Difference between revisions of "Spectrophotometer"

(→Result) |

|||

| Line 856: | Line 856: | ||

==== Result ==== | ==== Result ==== | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Result: | Result: | ||

<gallery> | <gallery> | ||

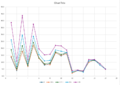

| − | File: | + | File:Spectra290424.png|Test for 100mm height FOV |

File:040924-4.png|Test for 200mm height FOV | File:040924-4.png|Test for 200mm height FOV | ||

</gallery> | </gallery> | ||

Revision as of 12:59, 26 May 2024

We have come up with a great idea to implement a low-cost spectroscopy sensor to measure various water quality parameters. The Sparkfun AS7265x spectroscopy sensor is introduced here (around AUD 60-100). It has three LEDS (VIS,UV,IR) which can measure the intensity for the wavelength ranging from 410nm to 940 nm. We would like to investigate any potential application with this sensor...

Contents

- 1 10/01/2023

- 2 25/01/2023

- 3 01/02/2023

- 4 01/02/2023

- 5 16/02/2023

- 6 09/03/2023

- 7 16/03/2023

- 8 23/03/2023

- 9 30/03/2023

- 10 07/05/2023

- 11 18/05/2023

- 12 15/01/2024

- 13 16/01/2024

- 14 22/01/2024

- 15 29/01/2024

- 16 18/02/2024

- 17 20/02/2024

- 18 22/02/2024

- 19 FOV - 29/02/2024

- 20 FOV - 08/04/2024

- 21 FOV - 09/04/2024

- 22 FOV - 29/04/2024

10/01/2023

Firstly, we hava come out an initial design for holding the sensor, and we use the clip to mount it to a vertical surface to do some preliminary tests.A black cup is 3D printed to store the water for measurement purpose.

It is good to know what roughly the spectroscopy for the water would be under low turbidty level. It can be seen that the sensor didn't receive much reflection for frequency between 710nm and 940nm.

25/01/2023

After the first design, we have come out some updated version for the stand that can hold the sensor instead of mounting to a cardbox. Now both the sensor and cup can be located in fixed position.And we have changed the colour of both cup and stand to be black to minimize the potential background noise.

This time we have using some different turbidty solution to measure the spectroscopy at each turbidty level.It can be seen that some correlation might exist at certain frequency (such as 610nm).

01/02/2023

Today,we bring all the equipment to the wet lab and would like to test again with same turbidty solution, while we have found something interesting:

It can be seen that large variation existed for the same measurement sample. We start thinking this might because of the light problem as the light in two rooms are different. And for now we just take one measurement reading with all LEDS on the sensors once to obtain the data. With strong light, the sensor might not be able to receive the correct reflection from the surface. So we need to get some improvements for our code to count for the background noise effect.

01/02/2023

We have modified our code to include a initial scan without using LEDs, this spectroscopy reading is later used as background reference.For now, we try to use the spectroscopy that got with all LEDs minus the spectroscopy that got without LEDs to get our final spectroscopy. We have selected three test locations:

1) Office (Normal Light Condition) 2) Wet lab (Strong Light Condition) 3)Table outside the office (Slight Light Condition)

The results looks pretty good as the spectroscopy obtained at different locations are very close to each other, the background noise has been reduced.

Later, we have also let the sensor stands on different surface to see whether this will affect the spectroscopy of the detected object. The surface we selected are:

1) Office Desk (White Surface) 2) Laptop (Grey Surface) 3) IOT Poster (Colourful Surface)

The spectroscopy obtained from three different back surfaces aligned well with each other. Now we would like to continue testing the water with different turbidty level again.

16/02/2023

Today we have found that the sensor case we designed originally is not aligned in the middle of the black cup. We have modified our design for both the sensor case and stand:

This stand have two trenches that we can adjust the sensor height in the future while maintain its stay in horizontal surface. And the arduino board has been locked on the top of the stand. A pre-cut circle surface is designed at the bottom of the stand that can fit the size of the cup,so that we can easily get the black cup out and in, making the filling progress more easier:

With this new design, we have tested it with all the turbidty solution again:

09/03/2023

We have modified the container up to a black square box to maximize its capacity for carrying water.

Also, we have updated the sensor reading function, now the sensor can read the spectroscopy information from White, IR, UV and All LEDs together separately. This could help us better understand how different objects behaves to different LEDs).

For the experiment settings, we have added cardboard as the cover when we do the experiment to eliminate the effect of other light resources.

Four different turbidity solutions (60NTU, 100NTU, 200NTU, 400NTU) has been tested after five minutes settle time.The results (average of 6 times reading) are shown as follows:

16/03/2023

We have extended our reference turbidity sets to a larger level:

| Turbidity | Values |

|---|---|

| Low Turbidity Level | 0,0.61,0.68,1.23 |

| Mid Turbidity Level | 25,50,55.5,75,108 |

| High Turbidity Level | 199,300,393 |

We have then followed the same experiment procedure and have obtained the spectroscopy for the above 12 turbidity levels. After got the spectroscopy, we have started to look at if there is any correlation existed between turbidity level and normalized signal value.

White Light:

UV Light:

IR Light:

All LEDs:

For the IR, we didn't get any good correlation curve so it has been eliminated from the model.

After establish a few relationship curve ( overall above 90% for turbidity ranging from 0 to 300 NTU), We have started to establish a initial prediction model to see if we can predict the turbidity level:

| LEDs | Wavelength | Regression Curve |

|---|---|---|

| White | 485 nm | y= 34.431x-342 |

| UV | 410 nm | y= 4.7096x-249.06 |

| UV | 435 nm | y= 24.651x-231.34 |

| All | 435 nm | y= 16.582x-303.02 |

| All | 485 nm | y= 32.224x-340.19 |

Later we have brought three water samples from Troups Creek Retention pond to see if we can actually predict the turbidity level, the output value are compared with the reference value that obtained from the Thermo Scientific Turbidity Sensor (ORION A14500), the results are shown as follows:

From the result here, it can be seen that the best predict regression curve is using white LED at 485nm, with uncertainty generally under 30%. For some instance, the model could able to predict good turbidity level (the one marked as green), but it didn't occurred constantly under same LED condition. It is suggest further dataset might be needed to be fit into the predict model, and it needs to come up with a way that can reduce the uncertainty caused by the sensor.

23/03/2023

In this week, we would like to test the impact of light (with or without cover box) and the impact of different height (the distance from the water surface)

Impact of Light

Experiment Setup

The experiment is conducted with and without cover box after 5-mins setting up time.

6 different turbidity solutions were used:

| Turbidity | Values |

|---|---|

| Low Turbidity Level | 0 |

| Mid Turbidity Level | 50,75,100 |

| High Turbidity Level | 199,300 |

Result

The results shown here are calculated based on the difference between without case value with with case value.

The grey block shows the 5 reference points we selected previously.

The yellow blocks shows some new value which comes out when we did not use the cover.

Conclusion

Overall, when look at the 5 reference points, the difference is not significant ( error rate < 20%). This result is not so bad as the sensor itself has around +/-12% accuracy (https://www.sparkfun.com/products/15050).

Except for those extreme error points(100% error rate), overall, the error is under 35% when turbidity under 100 NTU and under 50% when turbidity ranging from 100 to 300 NTU.

Impact of Height

Experiment Setup

The height defined here is referring to the height from the water surface to the edge of the sensor case. The height for previous experiment is 95mm.

The experiment is conducted with cover box after 5-mins setting up time.

We have conducted another two height at 35mm and 135mm (the minimum and maxmimum value we could reach for current stand). 6 different turbidity solutions were used:

| Turbidity | Values |

|---|---|

| Low Turbidity Level | 0 |

| Mid Turbidity Level | 50,75,100 |

| High Turbidity Level | 199,300 |

Result

5 Reference Points:

LEDs:

Conclusion

When look at the 5 reference points, it can be seen clearly that better correlation relationship can be achieved when the height increased.

When look at each LED individually, better correlation could be achieved at lower wavelength if the height is increased.

Generally, the best relationship is still achieved at higher height (correlation above 97% for White, UV and All LEDs with height of 135mm).

30/03/2023

In this week, we would like to continue test the impact of light (with or without cover box) and the impact of different height (the distance from the water surface)

Impact of Light

Experiment Setup

The experiment is conducted with and without cover box after 5-mins setting up time for same turbidity solution.

6 different turbidity solutions were used:

| Turbidity | Values |

|---|---|

| Low Turbidity Level | 0 |

| Mid Turbidity Level | 50,75,100 |

| High Turbidity Level | 199,300 |

Result

The results shown here are box plot for White, UV and all LED conditions.

Conclusion

Overall, the variation between with and without cover is not very significant.

Generally, when look at all LEDs and White LED, with-cover readings tend to be larger than the without-cover readings. For the UV LED only, the difference is not significant.

Impact of Height

Experiment Setup

The height defined here is referring to the height from the water surface to the edge of the sensor case.

As we would like to explore the how high the sensor could be able to provide valuable data, a 1000 mm long bar was used, thus no cover was used in this experiment.

The experiment is conducted after 5-mins setting up time for each turbidity solution.

We have conducted in total five different heights ranging from 25mm (Just above the water surface and 725mm:

| Height | 25,225,425,625,725 (mm) |

|---|

3 different turbidity solutions were used:

| Turbidity | Values |

|---|---|

| Low Turbidity Level | 0 |

| Mid Turbidity Level | 100 |

| High Turbidity Level | 300 |

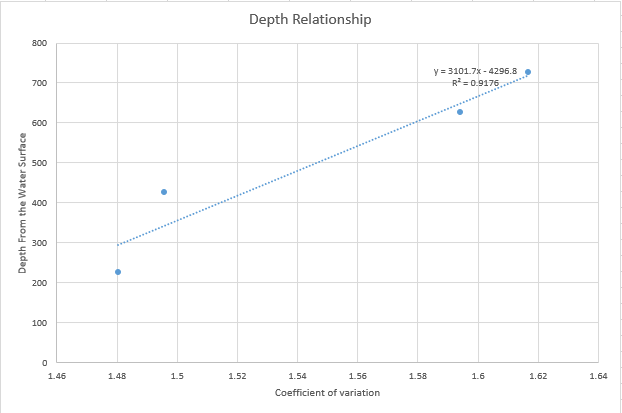

Result

The results here were analyzed using coefficient of variation for each turbidity and individual LED condition. Then the average coefficient of variation value were taken by average all the readings at certain depth.

The results are shown here:

| Coefficient of Variation | Values |

|---|---|

| 25mm | 1.86 |

| 225mm | 1.48 |

| 425mm | 1.49 |

| 625mm | 1.59 |

| 725mm | 1.61 |

It can be seen that when the sensor is very close to the water surface, the variation is very huge, thus hard to find the potential depth relationship, by remove the 25mm value for now, and use the rest value to plot a regression curve, the depth relationship can be found as:

Conclusion

This result could illustrate the potential of using spectrometer sensor as a depth sensor. More height experiments are needed to further approve this concept.

07/05/2023

During the past period, we were aiming to investigate the potential of using two spectrometer sensors to see whether it can increase the accuracy of our data. The Sparkfun Qwwic Mux port is used to connect two Sparkfun AS7265X spectrometer sensors.

Experiment Setup

The experiment is conducted without cover box at 95mm height after 5-mins setting up time for same turbidity solution. The set up configuration is shown as below:

For the first trial, the angle between two spectrometer sensors is set as 90 degree.

5 different turbidity solutions were used:

| Turbidity | Values |

|---|---|

| Low Turbidity Level | 0 |

| Mid Turbidity Level | 50,75,100 |

| High Turbidity Level | 199 |

Result

The spectroscopy graph of White LED is shown as follow and the best correlation relationship between turbidity level and normalized sensor reading can be found at 460nm wavelength.

The spectroscopy graph of UV LED is shown as follow and the best correlation relationship between turbidity level and normalized sensor reading can be found at 410nm wavelength.

The spectroscopy graph of All LEDs is shown as follow and the best correlation relationship between turbidity level and normalized sensor reading can be found at 860nm wavelength.

Conclusion

From the result, it can be shown that the dual Spectrosensor can get the better correlation relationship up to 97% for UV / White and All LEDs condition.

For the next experiment, we will adjust the angles between two sensors to let it have good reflectance over the water surface.

18/05/2023

Following the last experiment, we would like to continue investigate more parameters which may affect the spectrophotometer. In this experiment, we have adjusted the angle between two sensors and would like to let the receiver sensor can receive the light that sender sensor emitted reflected back from water surface.

Experiment Setup

The experiment is conducted without cover box at 90mm height after 5-mins setting up time for same turbidity solution. The set up configuration is shown as below:

The angle between two spectrometer sensors is therefore set as 130 degree.

5 different turbidity solutions were used:

| Turbidity | Values |

|---|---|

| Low Turbidity Level | 0 |

| Mid Turbidity Level | 50,75,100 |

| High Turbidity Level | 199 |

Result

The spectrum graph of White LED is shown as follow and the best correlation relationship between turbidity level and normalized sensor reading can be found at 560nm wavelength.

The spectrum graph of UV LED is shown as follow and the best correlation relationship between turbidity level and normalized sensor reading can be found at 410nm wavelength.

The spectrum graph of All LEDs is shown as follow and the best correlation relationship between turbidity level and normalized sensor reading can be found at 645nm wavelength.

Conclusion

From this experiment, the correlation we get from White, UV and All LEDs is not good as before, with 79%, 72% and 96%, respectively.

While look at the spectrum, it can be seen that the resolution get from this experiment is also worse than before.

15/01/2024

Before continue to explore full capbility of the module, the settings and performance of the sensors have been re-assessed. From user guide, the user could be able to change:

Measurement Mode: 6 Chan One Shot (Default), this generally take readings from six out of six photodiodes from each sensor, which suit for our purpose.

Gain:64X (Default), this value can be up to 64X if value from the sensor are exceeded the limit.

Integration Time: integer input ranging from 0 to 255, 1 integer equals to 2.8ms. Increase 1 integer can increase 1024 sensitivity. To reach maximum sensitivity of the sensor (65545), the integer of the integration time needs to be at least 49.

Light Source:User can choose to use LED or not use LED.

Function: User can choose to use Raw reading function or Calibrated reading function. Since the calibrated function needs to be performed within certain condition, which is not suit for our purpose, the raw reading function is used for future development.

16/01/2024

Next, we would like to let the sensor capable of recording the spectra without using LED under office light or sunlight condition. This step can help for further sensor calibration.

Experiment Setup

| Settings | Input |

|---|---|

| Integration Time Integer(cycles) | 49 |

| Measurement Mode | 6CHAN_ONE_SHOT |

| Light Source | Non-LED |

| Function | Example 4 (reading Raw Values) from library. |

| Gain | 1X |

| Location | Office Desk |

Result

| A | B | C | D | E | F | G | H | R | I | S | J | T | U | V | W | K | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 39 | 16 | 0 | 79 | 0 | 109 | 142 | 143 | 91 | 8 | 4 | 7 | 4 | 15 | 4 | 1 | 1 |

Conclusion

From this experiment, it can be seen that 0 values occured at D (485nm) and F (535nm), we need further research to solve this problem.

22/01/2024

To figure out why the zero occured, the integration time is first reason we could think about. So we start to add delay after the measurement function and before the serial.print to see what happened.

Experiment Setup

| Settings | Input |

|---|---|

| Integration Time Integer (cycles) | 49 |

| Measurement Mode | 6CHAN_ONE_SHOT |

| Light Source | Non-LED |

| Function | Example 4 (reading Raw Values) from library. |

| Gain | 64X |

| Location | Office Desk |

Result

When the delay less than 72ms:

| A | B | C | D | E | F | G | H | R | I | S | J | T | U | V | W | K | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 40 | 17 | 0 | 80 | 37 | 112 | 143 | 142 | 91 | 9 | 5 | 7 | 4 | 15 | 4 | 1 | 1 |

When the delay at 100ms:

| A | B | C | D | E | F | G | H | R | I | S | J | T | U | V | W | K | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 39 | 16 | 52 | 79 | 34 | 109 | 142 | 143 | 91 | 8 | 4 | 7 | 4 | 15 | 4 | 1 | 1 |

Conclusion

From this experiment, we found that when adding certain time of delay, the zero problem get solved. We hypotheisted that the sensor needs to take some time to complete the spectra conversion. Further work is required to verify this hypothesis.

29/01/2024

The zero issue has been re-assesed. We started to create an array to store first 20 readings from same channel output to see what will happened. This step was repeated for all 18 channels.

Experiment Setup

| Settings | Input |

|---|---|

| Integration Time Integer (cycles) | 49 |

| Measurement Mode | 6CHAN_ONE_SHOT |

| Light Source | Non-LED |

| Function | |

| Gain | 64X |

| Location | Office Desk |

Result

After 20 interations, we found that for channel D,F,R,J,W,L. The zero was observed for first 3-5 cycles of reading, after that, we can get stable readings. For remaining 12 channels, we can get good readings from the beginning.Therefore, for this six channels, we started to use millus() function to record the time it needs from take measurement until record the data, the result is shown below:

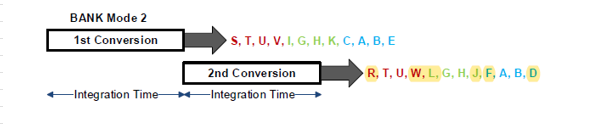

It can be seen that for all these 6 channels, it generally required 80-90 ms to shown the data. Thus, we re-investigate the user guide and found this is related to the spectral conversion of the data itself:

All these 6 channels all within 2nd conversion zone of the sensor, which means they will need 2 * integration time to complete data conversion. For an integration time integer of 49, this means it will require (49+1)*2.8*2 = 280 ms at least. We use millus() to record the time that "takeMeasurement()" required, which is 225ms, this means it generally require extra 55 ms to complete spectral conversion, the recorded time is generally 30ms larger than the calculated time difference. That's why the zero readings will occur.

To verify our findings, we also tried smaller integration time (integration time integer 29):

We could observe similar trend that for integration time intger of 29 ( integration time is 84ms), the time for measurement takes 140ms, thus 2*integration time (84ms) - 140 would come out 28ms. The results suggest the similar conclusion as above that the sensor needs 30ms + calculated time difference.

A second Way of verify this is simply change the output order from the example, originally is from A to L as shown below:

A,B,C,D,E,F,G,H,R,I,S,J,T,U,V,W,K,L

We re-order this and let and let that 6 channels to be the last, it become:

A,B,C,E,G,H,I,S,T,U,V,K,D,F,R,J,W,L

We will observe:

| A | B | C | D | E | F | G | H | R | I | S | J | T | U | V | W | K | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 18 | 45 | 247 | 0 | 108 | 0 | 183 | 241 | 559 | 205 | 146 | 132 | 25 | 17 | 21 | 10 | 11 | 5 |

| A | B | C | E | G | H | I | S | T | U | V | K | D | F | R | J | W | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 19 | 44 | 232 | 107 | 182 | 235 | 215 | 148 | 25 | 16 | 21 | 10 | 183 | 92 | 563 | 138 | 10 | 4 |

This matches what we want as it allows more time for the sensor to complete data conversion.

Conclusion

The above two ways of experiments verify our hypothesis that the sensor needs double integration time to complete spectral conversion. This time increases when the integration time increases. Re-order the output matrix is suggested for future data processing.

18/02/2024

After fixing the zero-issue, now we begin from investigating the effect from different light sources. We re-do the experiments in a more systematic way.

Experiment Setup

| Settings | Input |

|---|---|

| Integration Time Integer (cycles) | 49 |

| Measurement Mode | 6CHAN_ONE_SHOT |

| Light Source | Non-LED and LED |

| Function | |

| Gain | 64X |

| Location | Office Desk / Dark Environment / Sunlight |

The experiment set-up is shown as follows:

Result

The average spectra were taken as avaergae of 10 readings.

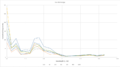

The results obtained under different light conditions are:

Conclusion

It can be seen that under the office light and dark environment, very similar spectra can be obtained by using the substracting method. While for sunlight condition, the counts received by the sensor is much larger than other conditions. We might need to introduce dual sensor ( one facing up and one facing down) to solve this issue.

20/02/2024

Previous Experiment found the substracting method works well in moderate light condition as well as dark condition. While under sunlight, this method is invalid. We would like to change some of the sensor settings to see if we could get similar spectra.

Hypothesis

The light effects can be counted by subtracting the background noise or accounting for the sunlight irradiance to get similar spectra with spectra got with office light or dark environment.

Action Items

- Set up a completely dark environment and under office light Condition , prepare the sensor case without diffuser.

- Set up the sensor case without diffuser under the direct sunlight.

- Set up Purple Card

- Fix the sensor at certain height. (e.g. 75mm from the water surface from previous experimental settings)

- Shining the object without using LED, record the Raw DN output from the sensor (Default Settings), take 6 readings and take average spectra.

- Shining the LED for the object, record the Raw DN output from the sensor (Default Settings), take 6 readings and take average spectra.

- Letting One sensor facing up towards the sun and record the raw DN output from the sensor (Default settings), take 6 readings and take average spectra.

- Using step 5 result minus step 4 result.

- Change integration time and Gain to adjust the sensor DN output.

- Check the difference between various Test Conditions.

Result

The average spectra were taken as avaergae of 6 readings.

Conclusion

From the result, it can be seen that:

Under default settings, the 64x gain would lead to maximum readings (65545), which would lead to 0 output if you using subtracting method.

The sensor output cannot be achieved easily by changing the gain or integration time.

22/02/2024

Explore the potential of using Spectro sensor to detect turbidity in urban water samples.

Hypothesis

The Spectro sensor has good correlation with turbidity.

Action Items

- Set up the sensor with sensor case without diffuser, fixed the sensor at highest height of the stand.

- Prepare the black PLA+ tray

- Prepare different turbidity solution, using the turbidity meter to remeasure the concentration of the solution.

- Using subtracting method to get the spectra DN output readings from the sensor. The final reading was achieved by averaging six readings.

- Repeat the above process for five different solutions, collect the data and analysis the data.

Result

The average spectra were taken as average of 6 readings.

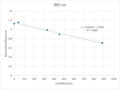

The normalized response (DN at specific channel/average of 18 channels total DN) of the reading at 860nm is selected to show the correlation due to turbidity is found to be more sensitive in NIR band:

Conclusion

It can be seen that both model can achieve good correlation with turbidity (>95%). However, since the sample size is quite small (n=5) and we were testing against standard turbidity solution( which consist of white particles which tend to have better reflection properties than the normal environment sample), we would need to extend our dataset to larger scope to verify our model.

FOV - 29/02/2024

We are worried the edge of the sensor case is too small that would affect the measurement reading.

Hypothesis

Our reading would be impacted by the field of view due to wrong design of the sensor case

Action Items

For upward Sensor:

- Take off the lid from top of the sensor case, take the measurement from the upward sensor facing the office light

- Normalized spectra and compare the result with previous readings.

For downward Sensor:

- Fix the sensor with the pole at 20 cm and 40cm.

- Prepare different settings include: with original case, with ground glass diffuser, with white diffuser and without any casing.

- Observe the lighting pattern and compare the results.

Result

The Upward Sensor:

The Downward Sensor:

Conclusion

The result shows very similar readings, major difference observed for wavelength ranging from 550-600 nm. This result would indicate that the field of view didn’t been effected by the size of the cover when not using LED. Further test may need to be done for the downward sensor.

As for the downward sensor, it can be seen that the field of view is impacted by the current case design. The ground glass diffuser for now looks work better than the white diffuser based on the criteria that we want the light to be concentrated and bright. The next step would be expand the size of the sensor case.

FOV - 08/04/2024

Hypothesis

The FOV is changing together with the increasing of height

Action Items

- Select big enough object —- Green grass and the concrete has been selected.

- Change height (10cm, 50cm, 100cm)

- Take 5 readings, get the average spectra and compute the normalized spectra based on the average spectra reading.

- Observe normalized average readings

Result

Conclusion

From the result, it can be seen that generally the normalized response for different heights were kept roughly same for grass and slight difference observed for the concrete. Two normalized spectra indicate that the sensor can still receive valuable signal within 1m height.

This means if FOV is large enough, the height shouldn’t affect the sensor readings. This means previous settings have limited the FOV, which we should aim for a larger tray or limit the ROI.

Next step would be to compute what the actual FOV area would be based on the information from the datasheet.

FOV - 09/04/2024

We are worried the edge of the sensor case is too small that would affect the measurement reading. Previous V2 experiment has verified that the height shouldn’t have huge impact on the sensor readings. So now we would like to investigate what the actual field of view of the sensor is.

Hypothesis

Our reading would be impacted by the field of view

Action Items

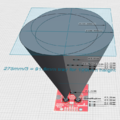

- Modelling the potential field of view area using the shaper 3D. (Scale 3x in shaper 3D)

- Record the area for the FOV

- Find the regression curve which we could use for the future analysis.

- Do quick test to verify the findings.

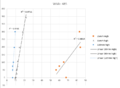

Result

Result:

Conclusion

From the result, it can be seen that when the object is within the FOV (middle position), it generally distinguished from other spectra, this is what we want, as this quick test partly

FOV - 29/04/2024

To prove the hypothesis from FOV we did before

Hypothesis

The FOV is same as we found from previous simulation.

Action Items

- Putting the whole setup in the dark environment.

- Shine the LED to take measurements, record the raw readings with and without LED.

- Prepare paper with black circle in the middle just match the size of the hypothesis size.

- The hypothesis size is taken as the equivalent circle of the previous simulated area. For 160mm height, the diameter is 136mm, 100mm height is 90mm.

- Two sets of size have been prepared: For highest setup (160mm height), the size is 200mm,167mm,136mm,100mm,50mm and 20mm.

- For another setup (100mm height), the size is 167mm, 100mm, 90 mm, 50mm and 20mm.

- The final spectra was obtained by using the LED spectra minus the spectra without LED to account for the sensor noise itself caused. Final spectra was taken as the average of 6 readings.

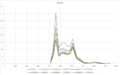

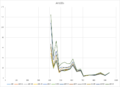

Result

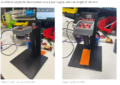

Our model is built like following:

Experimental Setup:

Result:

Conclusion

According to previous simulation, when the height is at 100 mm, the FOV would equivalent to a circle with 90mm diameter. So look at the 90mm, theoretically, spectra for circles larger than or equal to 90mm should have same spectra. Generally, the result matches this theory, with small offset observed at 460nm and around 650nm. For the circle within the FOV (<90mm), obvious difference observed for 50mm diameter circle and 20mm diameter circle.

When look at higher height (160mm), according to the function, the FOV should be 136mm. Spectra for circles larger than or equal to 136mm should have same spectra. This is generally true as well, while offset also observed at 460nm and 650nm. For the circles within the FOV (<136mm), difference can be observed for 100mm, 50mm and 200mm diameter circle.

In conclusion, this black circle test could prove our hypothesis that the FOV proposed previously is correct and we should take further steps to account for this FOV issue. There are two ways to solve it: 1) Develop complex optical system to narrow down the FOV 2) Develop a buoy system that the sensor will be kept at a relative constant height against the water surface. Both options would be explored.