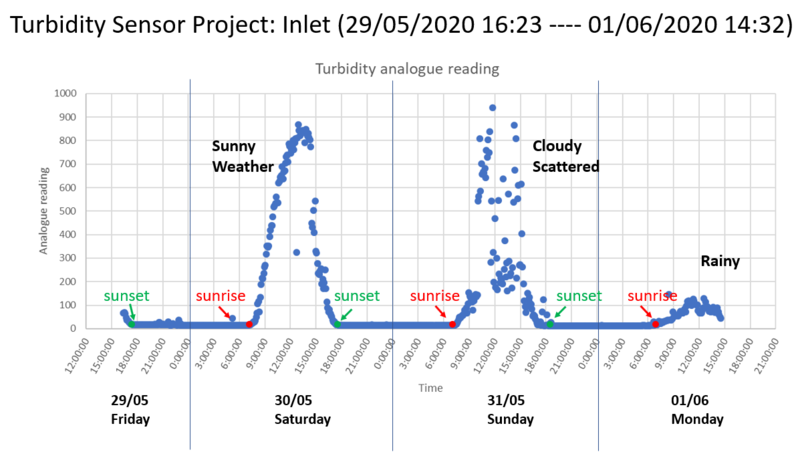

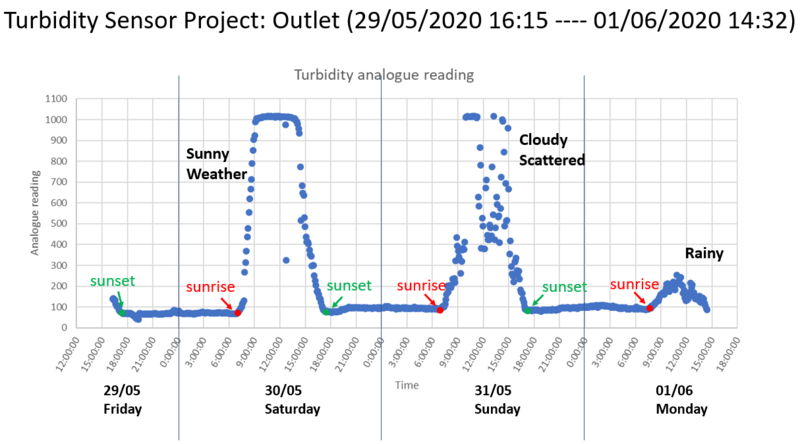

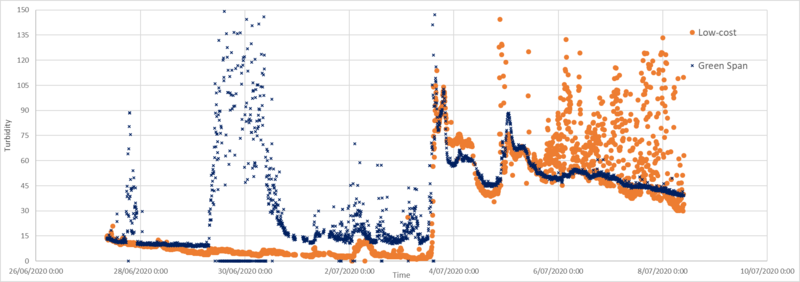

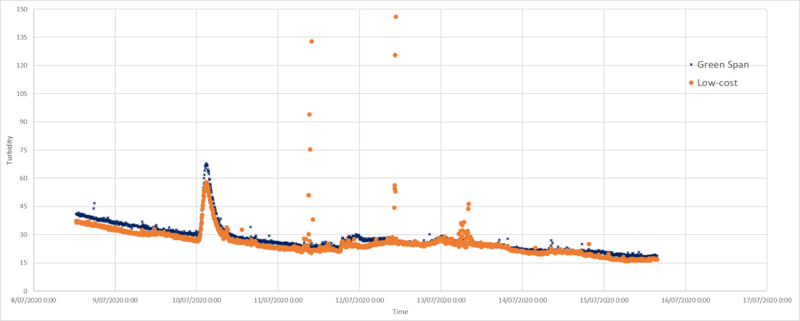

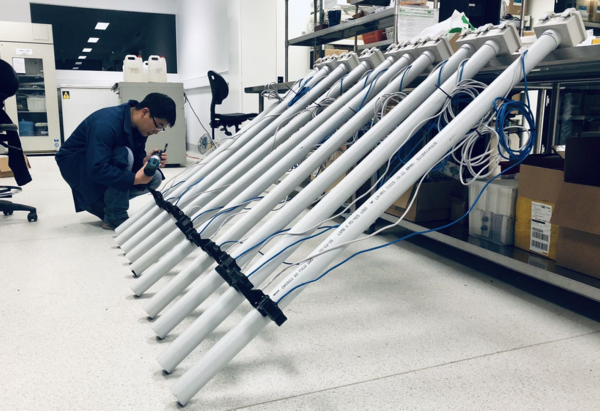

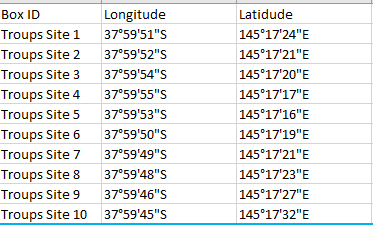

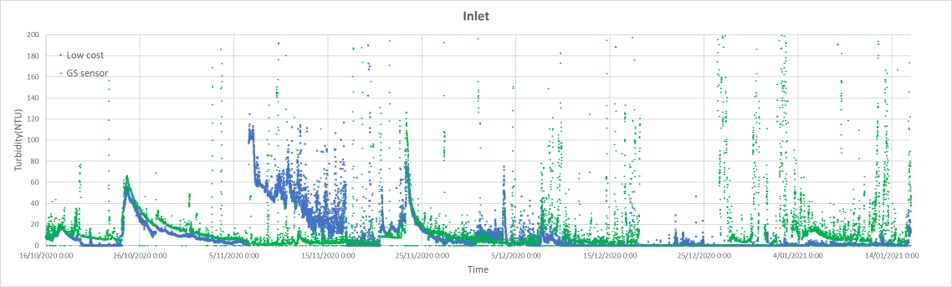

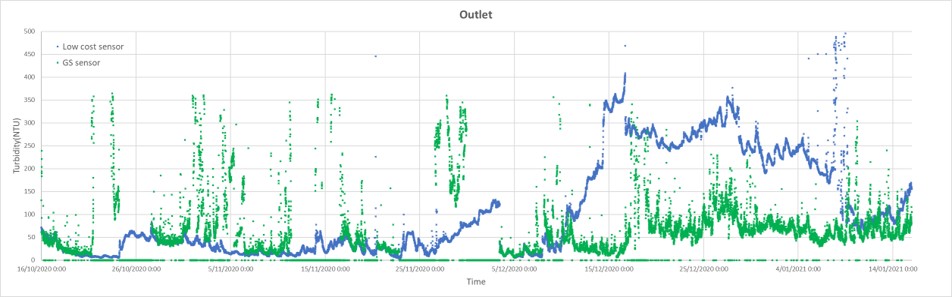

| + | Today we have installed the two turbidity sensors in Troups Creek Wetland, one at the inlet and another at the weir near the outlet. We also installed two greenspan turbidity sensor in the same position to compare the results. | ||

| + | |||

| + | ==== Inlet installation ==== | ||

| + | |||

| + | The inlet low-cost sensor was installed by fixing it on a piece of rectangular hollow section steel, and then fixed the steel on the sidewall. The low-cost sensor is facing the downstream of the water flow to protect the surface of the sensor. The BoSL board is put in a metal box and use a chain to fix on the sidewall to make it easy for maintenance. The data is transmitted to the website every 6 mins. | ||

| + | |||