Difference between revisions of "BoSL Bead Beater"

| Line 1: | Line 1: | ||

| − | This section shows the BoSL bead beater | + | This section shows the BoSL bead beater. |

| − | The BoSL bead beater is a low-cost, open-source, freely available 3d printed bead beater for DNA and RNA extraction. The device can fit with any commercially available portable jigsaw, the 3D-printed components can extract six samples at a time and the bead beating function is achieved by driving the sample through the rapid movement of the jigsaw blade. | + | The BoSL bead beater is a low-cost, open-source, freely available 3d printed bead beater for DNA and RNA extraction. The device can fit with any commercially available portable jigsaw, the 3D-printed components can extract six samples at a time, and the bead beating function is achieved by driving the sample through the rapid movement of the jigsaw blade. |

| + | |||

| + | == Latest Design == | ||

| + | |||

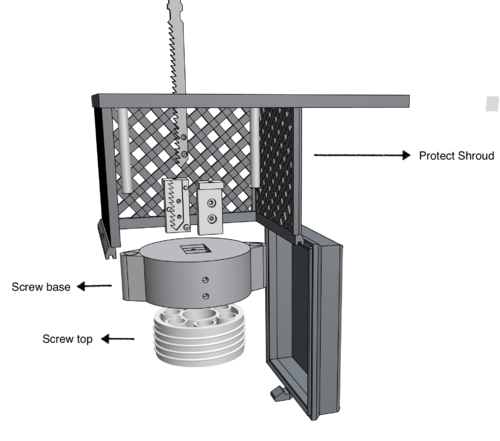

| + | [[File:Final version.png|500px|center|Final Version]] | ||

| + | |||

== Design Journey == | == Design Journey == | ||

| − | ===''''' | + | ==='''''Version 1'''''=== |

At the start, the initial design key points are <br> | At the start, the initial design key points are <br> | ||

| Line 21: | Line 26: | ||

For this design, we found that the blade was easily dropped out from the cylindrical clamp component, and the connection parts between the screw base and clamp component were easy to break. Therefore durability of this design was not good. Also, the total length of the design was too long, it causes too much horizontal vibration. | For this design, we found that the blade was easily dropped out from the cylindrical clamp component, and the connection parts between the screw base and clamp component were easy to break. Therefore durability of this design was not good. Also, the total length of the design was too long, it causes too much horizontal vibration. | ||

| − | ===''''' | + | ==='''''Version 2'''''=== |

Some further changes were made that combined the connection parts with the screw base. At the same time, invert the cylindrical portion under the screw case and decrease the overall length by inserting the blade part into the screw top. | Some further changes were made that combined the connection parts with the screw base. At the same time, invert the cylindrical portion under the screw case and decrease the overall length by inserting the blade part into the screw top. | ||

| Line 39: | Line 44: | ||

Compared with the first design, this was relatively stable, but the blade still easily fell off. Simultaneously, the side connection parts were too cumbersome, and the overall design was too heavy, which led to horizontal wobble still exists. | Compared with the first design, this was relatively stable, but the blade still easily fell off. Simultaneously, the side connection parts were too cumbersome, and the overall design was too heavy, which led to horizontal wobble still exists. | ||

| − | ===''''' | + | ==='''''Version 3'''''=== |

To reduce the weight of the whole design, the screw top is changed to a hollow design and remove the redundant part. | To reduce the weight of the whole design, the screw top is changed to a hollow design and remove the redundant part. | ||

| Line 57: | Line 62: | ||

However, although the horizontal wobble is significantly reduced by reducing the overall weight, the wobble still exists, and the wobble from side to side may lead to blade breakage. | However, although the horizontal wobble is significantly reduced by reducing the overall weight, the wobble still exists, and the wobble from side to side may lead to blade breakage. | ||

| − | |||

| − | |||

Revision as of 00:04, 5 December 2022

This section shows the BoSL bead beater. The BoSL bead beater is a low-cost, open-source, freely available 3d printed bead beater for DNA and RNA extraction. The device can fit with any commercially available portable jigsaw, the 3D-printed components can extract six samples at a time, and the bead beating function is achieved by driving the sample through the rapid movement of the jigsaw blade.

Latest Design

Design Journey

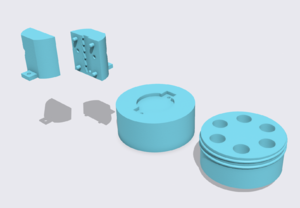

Version 1

At the start, the initial design key points are

- Using a screw base and top to hold the extraction sample.

- Connection parts to connect the jigsaw blade and screw base.

Firstly, we made a circular screw base and top with a 64mm diameter and 6 sample placement holes. Meanwhile, a two-piece cylindrical clamp component clutched the jigsaw blade with studs and M4 screws. Then that cylindrical component is connected to the screw base by using two M4 screws.

Results & Findings

For this design, we found that the blade was easily dropped out from the cylindrical clamp component, and the connection parts between the screw base and clamp component were easy to break. Therefore durability of this design was not good. Also, the total length of the design was too long, it causes too much horizontal vibration.

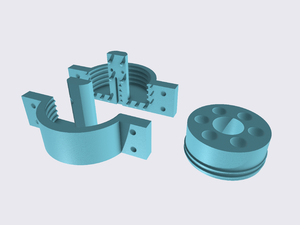

Version 2

Some further changes were made that combined the connection parts with the screw base. At the same time, invert the cylindrical portion under the screw case and decrease the overall length by inserting the blade part into the screw top. The screw base is divided into two parts with the addition of "studs" on the connecting surface in the middle. These two pieces can be combined with "studs" and used to fasten the jigsaw blade with M4 screws.

Also, a hole was carved in the middle of the screw top to ensure that the extension part of the screw base could be passed and screwed perfectly.

Results & Findings

Compared with the first design, this was relatively stable, but the blade still easily fell off. Simultaneously, the side connection parts were too cumbersome, and the overall design was too heavy, which led to horizontal wobble still exists.

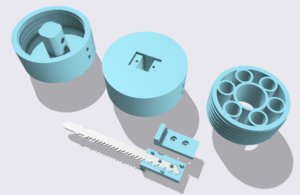

Version 3

To reduce the weight of the whole design, the screw top is changed to a hollow design and remove the redundant part. The screw base was also modified by replacing the split design with an insertion design. The blade was perforated and fastened by two small clips and then inserted into the screw base and secured by M3 screws on the side.

Results & Findings

The design of connecting the blade and the screw top by screws greatly improves the durability of the device. At the same time, the hollow design for the screw top also greatly reduced the weight of the whole device, well reduced the horizontal wobble during operation.

However, although the horizontal wobble is significantly reduced by reducing the overall weight, the wobble still exists, and the wobble from side to side may lead to blade breakage.